Product Description

high precision custommized helical gear shaft drive shaft reducer Gear Shaft

Product Description

Hyton provides one-stop solution service for your metallurgical equipment spare parts, currently we produce rolling mill rolls, guide, blades, gears, sprocket wheels, worm, worm gears, flange processing parts, welding processing parts and etc.Gear rack is a rotating machine part with cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. It includes spur gear, helical gear, skew gear, bevel gear, spiral bevel gear and so on. It is widely used for all kinds of machinery equipment.

| Product Name | Gear Racks |

| Material | C45, 40Cr, 20CrMnTi, 42CrMo, Copper, Stainless steel |

| Tolerance | 0.001mm – 0.01mm – 0.1mm |

| Tooth Hardness | 50-60 HRC |

| Length | Customized |

| Processing | Forging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment |

| Inspection | Material Report, Dimensions Checking Report, Hardness Report |

| Payment | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Lead Time | 4 weeks |

Company Profile

HangZhou CZPT Heavy Industry Technology Development Co., Ltd. is a leading enterprise in the wear-resistant casting of large engineering machinery and the forging of large equipment parts located in the New Material Industrial Park, Xihu (West Lake) Dis. High-Tech Zone, HangZhou City, the company covers an area of 90 Square kilometer and currently has more than 300 employees. The company is equipped with lost molding production line and lost casting production line imported from FATA Company in Italy, Inductotherm Vacuum Degassing Furnace(USA), Foseco Casting Technology(U.K), SPECTRO Spectrometer (Germany), the currently most advanced ZZ418A vertical parting flaskless shoot squeeze molding machine Disa production line, horizontal molding line and self-control lost casting production line in China, the most advanced sand treatment system in China. With 3 gas trolley heat treatment CZPT and pusher-type CZPT full-automatic heat treatment production lines, the company can annually produce 30,000 tons of various wear-resisting castings and metallurgical equipment forging parts.

Manufacturing Technique

Inspection

Dimension Measurement

According to the product drawings provided by customers, we will conduct strict dimensional inspection before the products are shipped.

Hardness TestAccording to the drawing requirements provided by customers, we will conduct hardness inspection before the products are shipped.

Roughness MeasurementAccording to the drawing requirements provided by customers, we will conduct roughness inspection before the products are shipped.

Packing and Shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. After goods well packaged, we need only 1 day ship goods to ZheJiang port, which means that most of the spare parts you bought from Hyton, it will get your port within 45 days all around the world if shipment by sea.

Our Advantages

1)Your inquiry related to our product & price will be rapidly.

2) Well trained & experienced staff are to answer all your inquiries in English of course.

3) Your business relationship with us will be confidential to any third party.

4) One stop purchase service: extensive rang of products for qualified offering.

5) We response to client’s inquiry within 12 hours.

FAQ

1.Q: What kind of products do you make?

A: We specialize in metallurgical equipment casting and forging parts, such as forging rolls, guide, blades, gears, sprocket wheels, worm, worm gears, flange processing parts, welding processing parts and etc.

2.Q: What kind of material do you offer?

A: High manganese steel, high chrome iron, alloy steel, low carbon steel, medium carbon steel, Stainless Steel and etc.

3.Q: What is your time of delivery?

A: Our lead time is generally 2-4 weeks for casting parts and shipping time is about 2-4 weeks.

4.Q: How to test your quality?

A: We will show you material inspection and measurement inspection after fininsh the goods, at the same time, we will give you the life time guarantee letter after shipping the goods. The best suggestion to all the customer who may interest our product-Test 2 set first, all the good business relationship all from test and trust.

| Hardness: | Hardened Tooth Surface |

|---|---|

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Type: | Circular Gear |

| Customization: |

Available

| Customized Request |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

Can you provide real-world examples of vehicles and machinery that use drive shafts?

Drive shafts are widely used in various vehicles and machinery to transmit power from the engine or power source to the wheels or driven components. Here are some real-world examples of vehicles and machinery that utilize drive shafts:

1. Automobiles:

Drive shafts are commonly found in automobiles, especially those with rear-wheel drive or four-wheel drive systems. In these vehicles, the drive shaft transfers power from the transmission or transfer case to the rear differential or front differential, respectively. This allows the engine’s power to be distributed to the wheels, propelling the vehicle forward.

2. Trucks and Commercial Vehicles:

Drive shafts are essential components in trucks and commercial vehicles. They are used to transfer power from the transmission or transfer case to the rear axle or multiple axles in the case of heavy-duty trucks. Drive shafts in commercial vehicles are designed to handle higher torque loads and are often larger and more robust than those used in passenger cars.

3. Construction and Earthmoving Equipment:

Various types of construction and earthmoving equipment, such as excavators, loaders, bulldozers, and graders, rely on drive shafts for power transmission. These machines typically have complex drivetrain systems that use drive shafts to transfer power from the engine to the wheels or tracks, enabling them to perform heavy-duty tasks on construction sites or in mining operations.

4. Agricultural Machinery:

Agricultural machinery, including tractors, combines, and harvesters, utilize drive shafts to transmit power from the engine to the wheels or driven components. Drive shafts in agricultural machinery are often subjected to demanding conditions and may have additional features such as telescopic sections to accommodate variable distances between components.

5. Industrial Machinery:

Industrial machinery, such as manufacturing equipment, generators, pumps, and compressors, often incorporate drive shafts in their power transmission systems. These drive shafts transfer power from electric motors, engines, or other power sources to various driven components, enabling the machinery to perform specific tasks in industrial settings.

6. Marine Vessels:

In marine applications, drive shafts are commonly used to transmit power from the engine to the propeller in boats, ships, and other watercraft. Marine drive shafts are typically longer and designed to withstand the unique challenges posed by water environments, including corrosion resistance and appropriate sealing mechanisms.

7. Recreational Vehicles (RVs) and Motorhomes:

RVs and motorhomes often employ drive shafts as part of their drivetrain systems. These drive shafts transfer power from the transmission to the rear axle, allowing the vehicle to move and providing propulsion. Drive shafts in RVs may have additional features such as dampers or vibration-reducing components to enhance comfort during travel.

8. Off-Road and Racing Vehicles:

Off-road vehicles, such as SUVs, trucks, and all-terrain vehicles (ATVs), as well as racing vehicles, frequently utilize drive shafts. These drive shafts are designed to withstand the rigors of off-road conditions or high-performance racing, transmitting power efficiently to the wheels and ensuring optimal traction and performance.

9. Railway Rolling Stock:

In railway systems, drive shafts are employed in locomotives and some types of rolling stock. They transfer power from the locomotive’s engine to the wheels or propulsion system, enabling the train to move along the tracks. Railway drive shafts are typically much longer and may have additional features to accommodate the articulated or flexible nature of some train configurations.

10. Wind Turbines:

Large-scale wind turbines used for generating electricity incorporate drive shafts in their power transmission systems. The drive shafts transfer rotational energy from the turbine’s blades to the generator, where it is converted into electrical power. Drive shafts in wind turbines are designed to handle the significant torque and rotational forces generated by the wind.

These examples demonstrate the broad range of vehicles and machinery that rely on drive shafts for efficient power transmission and propulsion. Drive shafts are essential components in various industries, enabling the transfer of power from the source to the driven components, ultimately facilitating movement, operation, or the performance of specific tasks.

What benefits do drive shafts offer for different types of vehicles and equipment?

Drive shafts offer several benefits for different types of vehicles and equipment. They play a crucial role in power transmission and contribute to the overall performance, efficiency, and functionality of various systems. Here’s a detailed explanation of the benefits that drive shafts provide:

1. Efficient Power Transmission:

Drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. By connecting the engine or motor to the driven system, drive shafts efficiently transfer rotational power, allowing vehicles and equipment to perform their intended functions. This efficient power transmission ensures that the power generated by the engine is effectively utilized, optimizing the overall performance and productivity of the system.

2. Versatility:

Drive shafts offer versatility in their applications. They are used in various types of vehicles, including cars, trucks, motorcycles, and off-road vehicles. Additionally, drive shafts are employed in a wide range of equipment and machinery, such as agricultural machinery, construction equipment, industrial machinery, and marine vessels. The ability to adapt to different types of vehicles and equipment makes drive shafts a versatile component for power transmission.

3. Torque Handling:

Drive shafts are designed to handle high levels of torque. Torque is the rotational force generated by the engine or power source. Drive shafts are engineered to efficiently transmit this torque without excessive twisting or bending. By effectively handling torque, drive shafts ensure that the power generated by the engine is reliably transferred to the wheels or driven components, enabling vehicles and equipment to overcome resistance, such as heavy loads or challenging terrains.

4. Flexibility and Compensation:

Drive shafts provide flexibility and compensation for angular movement and misalignment. In vehicles, drive shafts accommodate the movement of the suspension system, allowing the wheels to move up and down independently. This flexibility ensures a constant power transfer even when the vehicle encounters uneven terrain. Similarly, in machinery, drive shafts compensate for misalignment between the engine or motor and the driven components, ensuring smooth power transmission and preventing excessive stress on the drivetrain.

5. Weight Reduction:

Drive shafts contribute to weight reduction in vehicles and equipment. Compared to other forms of power transmission, such as belt drives or chain drives, drive shafts are typically lighter in weight. This reduction in weight helps improve fuel efficiency in vehicles and reduces the overall weight of equipment, leading to enhanced maneuverability and increased payload capacity. Additionally, lighter drive shafts contribute to a better power-to-weight ratio, resulting in improved performance and acceleration.

6. Durability and Longevity:

Drive shafts are designed to be durable and long-lasting. They are constructed using materials such as steel or aluminum, which offer high strength and resistance to wear and fatigue. Drive shafts undergo rigorous testing and quality control measures to ensure their reliability and longevity. Proper maintenance, including lubrication and regular inspections, further enhances their durability. The robust construction and long lifespan of drive shafts contribute to the overall reliability and cost-effectiveness of vehicles and equipment.

7. Safety:

Drive shafts incorporate safety features to protect operators and bystanders. In vehicles, drive shafts are often enclosed within a protective tube or housing, preventing contact with moving parts and reducing the risk of injury in the event of a failure. Similarly, in machinery, safety shields or guards are commonly installed around exposed drive shafts to minimize the potential hazards associated with rotating components. These safety measures ensure the well-being of individuals operating or working in proximity to vehicles and equipment.

In summary, drive shafts offer several benefits for different types of vehicles and equipment. They enable efficient power transmission, provide versatility in various applications, handle torque effectively, offer flexibility and compensation, contribute to weight reduction, ensure durability and longevity, and incorporate safety features. By providing these advantages, drive shafts enhance the performance, efficiency, reliability, and safety of vehicles and equipment across a wide range of industries.

editor by CX 2023-12-14

China supplier Alloy Steel Spur and Helical Gear Shaft for Cylindrical Gear Reducer drive shaft assembly parts

Product Description

Our Feature

1) In-house capability: OEM service as per customers’ requests, with in-house tooling design & fabricating

2) Professional engineering capability: On product design, optimization and performance analysis

3) Manufacturing capability range: DIN 3960 class 8 to 4, ISO 1328 class 8 to 4, AGMA 2000 class 10-15, JIS 1702-1703 class 0 to 2, etc.

4) Packing: Tailor-made packaging method according to customer’s requirement

5) Just-in-time delivery capability

Primary Competitive Advantages

1. Professional bull helical gear manufacturer

2. Experience in Cooperate with Fortune 500 Companies

3. Professional Engineering Capability

4. Stable Quality

5. Reasonable Price

6. Small Orders Accepted

7. Continuous Improvements

8. High Product Performance

9. Prompt Delivery

10. Professional Service

Our Main Product

1. Spur Gear

2. Planetary Gear

3. Metal Gears

4. Gear Wheel

5. Ring Gear

6. Gear Shaft

7. Helical Gear

8. Pinion Gear

9. Spline Shaft

Company Profile

1.21 years experience in high quality Gear Shaft’s production, sales and R&D

2. Our product, the Gear Shaft is certificated by ISO9001: 2008 and ISO14001: 2004.

3. CZPT has more than 50 patents in high quality Gear Shaft manufacturing and R&D fieles.

4. CZPT products are exported to America, Europe.

Q&A:

Service and quality information:

1. Q: Can you make as per custom drawing?

A: Yes, we can do that.

2. Q: If I don’t have drawing, what can you do for me?

A: If you don’t have drawing, but have the sample part, you may send us. We will check if we can make it or not.

3. Q: How do you make sure the quality of your products?

A: We will do a series of inspections, such as:

A. Raw material inspection (includes chemical and physical mechanical characters inspection),

B. Machining process dimensional inspection (includes: 1st pc inspection, self inspection, final inspection),

C. Heat treatment result inspection,

D. Gear tooth inspection (to know the achieved gear quality level),

E. Magnetic particle inspection (to know if there’s any cracks in the gear).

We will provide you the reports 1 set for each batch/ shipment.

| Capabilities of Gears/ Splines | ||||||

| Item | Internal Gears and Internal Splines | External Gears and External Splines | ||||

| Milled | Shaped | Ground | Hobbed | Milled | Ground | |

| Max O.D. | 2500 mm | |||||

| Min I.D.(mm) | 30 | 320 | 20 | |||

| Max Face Width(mm) | 500 | 1480 | ||||

| Max DP | 1 | 0.5 | 1 | 0.5 | ||

| Max Module(mm) | 26 | 45 | 26 | 45 | ||

| AGMA/ DIN Level | DIN Class 8 | DIN Class 4 | DIN Class 8 | DIN Class 4 | ||

| Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

| Max Helix Angle | ±22.5° | ±45° | ||||

Custom Made Parts Examples:

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated|

|

|---|

| Material: | 18Cr2Ni4WA |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Customization: |

Available

| Customized Request |

|---|

How to Replace the Drive Shaft

Several different functions in a vehicle are critical to its functioning, but the driveshaft is probably the part that needs to be understood the most. A damaged or damaged driveshaft can damage many other auto parts. This article will explain how this component works and some of the signs that it may need repair. This article is for the average person who wants to fix their car on their own but may not be familiar with mechanical repairs or even driveshaft mechanics. You can click the link below for more information.

Repair damaged driveshafts

If you own a car, you should know that the driveshaft is an integral part of the vehicle’s driveline. They ensure efficient transmission of power from the engine to the wheels and drive. However, if your driveshaft is damaged or cracked, your vehicle will not function properly. To keep your car safe and running at peak efficiency, you should have it repaired as soon as possible. Here are some simple steps to replace the drive shaft.

First, diagnose the cause of the drive shaft damage. If your car is making unusual noises, the driveshaft may be damaged. This is because worn bushings and bearings support the drive shaft. Therefore, the rotation of the drive shaft is affected. The noise will be squeaks, dings or rattles. Once the problem has been diagnosed, it is time to repair the damaged drive shaft.

Professionals can repair your driveshaft at relatively low cost. Costs vary depending on the type of drive shaft and its condition. Axle repairs can range from $300 to $1,000. Labor is usually only around $200. A simple repair can cost between $150 and $1700. You’ll save hundreds of dollars if you’re able to fix the problem yourself. You may need to spend a few more hours educating yourself about the problem before handing it over to a professional for proper diagnosis and repair.

The cost of repairing a damaged driveshaft varies by model and manufacturer. It can cost as much as $2,000 depending on parts and labor. While labor costs can vary, parts and labor are typically around $70. On average, a damaged driveshaft repair costs between $400 and $600. However, these parts can be more expensive than that. If you don’t want to spend money on unnecessarily expensive repairs, you may need to pay a little more.

Learn how drive shafts work

While a car engine may be one of the most complex components in your vehicle, the driveshaft has an equally important job. The driveshaft transmits the power of the engine to the wheels, turning the wheels and making the vehicle move. Driveshaft torque refers to the force associated with rotational motion. Drive shafts must be able to withstand extreme conditions or they may break. Driveshafts are not designed to bend, so understanding how they work is critical to the proper functioning of the vehicle.

The drive shaft includes many components. The CV connector is one of them. This is the last stop before the wheels spin. CV joints are also known as “doughnut” joints. The CV joint helps balance the load on the driveshaft, the final stop between the engine and the final drive assembly. Finally, the axle is a single rotating shaft that transmits power from the final drive assembly to the wheels.

Different types of drive shafts have different numbers of joints. They transmit torque from the engine to the wheels and must accommodate differences in length and angle. The drive shaft of a front-wheel drive vehicle usually includes a connecting shaft, an inner constant velocity joint and an outer fixed joint. They also have anti-lock system rings and torsional dampers to help them run smoothly. This guide will help you understand the basics of driveshafts and keep your car in good shape.

The CV joint is the heart of the driveshaft, it enables the wheels of the car to move at a constant speed. The connector also helps transmit power efficiently. You can learn more about CV joint driveshafts by looking at the top 3 driveshaft questions

The U-joint on the intermediate shaft may be worn or damaged. Small deviations in these joints can cause slight vibrations and wobble. Over time, these vibrations can wear out drivetrain components, including U-joints and differential seals. Additional wear on the center support bearing is also expected. If your driveshaft is leaking oil, the next step is to check your transmission.

The drive shaft is an important part of the car. They transmit power from the engine to the transmission. They also connect the axles and CV joints. When these components are in good condition, they transmit power to the wheels. If you find them loose or stuck, it can cause the vehicle to bounce. To ensure proper torque transfer, your car needs to stay on the road. While rough roads are normal, bumps and bumps are common.

Common signs of damaged driveshafts

If your vehicle vibrates heavily underneath, you may be dealing with a faulty propshaft. This issue limits your overall control of the vehicle and cannot be ignored. If you hear this noise frequently, the problem may be the cause and should be diagnosed as soon as possible. Here are some common symptoms of a damaged driveshaft. If you experience this noise while driving, you should have your vehicle inspected by a mechanic.

A clanging sound can also be one of the signs of a damaged driveshaft. A ding may be a sign of a faulty U-joint or center bearing. This can also be a symptom of worn center bearings. To keep your vehicle safe and functioning properly, it is best to have your driveshaft inspected by a certified mechanic. This can prevent serious damage to your car.

A worn drive shaft can cause difficulty turning, which can be a major safety issue. Fortunately, there are many ways to tell if your driveshaft needs service. The first thing you can do is check the u-joint itself. If it moves too much or too little in any direction, it probably means your driveshaft is faulty. Also, rust on the bearing cap seals may indicate a faulty drive shaft.

The next time your car rattles, it might be time for a mechanic to check it out. Whether your vehicle has a manual or automatic transmission, the driveshaft plays an important role in your vehicle’s performance. When one or both driveshafts fail, it can make the vehicle unsafe or impossible to drive. Therefore, you should have your car inspected by a mechanic as soon as possible to prevent further problems.

Your vehicle should also be regularly lubricated with grease and chain to prevent corrosion. This will prevent grease from escaping and causing dirt and grease to build up. Another common sign is a dirty driveshaft. Make sure your phone is free of debris and in good condition. Finally, make sure the driveshaft chain and cover are in place. In most cases, if you notice any of these common symptoms, your vehicle’s driveshaft should be replaced.

Other signs of a damaged driveshaft include uneven wheel rotation, difficulty turning the car, and increased drag when trying to turn. A worn U-joint also inhibits the ability of the steering wheel to turn, making it more difficult to turn. Another sign of a faulty driveshaft is the shuddering noise the car makes when accelerating. Vehicles with damaged driveshafts should be inspected as soon as possible to avoid costly repairs.

editor by CX 2023-05-15

in Srinagar India sales price shop near me near me shop factory supplier Power Reducer Transmission Auto Gear Custom Precision Gearbox Reduction for Stepper Motor Servo Motor manufacturer best Cost Custom Cheap wholesaler

With numerous years’ knowledge in this line, we will be dependable by our rewards in competitive cost, one-time supply, prompt reaction, on-hand engineering support and great right after-sales providers.In addition, all our creation procedures are in compliance with ISO9001 specifications. The group is concentrated on making all variety of standard roller chains and sprockets, gears & gearboxes, this sort of as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just sold its goods all more than china, but also offered a lot more than 65% merchandise to oversees, like Europe, The usa, South-east Asia, and it also has set up storage logistics in spots like Europe. Furthermore, all our generation methods are in compliance with ISO9002 specifications. We EPTize in developing and manufacture very engineered, custom made parts and assemblies. Our professional workers are EPTed in the direction of supplying clients with substantial quality products and excellent support .

Our primary products, metal EPTes for motors through powEPTmetallurgy processing.

A EPT is a EPT EPT system to make higher torque by minimizing the EPT speed or improve the EPT pace the other way. Planetary EPT consisting a few factors: EPTEPT, world EPT and ring EPT . A EPT EPT is a EPTwheel in a planetary EPT program, that rotates all around its possess aXiHu (West Lake) Dis.s and has other EPTs (world EPTs) that rotate about it. Much like the EPT and planets in our photo voltaic method. The sum of planetary EPTs in a EPT differs primarily based on the EPT ratio. Most planetary EPTes have from two to 5 world EPTs. When seeking at planetary EPTs, the power of the EPT is typically deterEPTd by the dimensions of the EPTEPT. Greater EPTEPTs will allow for greater torque values. The earth provider,Its objective is to hold up to EPTs of the identical measurement, which mesh with the EPTEPT.

Our EPT,LigEPT weight,little measurement, higher carrying ability, EPT services daily life .Clean operation, lower sounds, huge output torque, massive pace ratio, high effectiveness, EPT diversion, and multi-tooth meshing by powEPTmetallurgy method .

EPT ratio 3 to a thousand .

Tailored metal components specification

| Solution variety | Planetary EPT , EPT parts , velocity EPT |

| EPT | metal steel |

| Procedure | PowEPTmetallurgy , metal EPT molding |

| Therapy | plating ,sand blasting , PVD , coating |

| Tolerance | plusmn0.three% |

| Drawing structure | DWG ,IGS , STP |

| Shipping time | ten daEPTfor mass manufacturing |

PowEPTmetallurgy (PM) is a metal elements / factors fabrication way and created from metallic powders substance . The approach of powEPTmetallurgy (PM) is mixing fine powEPTmaterials , push them into a wanted condition or type compacting , and heating the compressed substance in a managed ambiance to bond the substance sintering .PM approach can keep away from , or drastically reduce the want to use steel removing processes,thus drastically minimizing generate losses in manufacture and oftern resulting in reduce EPTs .

The powEPTmetallurgy (PM) consist a few steps : powEPTblending,compaction and sintering .Common items incEPT EPTs , structural steel elements , bushings used for automobiles , EPTs and powEPTequipments .

Advantages of powEPTmetallurgy

EPT made by powEPTmetallurgy (PM) EPTly do not need to have even more ending , simply because produces very good surface finish.

Maintains near dimensional tolerances

Supplies materials which may be heat taken care of for increased toughness or improved use resistance .

There is much less wastage of raw substance , can be extremely affordable for mass creation .

Complicated designs areas can be created . Offers controlled porosity for self-lubrication or filtration.

Fits to substantial quantity parts productions specifications .

Custom metallic components

Workshop

China manufacturer & factory supplier for Superior in Chittagong Bangladesh quality RV Series Speed Reducer Reduction Gearboxes drive power transmission gear reducer with electric motor With high quality best price & service

ISO 9001 licensed company of precision roller chains. Kinds incorporate single and a number of strand, hollow pin, aspect bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless steel, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains.We will supply very best services and higher top quality items with all sincerity. a specialised provider of a full assortment of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

EPG Digital specializes in specific, high-efficiency generate options. We offer a broad assortment of built-in motors, brushless DC motors and stepper motors, as effectively as motor controllers and linear actuators that are primarily employed in automation systems, automatic laboratory products and healthcare products.

Overview

Swift Information

- Applicable Industries:

-

Creating Substance Retailers

- Gearing Arrangement:

-

Worm

- Output Torque:

-

4~2320Nm

- Input Pace:

-

.28~4.7rpm

- Output Velocity:

-

1400rpm(4pole)

- Location of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- Colour:

-

RAL9006(gray) OR RAL5010(blue)

- Label:

-

Consumer need

- The firm was qualified by ISO9001:2008 Good quality Management System. Material of housing:

-

Aluminum&Forged Iron

In our business we are aware of the value of the users’ security. Which is why our PTO’s are created according to lawful restrictions and European directives and bear the CE indication. A essential aspect for safety assurance is the accession in the products’ development section. By all means, the users’ expertise about the proper use of a PTO drive shaft is vital. This signifies, that each and every users’ obligation is to go through and adhere to the security instructions.

- Enter Flange:

-

IEC flange for mounting motor

- Customization:

-

Acceptable

- Good quality Handle Program:

-

ISO9001:2008

Source Capability

- Offer Ability:

- 20000 Set/Sets for every Thirty day period

Packaging & Supply

- Packaging Specifics

- Carton + Picket Case

- Port

- Shanghai/Ningbo port

-

Guide Time

: -

Amount(Containers) 1 – 1 >1 Est. Time(times) 20 To be negotiated

On-line Customization

Specification

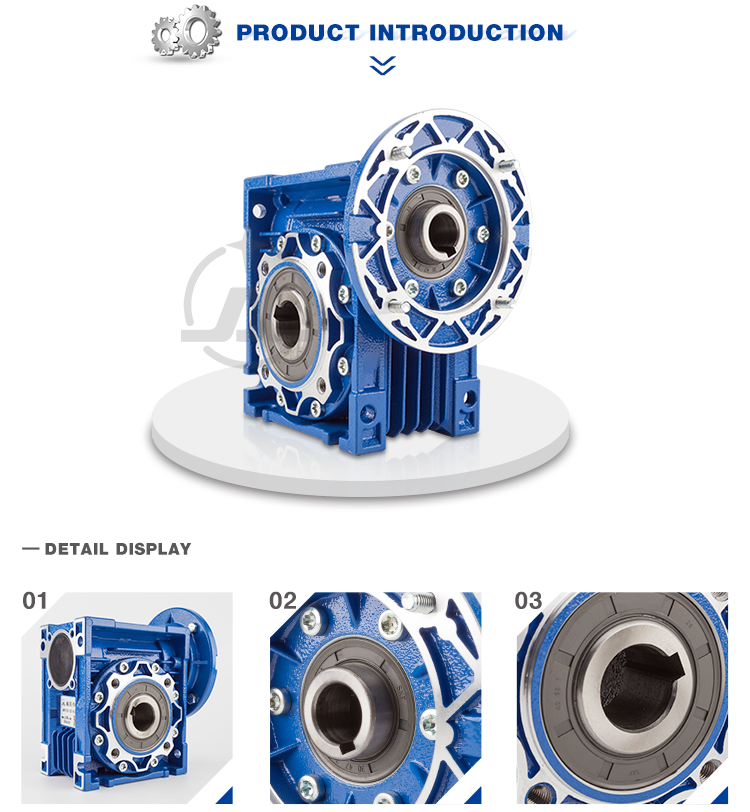

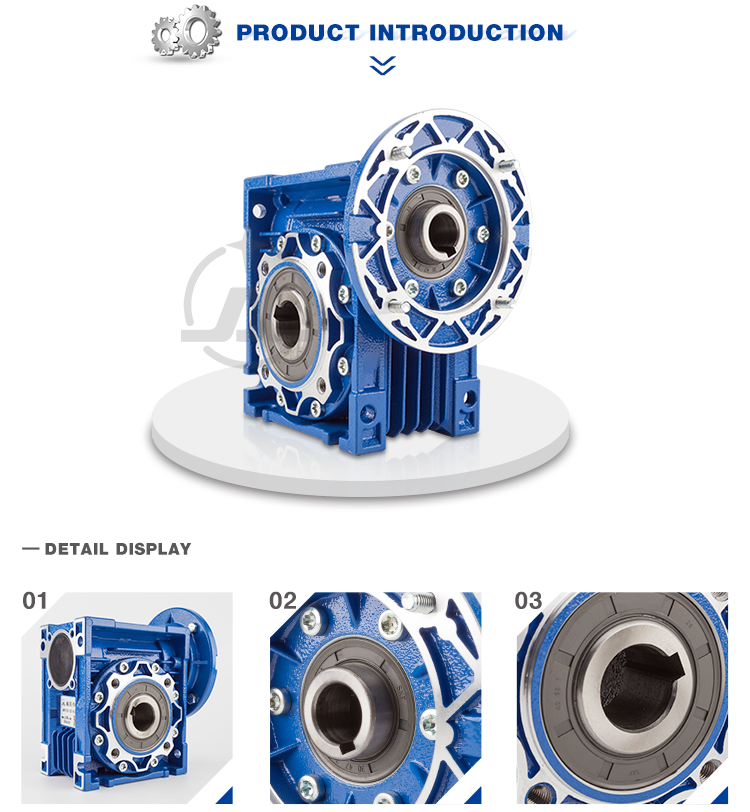

Outstanding top quality RV Collection Pace Reducer Reduction Gearboxes push energy transmission equipment reducer with electric motor

Items Traits

1. Mad of high-top quality aluminum alloy,light excess weight and non-rusting

2. Big output torque

three. Sleek in operating and minimal in sounds,can function lengthy time in dreadful circumstances.

four. Higher in radiating effectiveness.

5. Good-seeking in look,sturdy in support life and small in quantity.

6. Suitable for omnibearing installation.

|

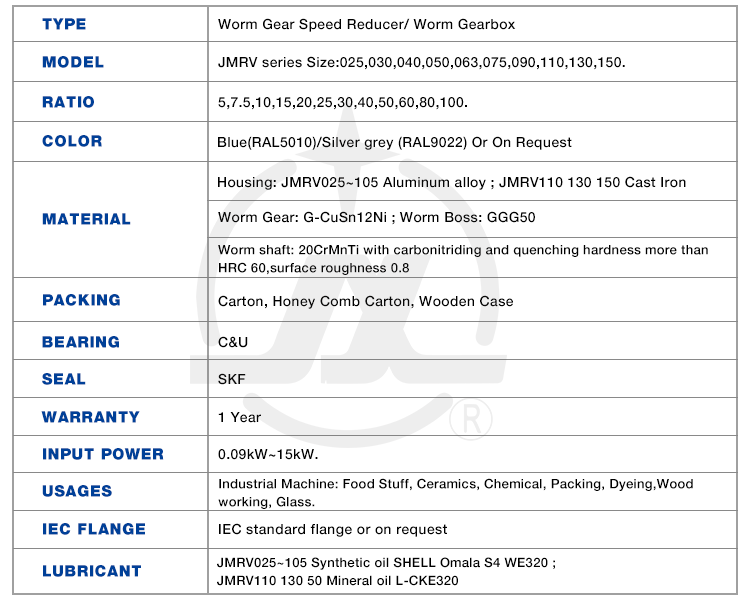

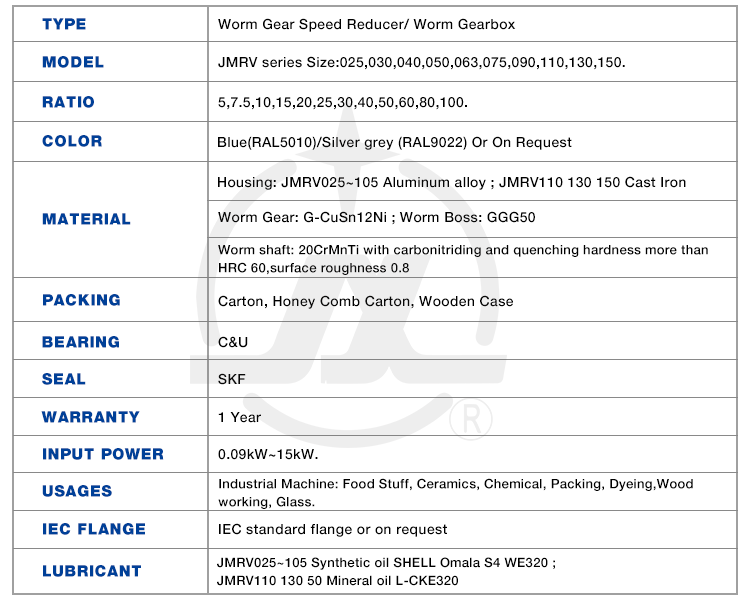

Variety: |

Worm Equipment Speed Reducer/ Gearbox |

|

Model No.: |

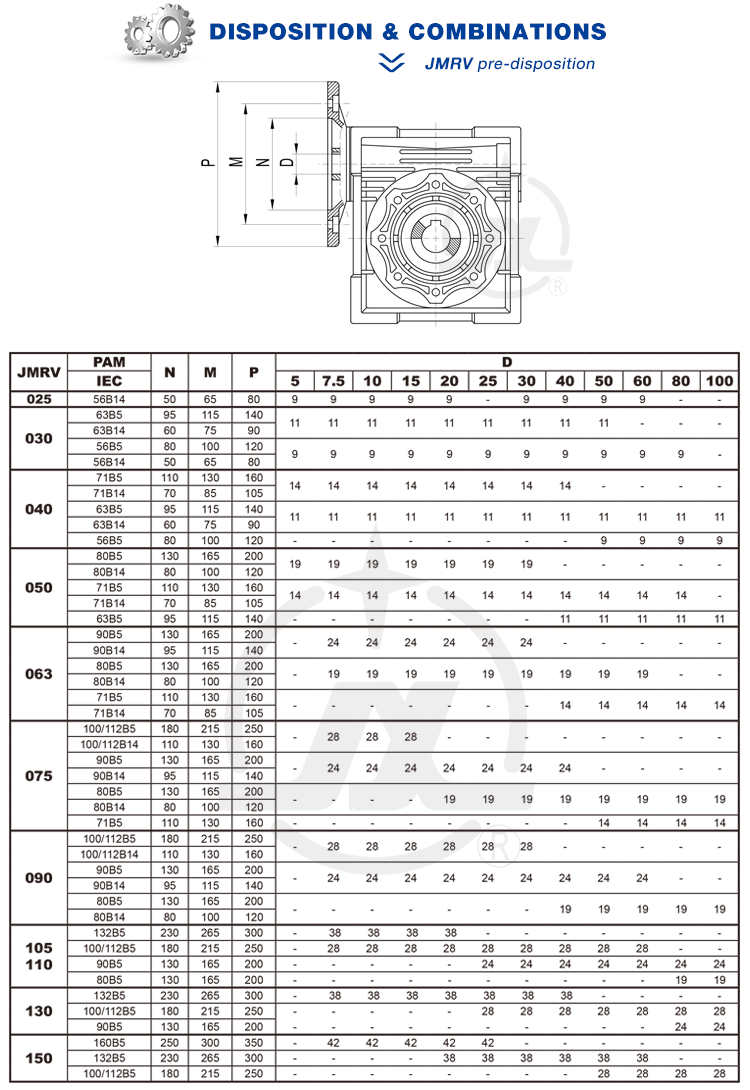

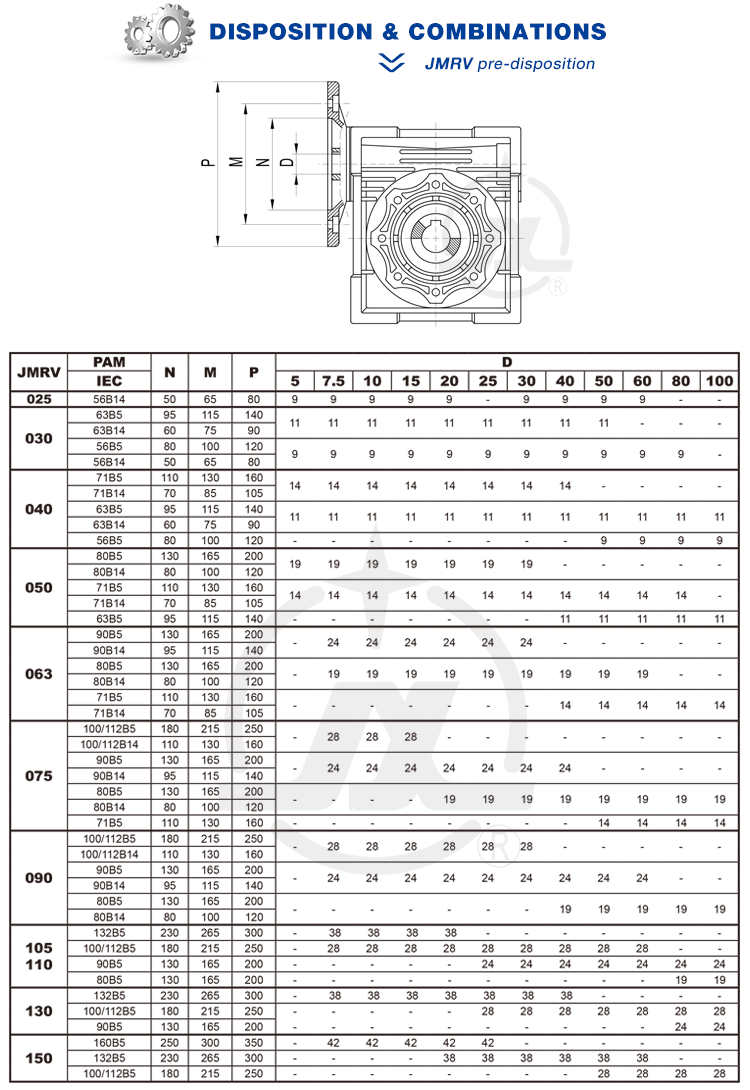

NMRV025, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

|

Ratio: |

five,7.5,10,15,20,25,30,forty,50,sixty,80,a hundred |

|

Coloration: |

Blue(Ral5010)/Silver Gray (RAL9006) Or On Customer Request |

|

Material: |

Housing: Measurement twenty five-110 Is Aluminum Alloy, Size 110-one hundred fifty Is Forged-Iron |

|

Worm Wheel: ZCuSn10Pb1 |

|

|

Worm:20Cr |

|

|

Pinion:Tin Bronze |

|

|

Output Shaft: Steel-forty five# |

|

|

Usages: |

Industrial Equipment: Foods Stuff, Ceramics, Chemical, Packing, Dyeing,Wood operating, Glass. |

|

IEC Flange: |

IEC Common Flange Or On Buyer Ask for |

Company data

Top quality handle

Packing

Shipping

FAQ

Q1: What details must I explain to you to verify the item?

A: Design/Dimension, Transmission Ratio, Shaft instructions & Get quantity.

Q2: What can i do if I do not know which one I need?

A: Will not fret, Send as a lot details as you can, our crew will aid you uncover the proper 1 you are looking for.

Q3:What is your merchandise guarantee period of time?

A:We offer you one 12 months warranty because the vessel departure day remaining China.

If you have yet another query, pls truly feel free to get in touch with us as underneath:

Get in touch with us

China manufacturer & factory supplier for foot-mounted in Agartala India parallel shaft helical gear reducer With high quality best price & service

EPG key manufacturer and provider of ball bearings and energy transmission equipment. Considering that it’s commencing in 1992, EPG has grown into one particular of the leading suppliers in the business. Important variables that have contributed to our growth is our determination to the fundamentals of revolutionary design, aggressive pricing, extraordinary client support, and item availability.ensures the security and regularity of the crucial operate of elements.

Overview

Swift Specifics

- Applicable Industries:

-

Production Plant

- Rated Power:

-

.12~200kw

- Design Variety:

-

F

- Bearing:

-

NSK

- Certificate:

-

A worm equipment system consists of a worm and worm wheel. The worm resembles a screw, which fulfills with a worm wheel, as proven in the picture. When rotational energy is used to the worm, it rotates from the wheel and transfers energy to the worm wheel. The system is made so that the worm can very easily flip the equipment, but the equipment can not turn the worm. In some designs, the friction in between the equipment and worm holds the worm in spot. This function can be really helpful in some applications.

ISO9001

- Input Type:

-

IEC Flange

- Product title:

-

foot-mounted parallel shaft helical equipment reducer

- Mounting Place:

-

Foot Mounted. Flange Mounted

Our patented coupling mechanism C Line is the consequence of our information and improvement. It permits easy coupling and uncoupling of the PTO generate shaft. The protect offers the user more convenience due to the fact of its ergonomically and compact kind. The users’ protection is certain, because he can not get entangled in protruding components of the yoke. There is also much less grime present at dealing with and there are much less troubles linked with it.

- Colour:

-

Client Ask for

Source Ability

- Source Capability:

- 3000 Piece/Pieces per Thirty day period

Packaging & Shipping

- Packaging Details

- About shipping and delivery:Ocean transport and air freight.”>About packing:We normally use the fumigation wooden circumstance packing,also can be customized in accordance to consumer provider request.

About transport:Ocean shipping and delivery and air freight.

- Port

- Ningbo

-

Direct Time

: -

Amount(Containers) 1 – 9999 >9999 Est. Time(times) twelve To be negotiated

On-line Customization

Merchandise Software

Software Sector Printing machinery, paper business equipment, bag-generating machinery, paper-producing machinery, wire and cable equipment, coil machinery, wire machinery, strapping bag machinery, textile equipment, weaving-dimensional machinery, woodworking machinery, examination equipment, analog load use, the varieties of mechanical precision rigidity managing, standard industrial equipment, other general industrial equipment

Machine Elements

Output Torque: 200 – 18000 N.m

Rated Electrical power: 0.twelve-200kw

KC collection helical-bevel gearbox is the combination transmission structure of helical gears and spiral bevel gears, with massive transmission torque and continual running

Tiny vibration and reduced sounds, with huge transmission ratio, the transmission performance is considerably larger than SC collection.

The productsIt is our aim to supply a extensive assortment of good quality merchandise at affordable costs, offer the ideal provider for buyers content and add to our continued improvement. have been mainly employed in petrochemical machinery, metallurgy, printing and packaging machinery, ceramic equipment, mine and design equipment, stage equipment, and many others.

Pre-Sales Provider

* Inquiry and consulting help.

* Sample testing help.

* See our Manufacturing unit.

Right after-Product sales Services

* Education how to instal the equipment, coaching how to use the machine.

* Engineers accessible to service equipment abroad.

Packaging | |

Shipping | by sea, by air, or categorical shipping and delivery,this sort of as DHL, FEDEX, UPS… |

Weight | In accordance to the production |

Packaging Information | The regular bundle is wood box(Measurement: L*W*H). If export to european nations,the picket box will be fumigated.If container is way too tigher,we will use pe film for packing or pack it according to buyers particular request. |

1, Q:what’s your MOQ for every collection gearbox ?

A: 1unit is ok for various sorts gearbox motor .

two, Q: What about your guarantee for your gear reducer with motor ?

A: One 12 months ,but other than male-made destroyed

3, Q: How about your payment terms ?

A: TT, total payment t by T/T in advance

4, Q: how about your packing ?

A: Little dimension:normal export packing(carton and plled).

Large measurement : Fumigated wood carton or non-wood packing content carton.

five, Q: What information must be offered, if I get gearbox from you ?

A: Rated energy, Gearbox ratio, enter velocity,Mounting position,More information, greater!

Thanks for your time to see previously mentioned data, if you have any much more unclear you should get in touch with us straight by e-mail or phone.

A few-stage foot-mounted helical gear reducer

91.8% Reaction Rate

Helical bevel equipment reducer

91.8% Reaction Price

Helical- worm gear reducer

91.8% Reaction Rate

Best Custom made in China – replacement parts – PTO shaft manufacturer & factory Tractor pto gear reducer Mounted Farm Implements 1lyq Serious Disc Plough with ce certificate top quality low price

We – EPG Team the greatest agricultural gearbox and pto manufacturing facility in China with 5 various branches. For much more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

pto shaft classes EPG e30 driveshaft specializing hydraulic pump to pto adapter in 2005 jeep liberty rear push shaft the lengthier drive shaft for lifted trucks manufacture tri oval pto shaft of pto protect rotocultivator pto plastic protect ploughshares 2002 ford explorer entrance push shaft and pto shafts slide other non-standardized farm machinery chopping resources. The company was licensed by ISO9001:2008 Quality Management System. Product Description:

This agricultural tractor disc plow for sale is designed specifically for paddy field. When it works inpaddy-field it turns up soil to make soil upturned, in lines and level. Wheat and rice stubble and Chinesemilk vetch are turned down and buried in the field they are easy to rotten and increasing the organicfertilizer of the filed. It also has advantages of saving labor, working efficiently and low cost etc.

| Sort | 1LYQ-320 | 1LYQ-420 | 1LYQ-520 | 1LYQ-522 | 1LYQ-622 | 1LYQ-722 | 1LYQ-822 | 1LYQ-922 | 1LYQ-722 | 1LYQ-822 | 1LYQ-922 | 1LYQ-822 | 1LYQ-922 | 1LYQ-1571 | 1LYQ-825 | 1LYQ-925 | 1LYQ-1571 |

| Working width (mm) | 600 | 800 | 1000 | 1100 | 1320 | 1540 | 1760 | 1980 | 1540 | 1760 | 1980 | 1760 | 1980 | 2200 | 2000 | 2250 | 2500 |

| Doing work depth (mm) | 12-20 | fourteen-22 | |||||||||||||||

| Output pace(rpm/min) | 540-740 | ||||||||||||||||

| Dia. of disc (mm) | 510 | 510 | 510 | 560 | 610 | ||||||||||||

| Excess weight (kg) | 230 | 250 | 280 | 330 | 360 | 390 | 420 | 460 | 600 | 650 | seven hundred | 700 | 750 | 800 | 850 | 900 | 950 |

| Linkage | three stage mounted with PTO shaft | ||||||||||||||||

| Matched energy (hp) | 20-thirty | twenty five-thirty | twenty five-35 | 35-45 | 40-55 | 55-65 | sixty five-75 | 70-eighty | 80-100 | eighty-one hundred | 90-a hundred and twenty | 90-a hundred and twenty | 100-a hundred and twenty | a hundred-one hundred twenty | 110-150 | ||

| Working pace(km/h) | 3-four | ||||||||||||||||

| Body sort | Circular beam | ||||||||||||||||

Detailed Photograph&Packing:

Our Company:

With more than sixteen many years of production expertise, we have produced full tillage machinery, pl EPT machinery and harvesting machinery, such as tractors, disc harrows, disc plows, mowers, rotary tillers, deep plowing machines and far more, showcasing comprehensive specifications, reputable top quality and outstanding efficiency. Our goods are not only offering properly during our country, but also exported to clientele in Europe, Africa, the Center East, Southe EPT Asia and other nations and regions. Our company integrity and quality have been extremely acknowledged. More than the a long time, we have been awarded “Degree A Tax Paying Company” and “Amount AA Lender Credit Organization”.

| Company type | Manufacturer |

| Place | Shiliwang Industrial Zone of HangZhou, ZheJiang ,China |

| Year Proven | 2003 |

| Occupied location | 50 Acres |

| Business certification | CE, ISO9001, SGS |

| Principal product | disc harrow, disc plough, trailer, increase sprayer , rotary tillers, potato planter ,plowing blade, plough blade, soil-loosening shovel and so on. With very good quality and excellent efficiency, our products are annually exported to international locations around the globe, and we have gained absolute have confidence in from our customers. |

Packing:

Following-product sales Service:

twelve months guarantee period of the main areas. We will ship the promise components jointly with the equipment in your up coming get or we can send them by air convey if you need it urgently.

FAQ:

one. Q: Full price tag list for these goods

A: Remember to comprehend we have a very broad merchandise selection, typically we don’t offer entire products price checklist. Kindly remember to specify the product model, so we can estimate you appropriately.

2. Q: Company terms

A: Shipment time: 25-40 days after your payment

Shipment: By sea

Loading port: HangZhou port, China

Vacation spot port: …To be recommended

Payment: T/T, L/C

Warranty: 1 year

3. Q: How can I get from you?

A: Remember to send us your enquiry listing, and we will reply you within two functioning days.

4. Q: If the figure I look for are not in your catalogue, what ought to I do?

A: We can build it according to your drawing or sample.

five. Q: W EPT pick EPT for cooperation?

A: Evaluating with our competition, we have considerably more positive aspects as follows:

1). A lot more than 30 years experience in manufacturing farming machines.

2). More Expert Income folks to promise greater and expert service.

3). Broader merchandise assortment of agri equipment for your choice.

4). Far more recently created items to highlight you among your opponents and help you avoid price opposition.

five). Much better capability for mass manufacturing and bulk cargo.

6). Better high quality to ensure greater Credit score.

seven). More rapidly shipping and delivery time: Only 7 times.

eight). Considerably stricter top quality examine procedures ahead of cargo.

9). A lot more thoughtful right after-sales services.

10). Far more famous brand name: HONGRI brand and “CE” certificate.

eleven). Reduced fix charge and reduce bad-evaluation rate.

twelve). We have American branch office to demonstrate our main items there, which helps us to fasten the speed of responding to our clients’ demands.

You should inform us much more about your wants,we are all looking ahead to listening to from you.

China manufacturer & factory supplier for Factory in Bergamo Italy heavy duty ZQ 350 horizontal cylindrical gear reducer gearbox transmission accessories With high quality best price & service

ISO 9001 qualified maker of precision roller chains. Types contain one and several strand, hollow pin, side bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless steel, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains.Ever-Power Group CO., LTD. IS Professional IN Producing ALL Types OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Speed REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Automobile GEARBOXES, PTO Drive SHAFTS, Specific REDUCER & Related Gear Parts AND OTHER Connected Goods, SPROCKETS, HYDRAULIC Technique, VACCUM PUMPS, FLUID COUPLING, Equipment RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARThe firm was licensed by ISO9001:2008 High quality Management Program.S Lower BACKLASH WORM REDUCERS AND pto shaft, agricultural gearboxes SO ON.

Overview

Swift Details

- Relevant Industries:

-

Producing Plant

- Model Identify:

-

OEM

- Merchandise NO:

-

SYF

- Content of Housing:

-

Cast Iron HT200

- Coloration:

-

Consumer Requirement

- Ratio:

-

eight.23-48.fifty seven

- Certification:

-

ISO9001

- Fat:

-

260kg

- Equipment material:

-

forty five# Steel

- All Product:

-

250-1000

- Enter pace:

-

650-1500rpm

Packaging & Delivery

-

Guide Time

: -

Amount(Items) one – one 2 – five >5 Est. Time(days) 3 10 To be negotiated

On the internet Customization

Item Description

ZQ JZQ Sequence Cylindrical Equipment Reducer

ZQ JZQ Cylindrical gear reducer, two-phase cylindrical equipment transmission. It is broadly employed in lifting and transportation equipment, mining machinery and standard chemical market. Its functioning temperature is – 40C +45C, input velocity is not higher than 1500 rpm, gear generate circumferential velocity is not more than fourteen m/s, and it can operate in both instructions.

The subject of cylindrical equipment reducer is widely utilized in metallurgical products, mining gear, automation tools, food machinery, packaging equipment, tobacco products and many others..

|

Solution Identify |

ZQ JZQ Sequence Cylindrical Gear Reducer |

|

Tooth area hardness |

Gentle tooth surface |

|

Installation kind |

Horizontal installation |

|

Structure fAs an personnel owned company, we are fully commited to exceeding our customers’ anticipations via every single stage of the equipment producing process. For customized worms and worm gears made to your actual specifications, you can come to feel assured turning to Equipment Motions.orm |

ThreeOur patented coupling system C Line is the consequence of our information and advancement. It permits effortless coupling and uncoupling of the PTO travel shaft. The protect offers the user more ease and comfort because of its ergonomically and compact form. The users’ stability is assured, because he can’t get entangled in protruding components of the yoke. There is also less dust current at managing and there are fewer troubles linked with it.-ring format |

|

Merchandise traits |

Higher quality shell, resilient, stable use |

|

Scope of use |

Utilized to general machinery and tools with no particular specifications, this sort of as agricultural machinery, foodstuff machinery, enthusiasts, pumps, machine resources, mixers, and many others. |

|

Matters needing interest |

The motor need to keep its floor clean during procedure. Motor recent shall not exceed 10% of rated existing. |

|

Good quality Upgrade |

Manufacture with the most current complex specifications and update merchandise |

|

Strong and resilient |

Created of high good quality material, durable |

|

Very good applicability of the total equipment |

It can be put in in numerous ways with enter and output modes. |

|

Substantial dependability |

Heavy fat, secure operation and long provider daily life |

|

Operating lower noise |

In the approach of operation, the sound is lower, offering you a greater experience and use. |

ZQ JZQ Collection Cylindrical Gear Reducer Shape, Shaft Stop and Installation Proportions

Substantial Top quality Shell, Thickened and Resilient

Thickened Equipment, Fantastic Bearing, Substantial Top quality Carbon Metal

Compact Composition, Steady Procedure and Lower Noise

Our Firm

HANGZHOU At any time-Energy Group, One particular OF THE Largest GEARBOX Manufacturing unit IN CHINA, ELECTROMECHANICAL Equipment Offer STATION

Our business is positioned in the metropolis of HangZhou, ZheJiang Province of China.

We handle the goods of power transmission, our strains mainly include sequence items in speed reducers, gearboxes , related electricial motors and other electrical power transmission accessories. Dependent on the flexible functions, our products can be used in a lot of fields: equipment of waste h2o treatment, dredgers, chemical business, cranes, metallic working mills, conveyors, paper industry, cement sector, cableways and so on.With the exceptional quality and sensible price tag , our items enjoy a good track record from customers and the friends all over the planet.

Additionally, the R&D investment decision are every year escalating for the objective of far better assembly the new calls for of our buyers and adapting the new inclination of the market.

Depending on the rules of honestly working and mutual benefit, We sincerely search forward to cooperating with you.

Software spot

Certifications

Revenue territory

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to make sure the integrity of merchandise appearance, we will choose cartons, wooden pallets and wood pallets according to customer needs.

●Delivery time: Every single reducer is made and examined in accordance with rigorous and fixed methods to ensure that the quality is correct ahead of leaving the factory and shipping on time.

●Transportation manner: We will choose the most ideal method of transportation for our customers in accordance to the fat and measurement of the products. We can also choose the manner of transportation in accordance to the needs of our clients.

●Receiving and soon after-sales service: After receiving the items, please check out whether or not they are in excellent problem. We will provide consumers with perfect after-income services.

FAQ

Q1: Are you a buying and selling company or a producer ?

A: We are a producer in ZheJiang Province, China. Our firm owns the capacity of production, processing,creating and R&D. We welcome your go to.

Q2: How we choose versions and technical specs?

A: According to the distinct particulars of the demands from the portion of enquiry, we will recommend the products’ versions on synthesizing the factors of subject of products use, electricity, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our costs are constantly aggressive. If the consumer can area a big order, we absolutely will allow low cost.

Q4: How lengthy should I wait for the feedback after I send out the enquiry?

A4: We will reply the enquiries without any hold off, twelve several hours at most.

Q5: What is your item warranty interval?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes getting utilized?

A: Our gearboxes are extensively used to metallurgical equipment, mining products, automation equipment, food equipment, packaging products, tobacco gear and so on.

China manufacturer & factory supplier for X B in Bauchi Nigeria series vertical cyclo gear reducer coaxial planetary reducer cyclo gear motor electric motor speed reducer With high quality best price & service

Our big stock levels on zinc plated, sound steel shaft collars guarantee prompt satisfaction of any measurement prerequisite. Unplated, black-oxide and stainless steel reliable collars are conveniently accessible. Black-oxide metal clamp variety collars are in the same way stocked for unbeatable support. Mounted bearing and linear bearing orders are routinely transported inside 24 hrs and our switch-around time on lower-to-duration linear shafting will exceed your anticipations.In this way, our products have continued to acquire marketplace acceptance and customers pleasure over the previous few years.

Overview

Fast Specifics

- Relevant Industries:

-

Resorts, Creating Content Retailers, Manufacturing Plant, Equipment Restore Shops, Foods & Beverage Manufacturing unit, Farms, Energy & Mining, Food & Beverage Outlets, Construction works

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- GOur merchandise is well-known exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The us, Thailand, Pakistan, Indonesia, far more than 60 nations around the world and regions.earing Arrangement:

-

Cycloidal

- Output Torque:

-

two.6-20000N.m

- Input Speed:

-

750-3000rpm

- Output Pace:

-

eleven-280rpm

In our company we are conscious of the value of the users’ safety. Which is why our PTO’s are made in accordance to legal rules and European directives and bear the CE indicator. A essential aspect for security assurance is the accession in the products’ advancement period. By all means, the users’ understanding about the proper use of a PTO generate shaft is crucial. This implies, that each and every users’ obligation is to read and follow the protection directions.

- Ratio:

-

6-51133

- Substance:

-

Solid Iron

- Content of output:

-

large-power alloy metal

- Rotation Path:

-

Regular or Reverse

- Shade:

-

Buyer Requests

- Materials of gear:

-

20CrMoTi

- Good quality Control Program:

-

GB/T19001- 2008

Source Ability

- Provide Capacity:

- 50000 Established/Sets for each Calendar year

Packaging & Supply

- Packaging Particulars

- Stanard wooden circumstance, or wood pallet

- Port

- SHANGHAI PORT / NINGBO PORT

Online Customization

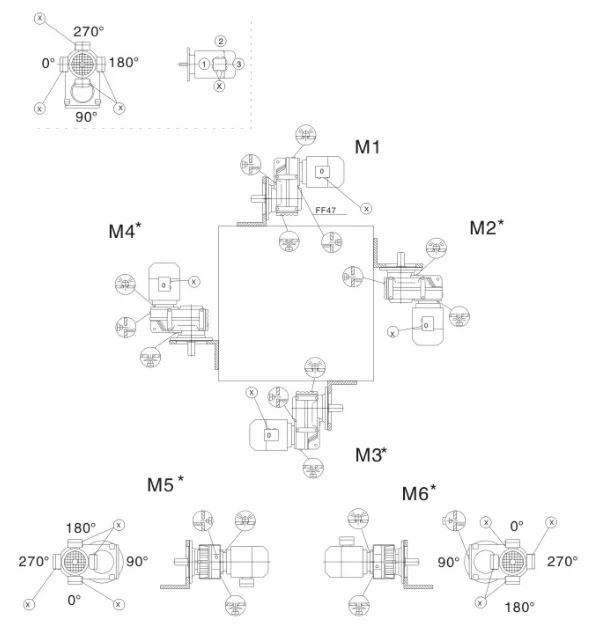

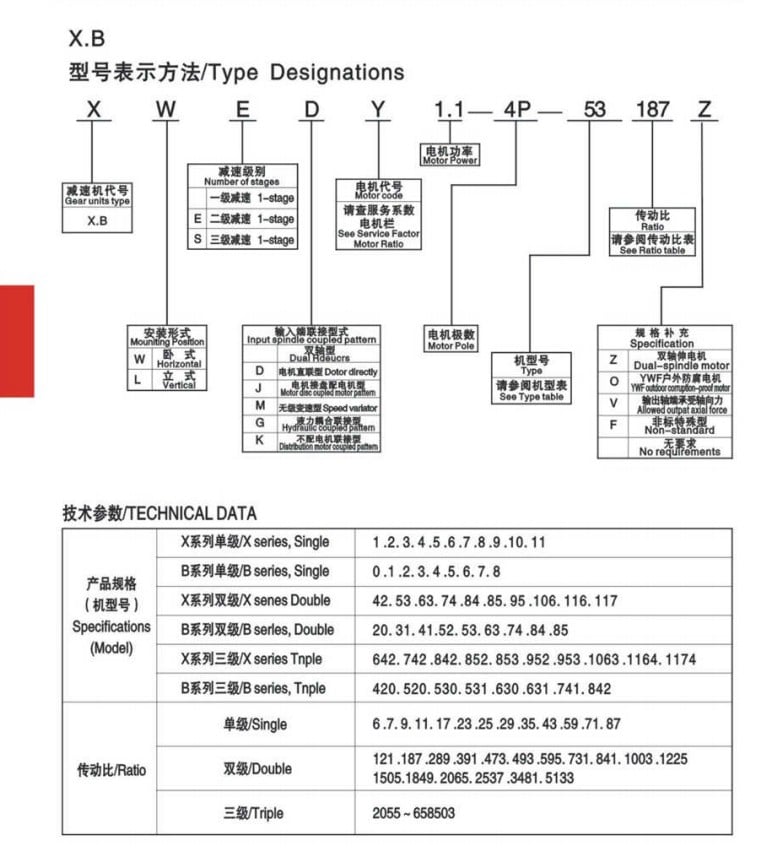

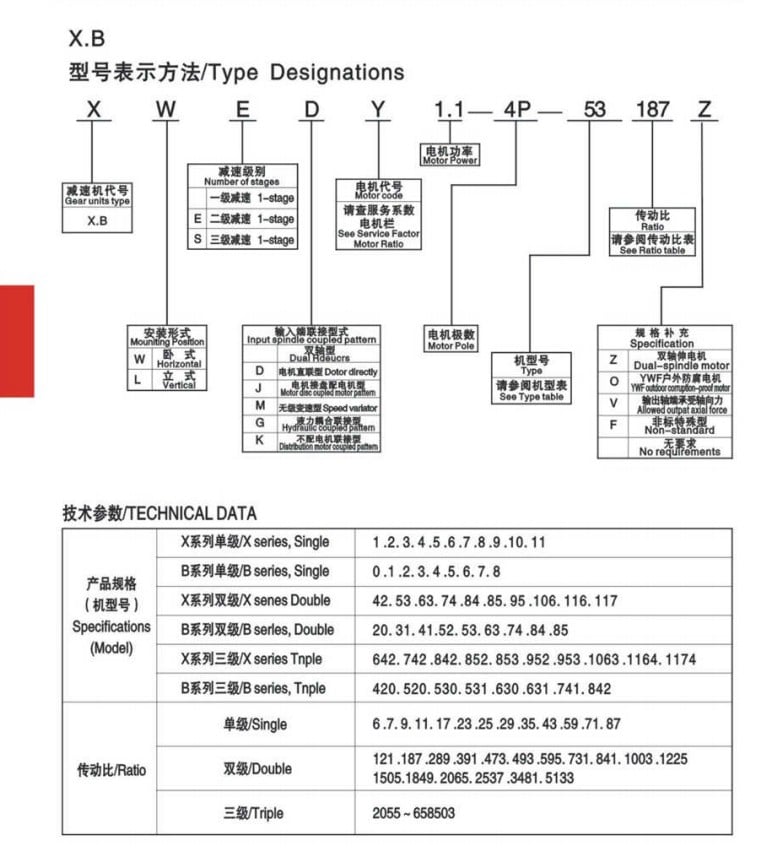

X/B sequence vertical cyclo gear reducer coaxial planetary reducer cyclo equipment motor electric powered motor velocity reducer

Merchandise Description

Rapid Details:

Variety: XB collection Cycloidal Pin Wheel Velocity Reducer Enter Speed: 1000-1500rmp Output Speed: .3-280rpm

Certification: ISO9001 CE Ex Electricity:.09-132KW Warranty: 1Years

|

Solution Identify |

X/B Sequence vertical type cycloidal reducer |

|

The Gear Material |

GCR15 |

|

The situation Materials |

Solid Iron |

|

Coloration |

Blue,Eco-friendly, or Customized |

|

HS Code |

84834090 |

|

Product |

XLD3 |

|

Supply time |

ten-12days |

|

Brand |

TIANGOU |

Business Info

Certifications

Expo& Buyers

Our Services

Packaging & Delivery

FAQ

: Are you buying and selling firm or company ?

A: We are factory.

Q: How extended is your shipping and delivery time?

A: Usually it is 5-ten days if the goods are in stock. or it is fifteen-twenty days if the goods are not in stock, iSeries B Right Angle Worm GearEPG Travel Sequence B Appropriate Angle Worm Geart is according to amount.

Q: Do you provide samples ? is it free or added ?

A: Indeed, we could offer the sample for cost-free charge but do not shell out the price of freight.

Q: What is your conditions of payment ?

A: Payment=1000USD, thirty% T/T in progress ,balance before shippment.

If you have one more query, pls feel free to make contact with us as under:

Get in touch with us

Rx sales made in China replacement parts Rxf77 in Leon de los Aldamas Mexico Parallel Shaft Helical Gear Reducer with top quality

We – EPG Group the greatest gearbox & motors , couplings and gears manufacturing unit in China with 5 different branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

Overview

———————————————————————————————————————————————————————————————————————————————–

Swift Particulars

Gearing Arrangement: Helical Model Name: EED

Input Pace: 1400 rpm Output Pace: 4.8 rpm to 1075 rpm

Rated Electrical power: .twelve ~ 160KW Equipment Ratio: 2.sixty four-251.twenty five

Colour: Blue/Silver or on request Origin: ZHangZhoug, China (Mainland)

Warranty: 1 Year Application: ept

———————————————————————————————————————————————————————————————————————————————–

Source Capability

Supply Capability: 20000 Piece/Items for each Thirty day period

Further Services: OEM is welcome

QC System: ISO9001:2008

———————————————————————————————————————————————————————————————————————————————–

Packaging & Shipping and delivery

Package deal: Wood box/Paper carton

Port: HangZhou/ZheJiang or on request

———————————————————————————————————————————————————————————————————————————————–

About ept given that 1984

HangZhou Melchizedek Import & Export Co., Ltd. is a leader manufactur in mechanism area and punching/stamp

ing discipline since 1984. Our primary product, NMRV worm equipment speed reducer and series helical gearbox, XDR,

XDF, XDK, XDShave achieved the advanced technique index of the congeneric European and Janpanese produc

ts, We provide standard gears, sprockets, chains, pulleys, couplings, bushes and so on. We also can take orders

of non-common merchandise, these kinds of as gears, shafts, punching components ect, in accordance to customers’ Drawings or sam-

ples.

Our organization has full set of products which includes CNC, lathes, milling equipment, equipment hobbing machine, g-

ear grinding device, gear honing machine, equipment shaping equipment, worm grinder, grinding equipment, drilling m-

achines, boringmachines, planer, drawing benches, punches, hydraulic presses, plate shearing devices and s-

o on. We have sophisticated testing equipments also.

Our company has recognized favorable cooperation associations with sub-suppliers involving casting, uncooked mat-

erial, heat therapy, area finishing and so on.

The use of original gear manufacturer’s (OEM) part numbers or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating product use and compatibility. Our company and the listed replacement areas contained herein are not sponsored, authorized, or manufactured by the OEM.

Best China manufacturer & factory Good in Yekaterinburg Russian Federation price mini 1 20 ratio worm gear reducer With high quality best price

Our product range also covers locking assemblies (clamping elements/locking device), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

-

Gearing Arrangement:

PTO shaft connectors on tractors are not standardized which can lead to complications when connecting the PTO shaft. For example, some older tractor models have the connection flange closer to the tractor itself making it difficult to connect and lead to a potential safety hazard. -

worm

- Output Torque:

-

15~1700Nm

- Input Speed:

-

500~2800/miEPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools. n

- Output Speed:

-

5~560/min

- Brand Name:

-

OEM

- Product name:

-

1 20 ratio worm gear reducer

- Application:

-

Food Stuff, Ceramics, Chemical, Packing, Dyeing,Wood working, Glass.

- Color:

-

Blue(RAL5010)/Silver grey (RAL9022) Or On Request

- Ratio:

-

5,7.5,10,15,20,25,30,40,50,60,80,100.

- Warranty:

-

1 Year

Supply Ability

- Supply Ability:

- 36000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Transparent box packaging, or color box packaging, it also can be customized.

Breathers or vent plugs eliminate internal pressure buildup, but often provide a leakage path for lubricant. Bubbles of oil form over the air passageway and eventually percolate to the outside.

- Port

- Ningbo/Shanghai

Online Customization

Good price mini 1 20 ratio worm gear reducer

Q1.How to choose a 1 20 ratio worm gear reducer which meets our requirement?

A1: You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of output torque, output speed and motor parameter etc.

Q2.How is your price? Can you offer any discount?

A2: We will give the best price we can base on your needs and the quantities.

Q3.Do you offer any visiting?

A3: Yes! We sincerely invite you to visit us! We can pick you from airport, railway station and so on.

Also, we can arrange housing for you. Please let us know in advanced.

Q4.When is the best time to contact you?

A4: You can contact us by email any time, we will reply you as soon as possible.

Q5.How long will it take for the lead time?

A5: For our standard model, please refer to the different product pages to check the lead time.

For the OEM/ODM products, please contact us for further information.