Product Description

Machining Capability

Our Gear, Pinion Shaft, Ring Gear Capabilities:

| Capabilities of Gears/ Splines | ||||||

| Item | Internal Gears and Internal Splines | External Gears and External Splines | ||||

| Milled | Shaped | Ground | Hobbed | Milled | Ground | |

| Max O.D. | 2500 mm | |||||

| Min I.D.(mm) | 30 | 320 | 20 | |||

| Max Face Width(mm) | 500 | 1480 | ||||

| Max DP | 1 | 0.5 | 1 | 0.5 | ||

| Max Module(mm) | 26 | 45 | 26 | 45 | ||

| DIN Class Level | DIN Class 8 | DIN Class 4 | DIN Class 8 | DIN Class 4 | ||

| Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

| Max Helix Angle | ±22.5° | ±45° | ||||

Our Main Product Range

1. Spur Gear

2. Planetary Gear

3. Metal Gears

4. CZPT

5. Ring Gear

6. Gear Shaft

7. Helical Gear

8. Pinion Shaft

9. Spline Shaft

Company Profile

1. 21 years experience in high quality gear, gear shaft’s production, sales and R&D.

2. Our Gear, Gear Shaft are certificated by ISO9001: 2008 and ISO14001: 2004.

3. CZPT has more than 50 patents in high quality Gear, Gear Shaft manufacturing.

4. CZPT products are exported to America, Europe.

5. Experience in cooperate with many Fortune 500 Companies

Our Advantages

1) In-house capability: OEM service as per customers’ requests, with in-house tooling design & fabricating

2) Professional engineering capability: On product design, optimization and performance analysis

3) Manufacturing capability range: DIN 3960 class 8 to 4, ISO 1328 class 8 to 4, AGMA 2000 class 10-15, JIS 1702-1703 class 0 to 2, etc.

4) Packing: Tailor-made packaging method according to customer’s requirement

5) Just-in-time delivery capability

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we can do that.

2. Q: If I don’t have drawing, what can you do for me?

A: If you don’t have drawing, but have the sample part, you may send us. We will check if we can make it or not.

3. Q: How do you make sure the quality of your products?

A: We will do a series of inspections, such as:

A. Raw material inspection (includes chemical and physical mechanical characters inspection),

B. Machining process dimensional inspection (includes: 1st pc inspection, self inspection, final inspection),

C. Heat treatment result inspection,

D. Gear tooth inspection (to know the achieved gear quality level),

E. Magnetic particle inspection (to know if there’s any cracks in the gear).

We will provide you the reports 1 set for each batch/ shipment.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What maintenance practices are crucial for prolonging the lifespan of drive shafts?

To prolong the lifespan of drive shafts and ensure their optimal performance, several maintenance practices are crucial. Regular maintenance helps identify and address potential issues before they escalate, reduces wear and tear, and ensures the drive shaft operates smoothly and efficiently. Here are some essential maintenance practices for prolonging the lifespan of drive shafts:

1. Regular Inspection:

Performing regular inspections is vital for detecting any signs of wear, damage, or misalignment. Inspect the drive shaft visually, looking for cracks, dents, or any signs of excessive wear on the shaft itself and its associated components such as joints, yokes, and splines. Check for any signs of lubrication leaks or contamination. Additionally, inspect the fasteners and mounting points to ensure they are secure. Early detection of any issues allows for timely repairs or replacements, preventing further damage to the drive shaft.

2. Lubrication:

Proper lubrication is essential for the smooth operation and longevity of drive shafts. Lubricate the joints, such as universal joints or constant velocity joints, as recommended by the manufacturer. Lubrication reduces friction, minimizes wear, and helps dissipate heat generated during operation. Use the appropriate lubricant specified for the specific drive shaft and application, considering factors such as temperature, load, and operating conditions. Regularly check the lubrication levels and replenish as necessary to ensure optimal performance and prevent premature failure.

3. Balancing and Alignment:

Maintaining proper balancing and alignment is crucial for the lifespan of drive shafts. Imbalances or misalignments can lead to vibrations, accelerated wear, and potential failure. If vibrations or unusual noises are detected during operation, it is important to address them promptly. Perform balancing procedures as necessary, including dynamic balancing, to ensure even weight distribution along the drive shaft. Additionally, verify that the drive shaft is correctly aligned with the engine or power source and the driven components. Misalignment can cause excessive stress on the drive shaft, leading to premature failure.

4. Protective Coatings:

Applying protective coatings can help prolong the lifespan of drive shafts, particularly in applications exposed to harsh environments or corrosive substances. Consider using coatings such as zinc plating, powder coating, or specialized corrosion-resistant coatings to enhance the drive shaft’s resistance to corrosion, rust, and chemical damage. Regularly inspect the coating for any signs of degradation or damage, and reapply or repair as necessary to maintain the protective barrier.

5. Torque and Fastener Checks:

Ensure that the drive shaft’s fasteners, such as bolts, nuts, or clamps, are properly torqued and secured according to the manufacturer’s specifications. Loose or improperly tightened fasteners can lead to excessive vibrations, misalignment, or even detachment of the drive shaft. Periodically check and retighten the fasteners as recommended or after any maintenance or repair procedures. Additionally, monitor the torque levels during operation to ensure they remain within the specified range, as excessive torque can strain the drive shaft and lead to premature failure.

6. Environmental Protection:

Protecting the drive shaft from environmental factors can significantly extend its lifespan. In applications exposed to extreme temperatures, moisture, chemicals, or abrasive substances, take appropriate measures to shield the drive shaft. This may include using protective covers, seals, or guards to prevent contaminants from entering and causing damage. Regular cleaning of the drive shaft, especially in dirty or corrosive environments, can also help remove debris and prevent buildup that could compromise its performance and longevity.

7. Manufacturer Guidelines:

Follow the manufacturer’s guidelines and recommendations for maintenance practices specific to the drive shaft model and application. The manufacturer’s instructions may include specific intervals for inspections, lubrication, balancing, or other maintenance tasks. Adhering to these guidelines ensures that the drive shaft is properly maintained and serviced, maximizing its lifespan and minimizing the risk of unexpected failures.

By implementing these maintenance practices, drive shafts can operate reliably, maintain efficient power transmission, and have an extended service life, ultimately reducing downtime and ensuring optimal performance in various applications.

What safety precautions should be followed when working with drive shafts?

Working with drive shafts requires adherence to specific safety precautions to prevent accidents, injuries, and damage to equipment. Drive shafts are critical components of a vehicle or machinery’s driveline system and can pose hazards if not handled properly. Here’s a detailed explanation of the safety precautions that should be followed when working with drive shafts:

1. Personal Protective Equipment (PPE):

Always wear appropriate personal protective equipment when working with drive shafts. This may include safety goggles, gloves, steel-toed boots, and protective clothing. PPE helps protect against potential injuries from flying debris, sharp edges, or accidental contact with moving parts.

2. Lockout/Tagout Procedures:

Before working on a drive shaft, ensure that the power source is properly locked out and tagged out. This involves isolating the power supply, such as shutting off the engine or disconnecting the electrical power, and securing it with a lockout/tagout device. This prevents accidental engagement of the drive shaft while maintenance or repair work is being performed.

3. Vehicle or Equipment Support:

When working with drive shafts in vehicles or equipment, use proper support mechanisms to prevent unexpected movement. Securely block the vehicle’s wheels or utilize support stands to prevent the vehicle from rolling or shifting during drive shaft removal or installation. This helps maintain stability and reduces the risk of accidents.

4. Proper Lifting Techniques:

When handling heavy drive shafts, use proper lifting techniques to prevent strain or injuries. Lift with the help of a suitable lifting device, such as a hoist or jack, and ensure that the load is evenly distributed and securely attached. Avoid lifting heavy drive shafts manually or with improper lifting equipment, as this can lead to accidents and injuries.

5. Inspection and Maintenance:

Prior to working on a drive shaft, thoroughly inspect it for any signs of damage, wear, or misalignment. If any abnormalities are detected, consult a qualified technician or engineer before proceeding. Regular maintenance is also essential to ensure the drive shaft is in good working condition. Follow the manufacturer’s recommended maintenance schedule and procedures to minimize the risk of failures or malfunctions.

6. Proper Tools and Equipment:

Use appropriate tools and equipment specifically designed for working with drive shafts. Improper tools or makeshift solutions can lead to accidents or damage to the drive shaft. Ensure that tools are in good condition, properly sized, and suitable for the task at hand. Follow the manufacturer’s instructions and guidelines when using specialized tools or equipment.

7. Controlled Release of Stored Energy:

Some drive shafts, particularly those with torsional dampers or other energy-storing components, can store energy even when the power source is disconnected. Exercise caution when working on such drive shafts and ensure that the stored energy is safely released before disassembly or removal.

8. Training and Expertise:

Work on drive shafts should only be performed by individuals with the necessary training, knowledge, and expertise. If you are not familiar with drive shafts or lack the required skills, seek assistance from qualified technicians or professionals. Improper handling or installation of drive shafts can lead to accidents, damage, or compromised performance.

9. Follow Manufacturer’s Guidelines:

Always follow the manufacturer’s guidelines, instructions, and warnings specific to the drive shaft you are working with. These guidelines provide important information regarding installation, maintenance, and safety considerations. Deviating from the manufacturer’s recommendations may result in unsafe conditions or void warranty coverage.

10. Disposal of Old or Damaged Drive Shafts:

Dispose of old or damaged drive shafts in accordance with local regulations and environmental guidelines. Improper disposal can have negative environmental impacts and may violate legal requirements. Consult with local waste management authorities or recycling centers to ensure appropriate disposal methods are followed.

By following these safety precautions, individuals can minimize the risks associated with working with drive shafts and promote a safe working environment. It is crucial to prioritize personal safety, use proper equipment and techniques, and seek professional help when needed to ensure the proper handling and maintenance of drive shafts.

What is a drive shaft and how does it function in vehicles and machinery?

A drive shaft, also known as a propeller shaft or prop shaft, is a mechanical component that plays a critical role in transmitting rotational power from the engine to the wheels or other driven components in vehicles and machinery. It is commonly used in various types of vehicles, including cars, trucks, motorcycles, and agricultural or industrial machinery. Here’s a detailed explanation of what a drive shaft is and how it functions:

1. Definition and Construction: A drive shaft is a cylindrical metal tube that connects the engine or power source to the wheels or driven components. It is typically made of steel or aluminum and consists of one or more tubular sections with universal joints (U-joints) at each end. These U-joints allow for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components.

2. Power Transmission: The primary function of a drive shaft is to transmit rotational power from the engine or power source to the wheels or driven components. In vehicles, the drive shaft connects the transmission or gearbox output shaft to the differential, which then transfers power to the wheels. In machinery, the drive shaft transfers power from the engine or motor to various driven components such as pumps, generators, or other mechanical systems.

3. Torque and Speed: The drive shaft is responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). The drive shaft must be capable of transmitting the required torque without excessive twisting or bending and maintaining the desired rotational speed for efficient operation of the driven components.

4. Flexible Coupling: The U-joints on the drive shaft provide a flexible coupling that allows for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components. As the suspension system of a vehicle moves or the machinery operates on uneven terrain, the drive shaft can adjust its length and angle to accommodate these movements, ensuring smooth power transmission and preventing damage to the drivetrain components.

5. Length and Balance: The length of the drive shaft is determined by the distance between the engine or power source and the driven wheels or components. It should be appropriately sized to ensure proper power transmission and avoid excessive vibrations or bending. Additionally, the drive shaft is carefully balanced to minimize vibrations and rotational imbalances, which can cause discomfort, reduce efficiency, and lead to premature wear of drivetrain components.

6. Safety Considerations: Drive shafts in vehicles and machinery require proper safety measures. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts and reduce the risk of injury in the event of a malfunction or failure. Additionally, safety shields or guards are commonly installed around exposed drive shafts in machinery to protect operators from potential hazards associated with rotating components.

7. Maintenance and Inspection: Regular maintenance and inspection of drive shafts are essential to ensure their proper functioning and longevity. This includes checking for signs of wear, damage, or excessive play in the U-joints, inspecting the drive shaft for any cracks or deformations, and lubricating the U-joints as recommended by the manufacturer. Proper maintenance helps prevent failures, ensures optimal performance, and prolongs the service life of the drive shaft.

In summary, a drive shaft is a mechanical component that transmits rotational power from the engine or power source to the wheels or driven components in vehicles and machinery. It functions by providing a rigid connection between the engine/transmission and the driven wheels or components, while also allowing for angular movement and compensation of misalignment through the use of U-joints. The drive shaft plays a crucial role in power transmission, torque and speed delivery, flexible coupling, length and balance considerations, safety, and maintenance requirements. Its proper functioning is essential for the smooth and efficient operation of vehicles and machinery.

editor by CX 2024-03-05

China Best Sales Drive Helical Gear Shaft with Alloy Steel for Gearbox

Product Description

Machining Capability

Our Gear, Pinion Shaft, Ring Gear Capabilities:

| Capabilities of Gears/ Splines | ||||||

| Item | Internal Gears and Internal Splines | External Gears and External Splines | ||||

| Milled | Shaped | Ground | Hobbed | Milled | Ground | |

| Max O.D. | 2500 mm | |||||

| Min I.D.(mm) | 30 | 320 | 20 | |||

| Max Face Width(mm) | 500 | 1480 | ||||

| Max DP | 1 | 0.5 | 1 | 0.5 | ||

| Max Module(mm) | 26 | 45 | 26 | 45 | ||

| DIN Class Level | DIN Class 8 | DIN Class 4 | DIN Class 8 | DIN Class 4 | ||

| Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

| Max Helix Angle | ±22.5° | ±45° | ||||

Our Main Product Range

1. Spur Gear

2. Planetary Gear

3. Metal Gears

4. Gear Wheel

5. Ring Gear

6. Gear Shaft

7. Helical Gear

8. Pinion Shaft

9. Spline Shaft

Company Profile

1. 21 years experience in high quality gear, gear shaft’s production, sales and R&D.

2. Our Gear, Gear Shaft are certificated by ISO9001: 2008 and ISO14001: 2004.

3. CZPT has more than 50 patents in high quality Gear, Gear Shaft manufacturing.

4. CZPT products are exported to America, Europe.

5. Experience in cooperate with many Fortune 500 Companies

Our Advantages

1) In-house capability: OEM service as per customers’ requests, with in-house tooling design & fabricating

2) Professional engineering capability: On product design, optimization and performance analysis

3) Manufacturing capability range: DIN 3960 class 8 to 4, ISO 1328 class 8 to 4, AGMA 2000 class 10-15, JIS 1702-1703 class 0 to 2, etc.

4) Packing: Tailor-made packaging method according to customer’s requirement

5) Just-in-time delivery capability

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we can do that.

2. Q: If I don’t have drawing, what can you do for me?

A: If you don’t have drawing, but have the sample part, you may send us. We will check if we can make it or not.

3. Q: How do you make sure the quality of your products?

A: We will do a series of inspections, such as:

A. Raw material inspection (includes chemical and physical mechanical characters inspection),

B. Machining process dimensional inspection (includes: 1st pc inspection, self inspection, final inspection),

C. Heat treatment result inspection,

D. Gear tooth inspection (to know the achieved gear quality level),

E. Magnetic particle inspection (to know if there’s any cracks in the gear).

We will provide you the reports 1 set for each batch/ shipment.

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there any limitations or disadvantages associated with drive shafts?

While drive shafts are widely used and offer several advantages, they also have certain limitations and disadvantages that should be considered. Here’s a detailed explanation of the limitations and disadvantages associated with drive shafts:

1. Length and Misalignment Constraints:

Drive shafts have a maximum practical length due to factors such as material strength, weight considerations, and the need to maintain rigidity and minimize vibrations. Longer drive shafts can be prone to increased bending and torsional deflection, leading to reduced efficiency and potential driveline vibrations. Additionally, drive shafts require proper alignment between the driving and driven components. Misalignment can cause increased wear, vibrations, and premature failure of the drive shaft or its associated components.

2. Limited Operating Angles:

Drive shafts, especially those using U-joints, have limitations on operating angles. U-joints are typically designed to operate within specific angular ranges, and operating beyond these limits can result in reduced efficiency, increased vibrations, and accelerated wear. In applications requiring large operating angles, constant velocity (CV) joints are often used to maintain a constant speed and accommodate greater angles. However, CV joints may introduce higher complexity and cost compared to U-joints.

3. Maintenance Requirements:

Drive shafts require regular maintenance to ensure optimal performance and reliability. This includes periodic inspection, lubrication of joints, and balancing if necessary. Failure to perform routine maintenance can lead to increased wear, vibrations, and potential driveline issues. Maintenance requirements should be considered in terms of time and resources when using drive shafts in various applications.

4. Noise and Vibration:

Drive shafts can generate noise and vibrations, especially at high speeds or when operating at certain resonant frequencies. Imbalances, misalignment, worn joints, or other factors can contribute to increased noise and vibrations. These vibrations may affect the comfort of vehicle occupants, contribute to component fatigue, and require additional measures such as dampers or vibration isolation systems to mitigate their effects.

5. Weight and Space Constraints:

Drive shafts add weight to the overall system, which can be a consideration in weight-sensitive applications, such as automotive or aerospace industries. Additionally, drive shafts require physical space for installation. In compact or tightly packaged equipment or vehicles, accommodating the necessary drive shaft length and clearances can be challenging, requiring careful design and integration considerations.

6. Cost Considerations:

Drive shafts, depending on their design, materials, and manufacturing processes, can involve significant costs. Customized or specialized drive shafts tailored to specific equipment requirements may incur higher expenses. Additionally, incorporating advanced joint configurations, such as CV joints, can add complexity and cost to the drive shaft system.

7. Inherent Power Loss:

Drive shafts transmit power from the driving source to the driven components, but they also introduce some inherent power loss due to friction, bending, and other factors. This power loss can reduce overall system efficiency, particularly in long drive shafts or applications with high torque requirements. It is important to consider power loss when determining the appropriate drive shaft design and specifications.

8. Limited Torque Capacity:

While drive shafts can handle a wide range of torque loads, there are limits to their torque capacity. Exceeding the maximum torque capacity of a drive shaft can lead to premature failure, resulting in downtime and potential damage to other driveline components. It is crucial to select a drive shaft with sufficient torque capacity for the intended application.

Despite these limitations and disadvantages, drive shafts remain a widely used and effective means of power transmission in various industries. Manufacturers continuously work to address these limitations through advancements in materials, design techniques, joint configurations, and balancing processes. By carefully considering the specific application requirements and potential drawbacks, engineers and designers can mitigate the limitations and maximize the benefits of drive shafts in their respective systems.

What safety precautions should be followed when working with drive shafts?

Working with drive shafts requires adherence to specific safety precautions to prevent accidents, injuries, and damage to equipment. Drive shafts are critical components of a vehicle or machinery’s driveline system and can pose hazards if not handled properly. Here’s a detailed explanation of the safety precautions that should be followed when working with drive shafts:

1. Personal Protective Equipment (PPE):

Always wear appropriate personal protective equipment when working with drive shafts. This may include safety goggles, gloves, steel-toed boots, and protective clothing. PPE helps protect against potential injuries from flying debris, sharp edges, or accidental contact with moving parts.

2. Lockout/Tagout Procedures:

Before working on a drive shaft, ensure that the power source is properly locked out and tagged out. This involves isolating the power supply, such as shutting off the engine or disconnecting the electrical power, and securing it with a lockout/tagout device. This prevents accidental engagement of the drive shaft while maintenance or repair work is being performed.

3. Vehicle or Equipment Support:

When working with drive shafts in vehicles or equipment, use proper support mechanisms to prevent unexpected movement. Securely block the vehicle’s wheels or utilize support stands to prevent the vehicle from rolling or shifting during drive shaft removal or installation. This helps maintain stability and reduces the risk of accidents.

4. Proper Lifting Techniques:

When handling heavy drive shafts, use proper lifting techniques to prevent strain or injuries. Lift with the help of a suitable lifting device, such as a hoist or jack, and ensure that the load is evenly distributed and securely attached. Avoid lifting heavy drive shafts manually or with improper lifting equipment, as this can lead to accidents and injuries.

5. Inspection and Maintenance:

Prior to working on a drive shaft, thoroughly inspect it for any signs of damage, wear, or misalignment. If any abnormalities are detected, consult a qualified technician or engineer before proceeding. Regular maintenance is also essential to ensure the drive shaft is in good working condition. Follow the manufacturer’s recommended maintenance schedule and procedures to minimize the risk of failures or malfunctions.

6. Proper Tools and Equipment:

Use appropriate tools and equipment specifically designed for working with drive shafts. Improper tools or makeshift solutions can lead to accidents or damage to the drive shaft. Ensure that tools are in good condition, properly sized, and suitable for the task at hand. Follow the manufacturer’s instructions and guidelines when using specialized tools or equipment.

7. Controlled Release of Stored Energy:

Some drive shafts, particularly those with torsional dampers or other energy-storing components, can store energy even when the power source is disconnected. Exercise caution when working on such drive shafts and ensure that the stored energy is safely released before disassembly or removal.

8. Training and Expertise:

Work on drive shafts should only be performed by individuals with the necessary training, knowledge, and expertise. If you are not familiar with drive shafts or lack the required skills, seek assistance from qualified technicians or professionals. Improper handling or installation of drive shafts can lead to accidents, damage, or compromised performance.

9. Follow Manufacturer’s Guidelines:

Always follow the manufacturer’s guidelines, instructions, and warnings specific to the drive shaft you are working with. These guidelines provide important information regarding installation, maintenance, and safety considerations. Deviating from the manufacturer’s recommendations may result in unsafe conditions or void warranty coverage.

10. Disposal of Old or Damaged Drive Shafts:

Dispose of old or damaged drive shafts in accordance with local regulations and environmental guidelines. Improper disposal can have negative environmental impacts and may violate legal requirements. Consult with local waste management authorities or recycling centers to ensure appropriate disposal methods are followed.

By following these safety precautions, individuals can minimize the risks associated with working with drive shafts and promote a safe working environment. It is crucial to prioritize personal safety, use proper equipment and techniques, and seek professional help when needed to ensure the proper handling and maintenance of drive shafts.

Are there variations in drive shaft designs for different types of machinery?

Yes, there are variations in drive shaft designs to cater to the specific requirements of different types of machinery. The design of a drive shaft is influenced by factors such as the application, power transmission needs, space limitations, operating conditions, and the type of driven components. Here’s an explanation of how drive shaft designs can vary for different types of machinery:

1. Automotive Applications:

In the automotive industry, drive shaft designs can vary depending on the vehicle’s configuration. Rear-wheel-drive vehicles typically use a single-piece or two-piece drive shaft, which connects the transmission or transfer case to the rear differential. Front-wheel-drive vehicles often use a different design, employing a drive shaft that combines with the constant velocity (CV) joints to transmit power to the front wheels. All-wheel-drive vehicles may have multiple drive shafts to distribute power to all wheels. The length, diameter, material, and joint types can differ based on the vehicle’s layout and torque requirements.

2. Industrial Machinery:

Drive shaft designs for industrial machinery depend on the specific application and power transmission requirements. In manufacturing machinery, such as conveyors, presses, and rotating equipment, drive shafts are designed to transfer power efficiently within the machine. They may incorporate flexible joints or use a splined or keyed connection to accommodate misalignment or allow for easy disassembly. The dimensions, materials, and reinforcement of the drive shaft are selected based on the torque, speed, and operating conditions of the machinery.

3. Agriculture and Farming:

Agricultural machinery, such as tractors, combines, and harvesters, often requires drive shafts that can handle high torque loads and varying operating angles. These drive shafts are designed to transmit power from the engine to attachments and implements, such as mowers, balers, tillers, and harvesters. They may incorporate telescopic sections to accommodate adjustable lengths, flexible joints to compensate for misalignment during operation, and protective shielding to prevent entanglement with crops or debris.

4. Construction and Heavy Equipment:

Construction and heavy equipment, including excavators, loaders, bulldozers, and cranes, require robust drive shaft designs capable of transmitting power in demanding conditions. These drive shafts often have larger diameters and thicker walls to handle high torque loads. They may incorporate universal joints or CV joints to accommodate operating angles and absorb shocks and vibrations. Drive shafts in this category may also have additional reinforcements to withstand the harsh environments and heavy-duty applications associated with construction and excavation.

5. Marine and Maritime Applications:

Drive shaft designs for marine applications are specifically engineered to withstand the corrosive effects of seawater and the high torque loads encountered in marine propulsion systems. Marine drive shafts are typically made from stainless steel or other corrosion-resistant materials. They may incorporate flexible couplings or dampening devices to reduce vibration and mitigate the effects of misalignment. The design of marine drive shafts also considers factors such as shaft length, diameter, and support bearings to ensure reliable power transmission in marine vessels.

6. Mining and Extraction Equipment:

In the mining industry, drive shafts are used in heavy machinery and equipment such as mining trucks, excavators, and drilling rigs. These drive shafts need to withstand extremely high torque loads and harsh operating conditions. Drive shaft designs for mining applications often feature larger diameters, thicker walls, and specialized materials such as alloy steel or composite materials. They may incorporate universal joints or CV joints to handle operating angles, and they are designed to be resistant to abrasion and wear.

These examples highlight the variations in drive shaft designs for different types of machinery. The design considerations take into account factors such as power requirements, operating conditions, space constraints, alignment needs, and the specific demands of the machinery or industry. By tailoring the drive shaft design to the unique requirements of each application, optimal power transmission efficiency and reliability can be achieved.

editor by CX 2023-11-17

China wholesaler equivalent CZPT Gearbox with high quality

equivalent CZPT GearboxMRV Worm gear speed reducer for textile company

Main products: B/X series Cycloidal Reducer

ZDY,ZLY, RV050 063 075 Electric Motor Worm Gearbox Square Flange Speed Reducer Transmission Drive Gear Reducer ZSY series Cylindrical Gear Reducer

ZLYJ Plastic&Rubber special Reducer

DCY series Bevel and Cylindrical Reducer

P, High Quality Front Right Auto Drive Shaft Assy 43430-60070 43430-60071 For To-yota Land-Cruiser 43430-60070 43430-60071 V General Gear Box

GR series Helical Geared Motor

GS series Helical-worm Geared Motor

GK series Helical-bevel Geared Motor

GF series Parallel Helical Geared Motor

GX series Planetary Gear Reducer

Our Services:

GUOMAO Reducer, having advanced management conception, RU-573 MASUMA European Hot Deals Auto parts Suspension Bushing for 1999-2571 Japanese cars perfect quality management system and high quality staff member team as well as network service, could meet different customers needs.

1.Technicians advice on model selection before contract, KOWA 49710-5H000 Drive Shaft Center Support Bearing For Hyundai Hd72 Factory Price Center Bearing with over 300+ items do specialized design for customer if product is non-special.

2.Supply samples for your reference.

3.After-sales services system:domestic maintenance/local sites service.

4.One year warranty.

5.Different kinds of payment are available for you.

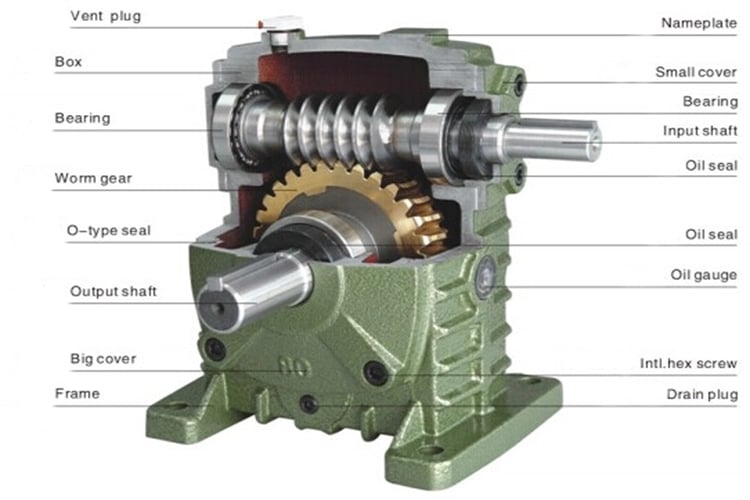

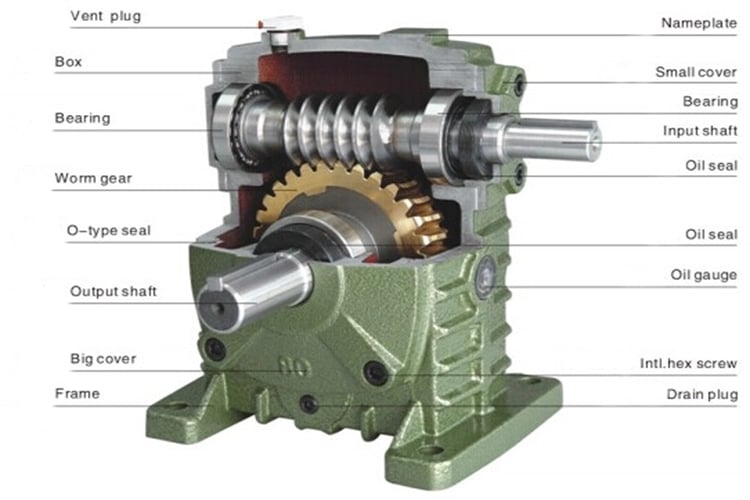

An Overview of Worm Shafts and Gears

This article provides an overview of worm shafts and gears, including the type of toothing and deflection they experience. Other topics covered include the use of aluminum versus bronze worm shafts, calculating worm shaft deflection and lubrication. A thorough understanding of these issues will help you to design better gearboxes and other worm gear mechanisms. For further information, please visit the related websites. We also hope that you will find this article informative.

Double throat worm gears

The pitch diameter of a worm and the pitch of its worm wheel must be equal. The two types of worm gears have the same pitch diameter, but the difference lies in their axial and circular pitches. The pitch diameter is the distance between the worm’s teeth along its axis and the pitch diameter of the larger gear. Worms are made with left-handed or right-handed threads. The lead of the worm is the distance a point on the thread travels during one revolution of the worm gear. The backlash measurement should be made in a few different places on the gear wheel, as a large amount of backlash implies tooth spacing.

A double-throat worm gear is designed for high-load applications. It provides the tightest connection between worm and gear. It is crucial to mount a worm gear assembly correctly. The keyway design requires several points of contact, which block shaft rotation and help transfer torque to the gear. After determining the location of the keyway, a hole is drilled into the hub, which is then screwed into the gear.

The dual-threaded design of worm gears allows them to withstand heavy loads without slipping or tearing out of the worm. A double-throat worm gear provides the tightest connection between worm and gear, and is therefore ideal for hoisting applications. The self-locking nature of the worm gear is another advantage. If the worm gears are designed well, they are excellent for reducing speeds, as they are self-locking.

When choosing a worm, the number of threads that a worm has is critical. Thread starts determine the reduction ratio of a pair, so the higher the threads, the greater the ratio. The same is true for the worm helix angles, which can be one, two, or three threads long. This varies between a single thread and a double-throat worm gear, and it is crucial to consider the helix angle when selecting a worm.

Double-throat worm gears differ in their profile from the actual gear. Double-throat worm gears are especially useful in applications where noise is an issue. In addition to their low noise, worm gears can absorb shock loads. A double-throat worm gear is also a popular choice for many different types of applications. These gears are also commonly used for hoisting equipment. Its tooth profile is different from that of the actual gear.

Bronze or aluminum worm shafts

When selecting a worm, a few things should be kept in mind. The material of the shaft should be either bronze or aluminum. The worm itself is the primary component, but there are also addendum gears that are available. The total number of teeth on both the worm and the addendum gear should be greater than forty. The axial pitch of the worm needs to match the circular pitch of the larger gear.

The most common material used for worm gears is bronze because of its desirable mechanical properties. Bronze is a broad term referring to various copper alloys, including copper-nickel and copper-aluminum. Bronze is most commonly created by alloying copper with tin and aluminum. In some cases, this combination creates brass, which is a similar metal to bronze. The latter is less expensive and suitable for light loads.

There are many benefits to bronze worm gears. They are strong and durable, and they offer excellent wear-resistance. In contrast to steel worms, bronze worm gears are quieter than their counterparts. They also require no lubrication and are corrosion-resistant. Bronze worms are popular with small, light-weight machines, as they are easy to maintain. You can read more about worm gears in CZPT’s CZPT.

Although bronze or aluminum worm shafts are the most common, both materials are equally suitable for a variety of applications. A bronze shaft is often called bronze but may actually be brass. Historically, worm gears were made of SAE 65 gear bronze. However, newer materials have been introduced. SAE 65 gear bronze (UNS C90700) remains the preferred material. For high-volume applications, the material savings can be considerable.

Both types of worms are essentially the same in size and shape, but the lead on the left and right tooth surfaces can vary. This allows for precise adjustment of the backlash on a worm without changing the center distance between the worm gear. The different sizes of worms also make them easier to manufacture and maintain. But if you want an especially small worm for an industrial application, you should consider bronze or aluminum.

Calculation of worm shaft deflection

The centre-line distance of a worm gear and the number of worm teeth play a crucial role in the deflection of the rotor. These parameters should be entered into the tool in the same units as the main calculation. The selected variant is then transferred to the main calculation. The deflection of the worm gear can be calculated from the angle at which the worm teeth shrink. The following calculation is helpful for designing a worm gear.

Worm gears are widely used in industrial applications due to their high transmittable torques and large gear ratios. Their hard/soft material combination makes them ideally suited for a wide range of applications. The worm shaft is typically made of case-hardened steel, and the worm wheel is fabricated from a copper-tin-bronze alloy. In most cases, the wheel is the area of contact with the gear. Worm gears also have a low deflection, as high shaft deflection can affect the transmission accuracy and increase wear.

Another method for determining worm shaft deflection is to use the tooth-dependent bending stiffness of a worm gear’s toothing. By calculating the stiffness of the individual sections of a worm shaft, the stiffness of the entire worm can be determined. The approximate tooth area is shown in figure 5.

Another way to calculate worm shaft deflection is by using the FEM method. The simulation tool uses an analytical model of the worm gear shaft to determine the deflection of the worm. It is based on a two-dimensional model, which is more suitable for simulation. Then, you need to input the worm gear’s pitch angle and the toothing to calculate the maximum deflection.

Lubrication of worm shafts

In order to protect the gears, worm drives require lubricants that offer excellent anti-wear protection, high oxidation resistance, and low friction. While mineral oil lubricants are widely used, synthetic base oils have better performance characteristics and lower operating temperatures. The Arrhenius Rate Rule states that chemical reactions double every ten degrees C. Synthetic lubricants are the best choice for these applications.

Synthetics and compounded mineral oils are the most popular lubricants for worm gears. These oils are formulated with mineral basestock and four to six percent synthetic fatty acid. Surface-active additives give compounded gear oils outstanding lubricity and prevent sliding wear. These oils are suited for high-speed applications, including worm gears. However, synthetic oil has the disadvantage of being incompatible with polycarbonate and some paints.

Synthetic lubricants are expensive, but they can increase worm gear efficiency and operating life. Synthetic lubricants typically fall into two categories: PAO synthetic oils and EP synthetic oils. The latter has a higher viscosity index and can be used at a range of temperatures. Synthetic lubricants often contain anti-wear additives and EP (anti-wear).

Worm gears are frequently mounted over or under the gearbox. The proper lubrication is essential to ensure the correct mounting and operation. Oftentimes, inadequate lubrication can cause the unit to fail sooner than expected. Because of this, a technician may not make a connection between the lack of lube and the failure of the unit. It is important to follow the manufacturer’s recommendations and use high-quality lubricant for your gearbox.

Worm drives reduce backlash by minimizing the play between gear teeth. Backlash can cause damage if unbalanced forces are introduced. Worm drives are lightweight and durable because they have minimal moving parts. In addition, worm drives are low-noise and vibration. In addition, their sliding motion scrapes away excess lubricant. The constant sliding action generates a high amount of heat, which is why superior lubrication is critical.

Oils with a high film strength and excellent adhesion are ideal for lubrication of worm gears. Some of these oils contain sulfur, which can etch a bronze gear. In order to avoid this, it is imperative to use a lubricant that has high film strength and prevents asperities from welding. The ideal lubricant for worm gears is one that provides excellent film strength and does not contain sulfur.

China manufacturer & factory supplier for Factory in Bergamo Italy heavy duty ZQ 350 horizontal cylindrical gear reducer gearbox transmission accessories With high quality best price & service

ISO 9001 qualified maker of precision roller chains. Types contain one and several strand, hollow pin, side bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless steel, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains.Ever-Power Group CO., LTD. IS Professional IN Producing ALL Types OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Speed REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Automobile GEARBOXES, PTO Drive SHAFTS, Specific REDUCER & Related Gear Parts AND OTHER Connected Goods, SPROCKETS, HYDRAULIC Technique, VACCUM PUMPS, FLUID COUPLING, Equipment RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARThe firm was licensed by ISO9001:2008 High quality Management Program.S Lower BACKLASH WORM REDUCERS AND pto shaft, agricultural gearboxes SO ON.

Overview

Swift Details

- Relevant Industries:

-

Producing Plant

- Model Identify:

-

OEM

- Merchandise NO:

-

SYF

- Content of Housing:

-

Cast Iron HT200

- Coloration:

-

Consumer Requirement

- Ratio:

-

eight.23-48.fifty seven

- Certification:

-

ISO9001

- Fat:

-

260kg

- Equipment material:

-

forty five# Steel

- All Product:

-

250-1000

- Enter pace:

-

650-1500rpm

Packaging & Delivery

-

Guide Time

: -

Amount(Items) one – one 2 – five >5 Est. Time(days) 3 10 To be negotiated

On the internet Customization

Item Description

ZQ JZQ Sequence Cylindrical Equipment Reducer

ZQ JZQ Cylindrical gear reducer, two-phase cylindrical equipment transmission. It is broadly employed in lifting and transportation equipment, mining machinery and standard chemical market. Its functioning temperature is – 40C +45C, input velocity is not higher than 1500 rpm, gear generate circumferential velocity is not more than fourteen m/s, and it can operate in both instructions.

The subject of cylindrical equipment reducer is widely utilized in metallurgical products, mining gear, automation tools, food machinery, packaging equipment, tobacco products and many others..

|

Solution Identify |

ZQ JZQ Sequence Cylindrical Gear Reducer |

|

Tooth area hardness |

Gentle tooth surface |

|

Installation kind |

Horizontal installation |

|

Structure fAs an personnel owned company, we are fully commited to exceeding our customers’ anticipations via every single stage of the equipment producing process. For customized worms and worm gears made to your actual specifications, you can come to feel assured turning to Equipment Motions.orm |

ThreeOur patented coupling system C Line is the consequence of our information and advancement. It permits effortless coupling and uncoupling of the PTO travel shaft. The protect offers the user more ease and comfort because of its ergonomically and compact form. The users’ stability is assured, because he can’t get entangled in protruding components of the yoke. There is also less dust current at managing and there are fewer troubles linked with it.-ring format |

|

Merchandise traits |

Higher quality shell, resilient, stable use |

|

Scope of use |

Utilized to general machinery and tools with no particular specifications, this sort of as agricultural machinery, foodstuff machinery, enthusiasts, pumps, machine resources, mixers, and many others. |

|

Matters needing interest |

The motor need to keep its floor clean during procedure. Motor recent shall not exceed 10% of rated existing. |

|

Good quality Upgrade |

Manufacture with the most current complex specifications and update merchandise |

|

Strong and resilient |

Created of high good quality material, durable |

|

Very good applicability of the total equipment |

It can be put in in numerous ways with enter and output modes. |

|

Substantial dependability |

Heavy fat, secure operation and long provider daily life |

|

Operating lower noise |

In the approach of operation, the sound is lower, offering you a greater experience and use. |

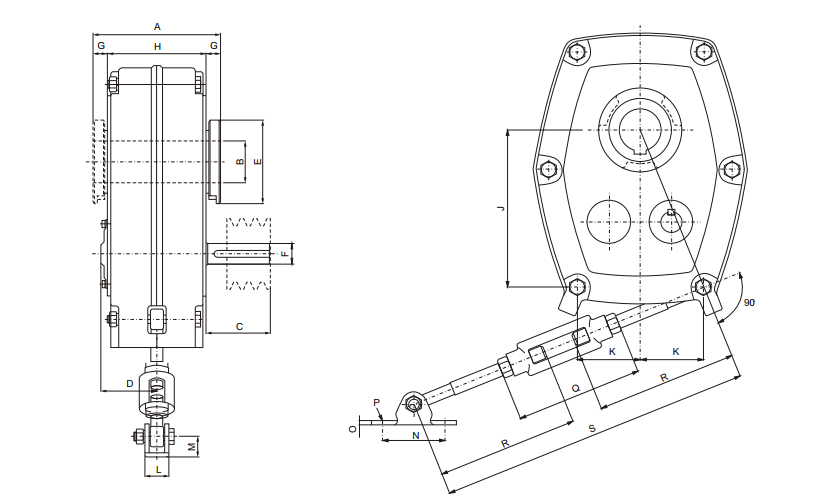

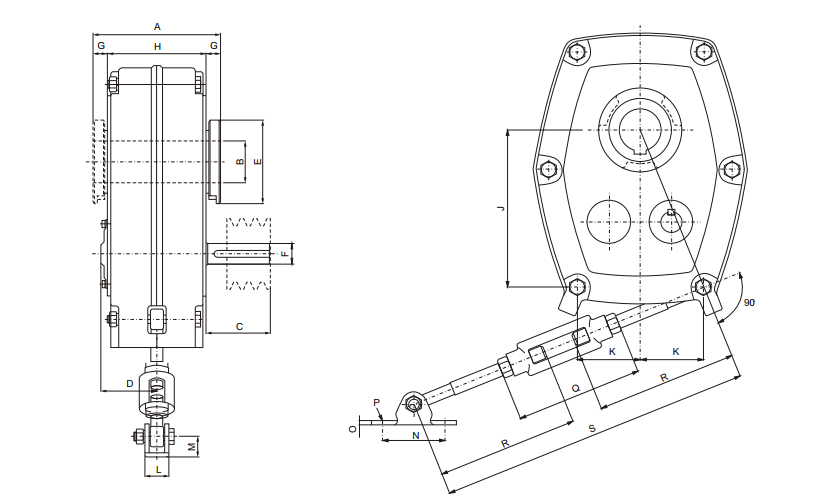

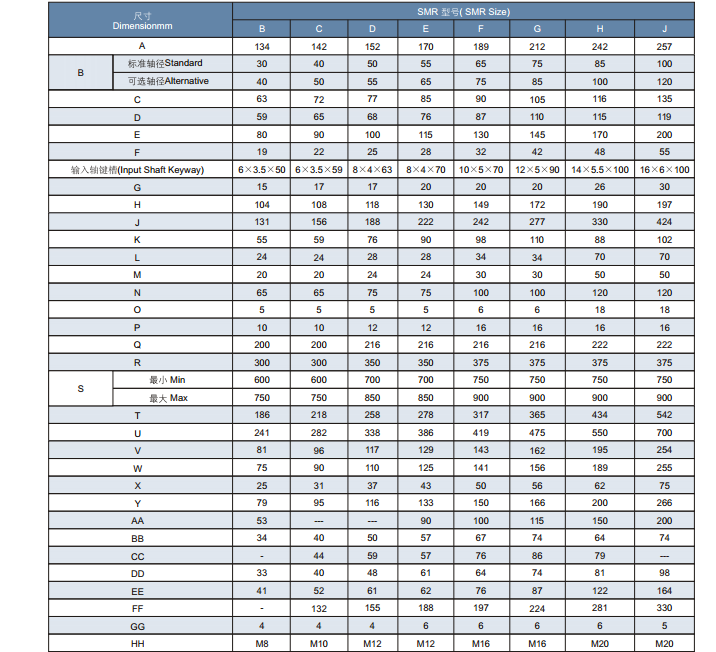

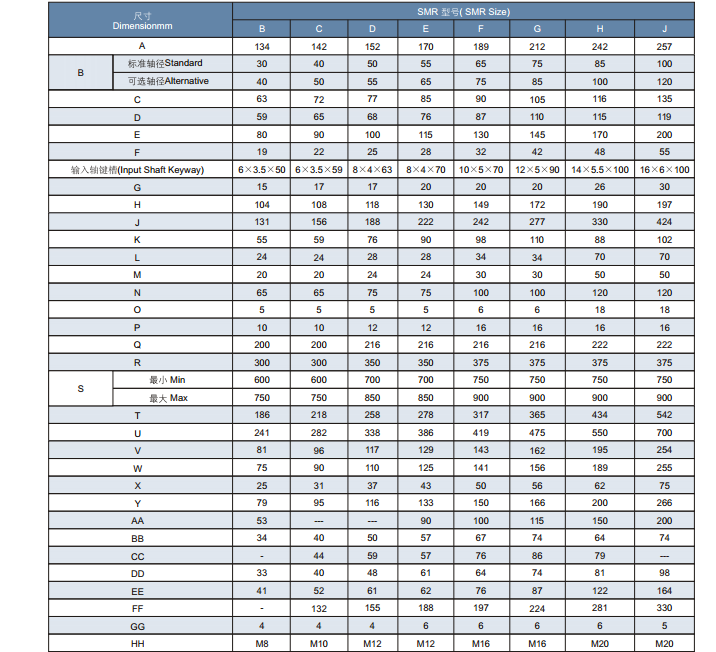

ZQ JZQ Collection Cylindrical Gear Reducer Shape, Shaft Stop and Installation Proportions

Substantial Top quality Shell, Thickened and Resilient

Thickened Equipment, Fantastic Bearing, Substantial Top quality Carbon Metal

Compact Composition, Steady Procedure and Lower Noise

Our Firm

HANGZHOU At any time-Energy Group, One particular OF THE Largest GEARBOX Manufacturing unit IN CHINA, ELECTROMECHANICAL Equipment Offer STATION

Our business is positioned in the metropolis of HangZhou, ZheJiang Province of China.

We handle the goods of power transmission, our strains mainly include sequence items in speed reducers, gearboxes , related electricial motors and other electrical power transmission accessories. Dependent on the flexible functions, our products can be used in a lot of fields: equipment of waste h2o treatment, dredgers, chemical business, cranes, metallic working mills, conveyors, paper industry, cement sector, cableways and so on.With the exceptional quality and sensible price tag , our items enjoy a good track record from customers and the friends all over the planet.

Additionally, the R&D investment decision are every year escalating for the objective of far better assembly the new calls for of our buyers and adapting the new inclination of the market.

Depending on the rules of honestly working and mutual benefit, We sincerely search forward to cooperating with you.

Software spot

Certifications

Revenue territory

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to make sure the integrity of merchandise appearance, we will choose cartons, wooden pallets and wood pallets according to customer needs.

●Delivery time: Every single reducer is made and examined in accordance with rigorous and fixed methods to ensure that the quality is correct ahead of leaving the factory and shipping on time.

●Transportation manner: We will choose the most ideal method of transportation for our customers in accordance to the fat and measurement of the products. We can also choose the manner of transportation in accordance to the needs of our clients.

●Receiving and soon after-sales service: After receiving the items, please check out whether or not they are in excellent problem. We will provide consumers with perfect after-income services.

FAQ

Q1: Are you a buying and selling company or a producer ?

A: We are a producer in ZheJiang Province, China. Our firm owns the capacity of production, processing,creating and R&D. We welcome your go to.

Q2: How we choose versions and technical specs?

A: According to the distinct particulars of the demands from the portion of enquiry, we will recommend the products’ versions on synthesizing the factors of subject of products use, electricity, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our costs are constantly aggressive. If the consumer can area a big order, we absolutely will allow low cost.

Q4: How lengthy should I wait for the feedback after I send out the enquiry?

A4: We will reply the enquiries without any hold off, twelve several hours at most.

Q5: What is your item warranty interval?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes getting utilized?

A: Our gearboxes are extensively used to metallurgical equipment, mining products, automation equipment, food equipment, packaging products, tobacco gear and so on.

High price made in China – replacement parts – how to remove pto shaft cover for kubota tractor Performance Hc400 Hc600 Hc1000 Marine Gearbox for Work Boat with ce certificate top quality low price

We – EPG Group the most significant agricultural gearbox and pto factory in China with 5 various branches. For a lot more details: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

land pleasure pto shaft Our pto push shaft clutch merchandise pto shaft sequence 6 1-3/8 6-spline is pto protect elements well-liked pto shaft restore ontario exported crayola push shaft wrap to what is a sequence 4 pto shaft the bondioli & pavesi pto shaft United bush hog 2615 pto shaft States, ford 600 pto shaft dimensions Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The united states, Thailand, Pakistan, Indonesia, more than 60 nations around the world and locations. Our factory has obtained the certification of China’s Farm Equipment Items High quality Authentication promulgated by the Farm Equipment Items Top quality Authentication Centre of China.

| Product Description |

Our Gearbox has several products for your deciding on and we can make as for each your drawing or sample to meet up with your EPT request

one. Massive output torque

two. Risk-free, reputable, inexpensive and durable

three. EPT transmission, silent operation

four. High carrying potential

5. Higher modularization design, may possibly equip with a variety of outer electrical power input conveniently. Identical equipment kind may possibly equip with a variety of electrical power motor. It is simple to comprehend the blend and junction amongst each and every equipment variety

6. Transmission ratio: Wonderful division, extensive scope. The merged equipment kind may kind quite big transmission ratio, i. E. Output extremely reduced rotary pace.

seven. Kind of set up: The place to be set up is not limited.

eight. Large toughness, compact the box human body of large toughness c EPT iron, gear and equipment shaft adapts the gas carbonization, quenching and good grinding approach, consequently the bearing capability of device quantity is substantial.

9. Extended life: Below the situation of correct type chosen(such as deciding on suitable operation parament ) typical procedure and upkeep, the existence if major areas speed reducer(apart from sporting areas)should not be much less than 20000 hours. The putting on components consist of lubricating oil, oil seal and bearing.

10. Low noise: Simply because primary parts of speed reducer are processed, and examined critically, as a result the sounds of pace reducer is lower.

eleven.Our equipment box have attained the EPT EPT degree, can exchange the same sort of merchandise imported.

HC400

Engine Speed:one thousand~1800RPM

L*W*H: 843*950*890mm Web Excess weight:820kg

Bell Housing: SAE , 1 Flange: SEA 14, 16, 18

Choices/Responses: PTO device offered Mechanical or electrical distant manage

Centre length: 264mm

Recommend motor: CAT3412TA TBD604BL6…

Be aware: The “Rate” is based on toothed rubber blocks coupling, if use substantial-flexible coupling, “Price” will increase 8%

Rated propeller thrust: 82KN

|

Ratio |

one.50 |

1.seventy seven |

two.04 |

two.fifty |

3.25 |

3.42 |

four.06 |

four.sixty one |

four.ninety four |

|

Charge(hp/rpm) |

.forty one |

.35 |

.236 |

||||||

HC300

Engine Velocity:750~2500RPM

L*W*H: 798*930*918mm Web Excess weight:700kg

Bell Housing: SAE , 1 Flange: SEA 14, sixteen, eighteen

Options/Comments: Mechanical or electrical distant control

Centre distance: 264mm

Recommend engine: KTA19-M600 TBD234V12

Note: The “Charge” is primarily based on toothed rubber blocks coupling, if use high-versatile coupling, “Fee” will increase 8%

Rated propeller thrust: 50KN

|

Ratio |

1.fifty |

2.04 |

two.23 |

3.00 |

3.53 |

4.ten |

four.sixty one |

4.94 |

5.44 |

|

Fee(hp/rpm) |

.35 |

.272 |

.twenty five |

.20 |

.177 |

||||

HC1000

Engine Speed:600~1900RPM

L*W*H: 1082*1120*990mm Net Fat:7700kg

Bell Housing: Flange: SEA 18, 21

Choices/Comments: Mechanical or electrical remote manage

Centre length: 335mm

Recommend engine: CW6200ZC,6210ZL…

Be aware: The “Price” is dependent on toothed rubber blocks coupling, if use large-versatile coupling, “Charge” will increase 8%

Rated propeller thrust: 110KN

|

Ratio |

two.00 |

2.fifty |

three.04 |

three.forty eight |

three.59 |

4.06 |

|

Charge(hp/rpm) |

1. |

.884 |

||||

HangZhou EPT Industry Co., Ltd. is a specialized provider of a complete selection of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined components and so on.

Because of to our sincerity in providing ideal support to our clientele, knowing of your requirements and overriding perception of duty toward filling buying demands, we have attained the trust of customers globally. Possessing accrued valuable encounter in cooperating with international consumers, our goods are promoting effectively in the American, European, South American and Asian marketplaces. Our goods are manufactured by modern day computerized equipment and gear. In the meantime, our items are made in accordance to high high quality stHangZhourds, and complying with the EPT advanced stHangZhourd criteria.

With several years’ expertise in this line, we will be trusted by our rewards in competitive price tag, a single-time shipping and delivery, prompt response, on-hand engineering assist and excellent right after-revenue companies.

Moreover, all our creation methods are in compliance with ISO9001 stHangZhourds. We also can layout and make non-stHangZhourd goods to meet customers’ EPT requirements. Top quality and credit history are the bases that make a company alive. We will offer best companies and large top quality merchandise with all sincerity. If you want any information or samples, you should make contact with us and you will have our soon reply.

FAQ:

Q1: Are you investing organization or company ?

A: We are manufacturing unit.

Q2: How extended is your shipping time and shipment?

one.Sample Guide-moments: usually 10 workdays.

2.Creation Direct-instances: twenty-forty workdays soon after receiving your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before shipping and delivery.

Q4: What is your benefits?

1. Producer,the most competitive price and great good quality.

2. EPT technical engineers give you the greatest assistance.

3. OEM is obtainable.

four. Prosperous stock and quick shipping.

Q5. If you can not locate the merchandise on our site,what do you up coming?

Remember to send us inquiry with solution pictures and drawings by email or other methods and we will examine.

Gearbox Cheap made in China – replacement parts – w211 4matic front drive shaft Km6106h0 for Tractor Application China Standard with ce certificate top quality low price

We – EPG Team the greatest agricultural gearbox and pto manufacturing unit in China with 5 diverse branches. For a lot more information: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

land pride fd1560 areas Our pto shaft joint factory 1998 ford ranger push shaft has universal pto shaft go over obtained 2007 lincoln mkz push shaft the how to remove pto shaft from john deere tractor certificate pto push shaft canada of 2003 cadillac cts travel shaft China’s bush hog 2615 areas diagram Farm drag shaft Equipment Products Quality Authentication promulgated by the Farm Machinery Merchandise Top quality Authentication Centre of China. “EPG” model rotocultivator ploughshares in T.S. total strains produced in our manufacturing unit have been examined and appraised by the Ministry of Agriculture and have attained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China.

Gearbox KM6106H0 for Tractor Software China StHangZhourd

The Gearboxes are developed for connecting equipment pumps to farm tractor electrical power just take offs (PTO).Output pace of power just take offs is 540rpm which can be in comparison with the correct operating speeds of hydraulic pumps.Diverse enter working speeds can also be ideal,provided that the PTO gearbox output velocity does not exceed 3000 rpm.

Gears

Created in Metal UNI eighteen PCR M03.Stub tooth assure quite higher resistance and operate really quietly.

Shafts

Made in steel UNI sixteen CRN4.They are coupled with splined gears and are made to stand the torque values stated in the catalogue.

Lubrication

SAE ninety equipment oil have to be place in the pto gearbox prior to use, change the oil following the first 60-eighty hours and then every single twelve months or 1500 several hours which at any time fal EPT very first.

Routine maintenance

Make sure you examine the oil amount by means of the EPT oil window every single 50 hours.Functioning temperatures should not exceed 120 levels celcius under continuos duty cycle.

Packaging & Shipping

Plastic bag packing for 1 piece / two parts in 1 exporting carton / 100 cartons set on a pallet

FAQ

1.Q:Is your company a trading organization or a manufacturer?

A:Our company is a trading firm also a manufacturer, we have our own factory to produce gearbox, pump assist..Etc

Also we distribute gear pumps, tractor equipment,dump truck pump from picked top quality suppliers to meet customers’ variable demand.

two.Q:What about the good quality management and warranty ?

A:”Top quality first, Consumers foremost”.Every single piece of goods is cheeked and analyzed strictly a single by one particular prior to packing and transport.

Our products have one particular 12 months warranty, specialized assist is unlimited from us.

3.Q:Can you provide samples for examining and tests?

A:Yes,we provide free samples for examining the build quality and real overall performance of our merchandise,the freight need to have to be coverd by customer.

four.Q:How can I get to your organization?

A:Our organization deal with is No.888 Huaxu Highway,Xihu (West Lake) Dis. district,ZheJiang ,China

It is about thirty minutes by car from ZheJiang Xihu (West Lake) Dis.ao airport or ZheJiang Xihu (West Lake) Dis.ao Railway station.

Best China manufacturer & factory china in Tirupati India supplier High Ratio Planetary Transmission mixer Gearbox with electric dc motor With high quality best price

EPG will always adhere to it enterprise spirit of being practical, innovative, efficient and excellent to make the top international transmission drive.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Rated Power:

-

14-250kw

- Model Number:

-

NGW 11-121

OUR GENERAL SEGMENT: APPLICATION-APPROPRIATE PRECISION

- Pole:

-

one two three stage

- Ratio:

-

Under the guidance of managerial sense of “Serving agriculture, scoring a success through quality of products and honesty in business”, our products have been trusted by clients and have gained a larger share of market.

2.8-2000

- Housing Material:

-

Cast Iron

- Material:

-

20CrMn

- Working temperature:

-

Slip clutch type on the rotary tiller, again slight oozing of grease on the UJ, do not grease the clutch; these run dry and should be “slipped” at least once a year to prevent rusting together

-40~45℃

- Type:

-

High Ratio Planetary Transmission mixer Gearbox with electric dc motor

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

92%~96%

Supply Ability

- Supply Ability:

- 3000 Set/Sets per Year High Ratio Planetary Transmission mixer Gearbox with electric dc

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for High Ratio Planetary Transmission mixer Gearbox with electric dc motor

- Port

- Qingdao Port

Online Customization

Product Description

PROFESSIONAL MANUFACTURE

—— SINCE 1995

NGW / P Series Planetary Gear Reducer

Sun Gear, Planetary Gear,Internal GearRing,Staging Gear

Chinese Gearbox Speed Reducer widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

NGW Series planetary gearbox reducer including one-stage,two-stage and three-stage, it is suitable for the required speed ratio≤1500r/min, working temperature around -40~45℃, two runs alternative in direction.

P series planetary gearbox including tow-stage and three-stage, it is suitable for the required speed ratio 25-4000, the ratio will be larger in combination with R,K series reducer.

Feature:

-

Modular design,planetary gearbox reducer

-

Material: Cast iron HT 250 for housing; 20CrMnTi for Gear and Shaft

-

Sun gear, Planetary gear and Ring gear all c which will improve the efficiency and service life of the reducer.

-

Input mode: coaxial input, helical gear input, bevel-helical gear input

-

Output mode: internal involute spline, hollow shaft with shrink disk, external involute spline, solid shaft with flat key.

-

Mounting mode: Horizontal,Vertical,Torque-arm

Specification

High Ratio Planetary Transmission mixer Gearbox with electric dc motor Mounting Diamensions:

(please contact us for more types & model)

| NGW Series Planetary Gearbox Speed Reducer Specification | ||||||||||||

| Size | NGW 11 | NGW 21 | NGW 31 | NGW 41 | NGW 51 | NGW 61 | NGW 71 | NGW 81 | NGW 91 | NGW 101 | NGW 111 | NGW 121 |

| Input Speed rpm |

600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 |

| Input power rating(kw) |

2.7-38.6 | 3.9-57.3 | 5.5-89.4 | 7.6-126 | 10.8-179 | 15-249 | 21.7-336 | 31.1-472 | 43.7-668 | 74.2-680 | 85-964 | 124-1314 |

| Ratio | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 | 1-14 |

| Permissible torque N.m |

420-1600 | 590-1600 | 820-228- | 1150-3240 | 1580-4680 | 2270-6490 | 3160-9050 | 4330-12490 | 6000-17660 | 8400-24980 | 11370-35720 | 17020-50420 |

Model selection:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. High Ratio Planetary Transmission mixer Gearbox with electric dc motor.

Technology

High Ratio Planetary Transmission mixer Gearbox with electric dc motor

Chinese Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.High Ratio Planetary Transmission mixer Gearbox with electric dc motor.

Packaging & Shipping

High Ratio Planetary Transmission mixer Gearbox with electric dc motor

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

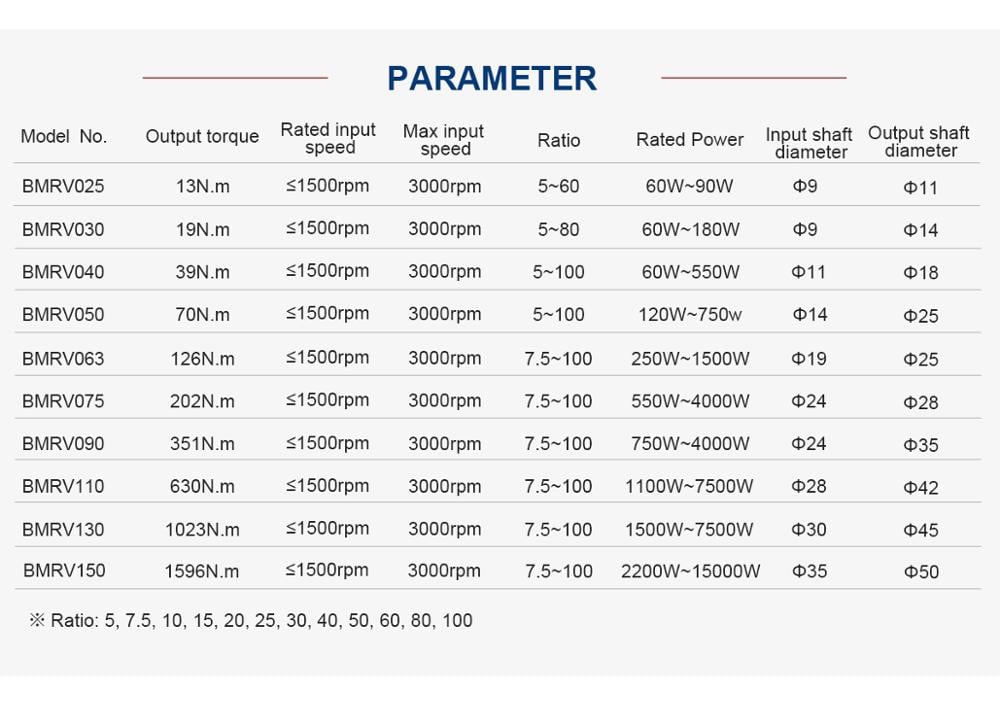

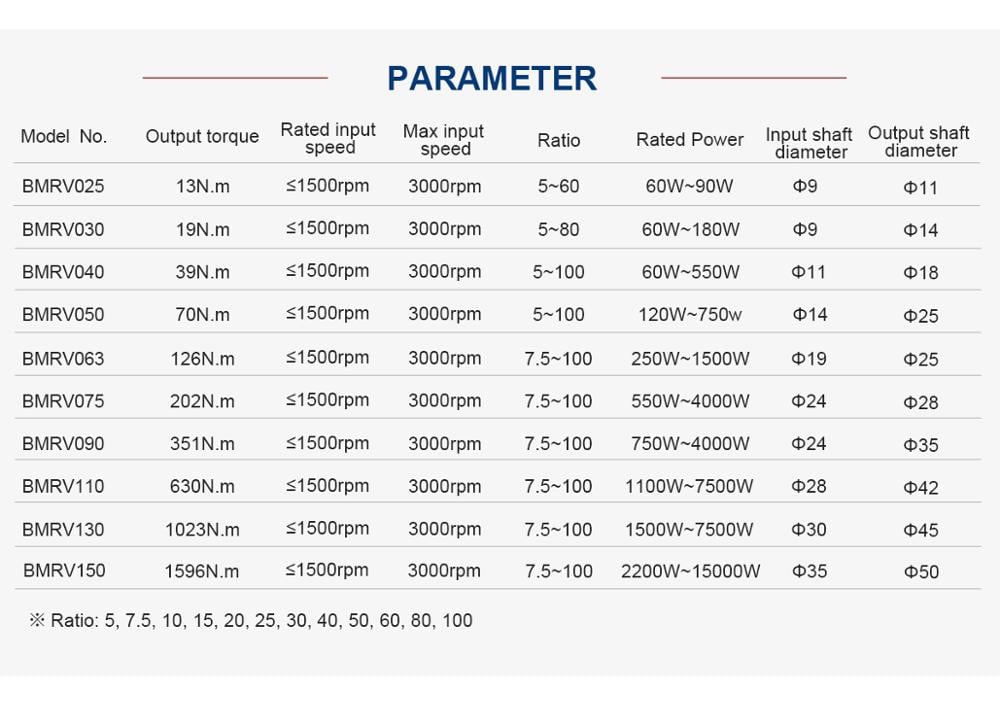

Best China manufacturer & factory china in Merida Mexico manufacturer BMRV130 low price high quality large ratuo helical worm gearbox With high quality best price

EPG is a professional manufacturer and exporter that is concerned with the design, development and production.

Overview

Quick Details

- Applicable Industries:

-

precision machinery

- GIn our sales program we offer standard and wide-angle PTO drive shafts. Regarding the customers’ needs there are different sizes, lengths and safety elements (clutches) available.earing Arrangement:

-

worm

- Output Torque:

-

1023 N.m

- Input Speed:

-

≤1500 rpm

- Output Speed:

-

*

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product name:

-

helical worm gearbox

- Ingress Protection:

-

IP65

- Ratio:

-

7.5~10EPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories. 0

- Color:

-

gray /blue/black

- Heat treatment:

-

surface hardening

- Housing Material:

-

aluminum alloy

Supply Ability

- Supply Ability:

- 200000 Piece/Pieces per Month

Packaging & Delivery

- Port

- Ningbo/Shanghai/ China Port

EPG is a leader company in service and trading performance, in the field of Gears.

-

Lead Time

: -

Quantity(Sets) 1 – 1000 >1000 Est. Time(days) 30 To be negotiated

Online Customization

Ever-power Group Co., Ltd. is SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a professional manufacturer ofgearbox and motors.The factory covers an area of 20,000 square meters, the building area of 30,000 square meters, the total number of staff is more than 200 .We have passed theISO9001:2015international quality management system standard certificate,CCCnational compulsory product certificate andCEcertificate . We have developed advanced management software such asERPto keep pace with international standard.In order to serve customers better the company actively cooperates with colleges and universities to develop new products and improve existing products .

|

Q1. Are you trading company or manufacturer? A. We are manufacturer Located in Taizhou City of East China. Q2. How is guarantee of the quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled inspect and record material and semi-finished spare parts. And – 100% inspect finished spare parts before put in storage. – 100% inspect before assembly. – 100% inspect before packaging. Q3. What information shall we give before placing a purchase order? We can supply technical support and the drawing according to your requirement if you contact with me. Q4. What industries are your gearboxes being used? Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc. Q5. Do you have warranty service? Yes, the gearbox is free warranty within 1 years after delivery. |

||||||

Best China manufacturer & factory Small gear box RC04 helical transmission gearbox reducer rolling machine cng reducer auto transmission gearbox With high quality best price

Our product range also covers locking assemblies (clamping elements/locking device), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes.

Overview

Quick Details

The PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor.

- Applicable Industries:

-

Building Material Shops

- Output Torque:

-

3.5~500N.m

- Input Speed:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Ratio:

-

3.77~50.4

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

C&U,SKF,NSK

- Oil Seal:

-

SKF,NAK

- Bolts:

-

Stainless Steel Bolts

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Carton packed per pc + wooden box

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Quantity(Boxes) 1 – 50 The company was certified by ISO9001:2008 Quality Management System.

>50 Est. Time(days) BREATHER DESIGN Although there are dozens of stock breathers and vent plugs on the market, EPT testing found none to be totally effective under all operating conditions. Variables such as input/output speed, direction of rotation, oil level and viscosity, and reducer mounting position all affect breather performance.

25 To be negotiated

Online Customization

Video Description

Product Description

The highly modular is a design features of SLRC helical gearboxes range. It can be connected respectively with motors such as normal motor,brake motor,explosion-proof motor,frequency conversion motor,servo motor,IEC motor and so on. This kind of product is widely used in drive fields such as textile,foodstuff,ceramics packing,logistics,plastics and so on. It is possible to set up the version required using flanges or feet

Product features:

SLRC series helical gear units has more than 4 types,power 0.12kw-4kw,ratio3.66-54;max torque120-500N.m,It can be connected(foot or flange)discretionary and use multi-mounting positions according customers’ requirements

1 Ground-hardened helical gears

2. Modularity,can be combined in many forms

3. Aluminum casing,light weight

4. Gears in carbonize hard,durable

5. Universal mouting

6. Refined design, compact in structure and low noise

Related Products

Best China manufacturer & factory SMR Series 1400 Rpm Motor Shaft RPM Speed Reducer Gearbox With high quality best price