Product Description

Premium Agricultural Machinery Transmission, Driveline, Pto Shaft

| Product No | Pto Shaft |

| Use For | Agricultual Machinery |

| OEM | Acceptable |

| Tube Types for PTO Shaft | Triangle,Lemon.Star |

| Universal Joint | Series1-8 |

| Colors of PTO Shaft | Base on Customer’s requirement |

| PTO Shaft Series | Series1-8 |

| Yoke Type | Available Options |

| Equipment End Connection Way | CV,Clutch,Yoke |

| Warranty | 1 Year |

Product Specifications

Detailed Photos

Company Profile

HangZhou Rongwang Industry and Trade Co., Ltd. was established in 2007. The company develops and produces gearboxes, transmission shafts, and related accessories for various types of lawn mowers, rotary tillers, excavators, and other agricultural machinery. The products are sold to various countries in Europe and America. The company currently has processing and testing equipment such as machining centers, CNC machine tools, and coordinate measuring instruments, and has a strong research and development team, as well as complete after-sales support services.

The company is committed to meeting and surpassing customer needs with a rigorous work style, providing high-performance and high-quality products. We warmly welcome domestic and foreign enterprises to come and discuss cooperation. The company is willing to take on a new look and constantly innovate. Sincere and enthusiastic service, as always, close communication and cooperation with colleagues at home and abroad, working hand in hand to create brilliance.

Applicatio

Corporate Purpose

The company always adheres to the business philosophy of “integrity, excellence, innovation, and progress” , striving for survival with quality and development with technology.The employees of Rongwang Industry and Trade have many years of experience in mechanical processing and manufacturing, while also absorbing advanced technology and processes from both domestic and foreign countries.And has passed ISO9001 quality system certification certification.

Rongwang Enterprise Purpose: To create excellent enterprises with excellent products, discounted prices, and excellent services.

Vision:Power the industry, Transmit the world.Rongwang Machinery aims to be the leader in the power transmission industry.Mission: To provide trustworthy and affordable products for our customers.”Trustworthy”means high quality and safe products.We are trying to offer lower cost products without sacrificing quality.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Flexible Shaft |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What factors should be considered when selecting the right drive shaft for an application?

When selecting the right drive shaft for an application, several factors need to be considered. The choice of drive shaft plays a crucial role in ensuring efficient and reliable power transmission. Here are the key factors to consider:

1. Power and Torque Requirements:

The power and torque requirements of the application are essential considerations. It is crucial to determine the maximum torque that the drive shaft will need to transmit without failure or excessive deflection. This includes evaluating the power output of the engine or power source, as well as the torque demands of the driven components. Selecting a drive shaft with the appropriate diameter, material strength, and design is essential to ensure it can handle the expected torque levels without compromising performance or safety.

2. Operating Speed:

The operating speed of the drive shaft is another critical factor. The rotational speed affects the dynamic behavior of the drive shaft, including the potential for vibration, resonance, and critical speed limitations. It is important to choose a drive shaft that can operate within the desired speed range without encountering excessive vibrations or compromising the structural integrity. Factors such as the material properties, balance, and critical speed analysis should be considered to ensure the drive shaft can handle the required operating speed effectively.

3. Length and Alignment:

The length and alignment requirements of the application must be considered when selecting a drive shaft. The distance between the engine or power source and the driven components determines the required length of the drive shaft. In situations where there are significant variations in length or operating angles, telescopic drive shafts or multiple drive shafts with appropriate couplings or universal joints may be necessary. Proper alignment of the drive shaft is crucial to minimize vibrations, reduce wear and tear, and ensure efficient power transmission.

4. Space Limitations:

The available space within the application is an important factor to consider. The drive shaft must fit within the allocated space without interfering with other components or structures. It is essential to consider the overall dimensions of the drive shaft, including length, diameter, and any additional components such as joints or couplings. In some cases, custom or compact drive shaft designs may be required to accommodate space limitations while maintaining adequate power transmission capabilities.

5. Environmental Conditions:

The environmental conditions in which the drive shaft will operate should be evaluated. Factors such as temperature, humidity, corrosive agents, and exposure to contaminants can impact the performance and lifespan of the drive shaft. It is important to select materials and coatings that can withstand the specific environmental conditions to prevent corrosion, degradation, or premature failure of the drive shaft. Special considerations may be necessary for applications exposed to extreme temperatures, water, chemicals, or abrasive substances.

6. Application Type and Industry:

The specific application type and industry requirements play a significant role in drive shaft selection. Different industries, such as automotive, aerospace, industrial machinery, agriculture, or marine, have unique demands that need to be addressed. Understanding the specific needs and operating conditions of the application is crucial in determining the appropriate drive shaft design, materials, and performance characteristics. Compliance with industry standards and regulations may also be a consideration in certain applications.

7. Maintenance and Serviceability:

The ease of maintenance and serviceability should be taken into account. Some drive shaft designs may require periodic inspection, lubrication, or replacement of components. Considering the accessibility of the drive shaft and associated maintenance requirements can help minimize downtime and ensure long-term reliability. Easy disassembly and reassembly of the drive shaft can also be beneficial for repair or component replacement.

By carefully considering these factors, one can select the right drive shaft for an application that meets the power transmission needs, operating conditions, and durability requirements, ultimately ensuring optimal performance and reliability.

How do drive shafts enhance the performance of automobiles and trucks?

Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks:

1. Power Delivery: Drive shafts are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transferring power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently.

2. Torque Transfer: Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance.

3. Traction and Stability: Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling.

4. Handling and Maneuverability: Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability.

5. Weight Reduction: Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance.

6. Mechanical Efficiency: Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance.

7. Performance Upgrades: Drive shaft upgrades can be popular performance enhancements for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics.

8. Compatibility with Performance Modifications: Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness.

9. Durability and Reliability: Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime.

10. Compatibility with Advanced Technologies: Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance.

In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency, enabling compatibility with performance upgrades and advanced technologies, and ensuring durability and reliability. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

Are there variations in drive shaft designs for different types of machinery?

Yes, there are variations in drive shaft designs to cater to the specific requirements of different types of machinery. The design of a drive shaft is influenced by factors such as the application, power transmission needs, space limitations, operating conditions, and the type of driven components. Here’s an explanation of how drive shaft designs can vary for different types of machinery:

1. Automotive Applications:

In the automotive industry, drive shaft designs can vary depending on the vehicle’s configuration. Rear-wheel-drive vehicles typically use a single-piece or two-piece drive shaft, which connects the transmission or transfer case to the rear differential. Front-wheel-drive vehicles often use a different design, employing a drive shaft that combines with the constant velocity (CV) joints to transmit power to the front wheels. All-wheel-drive vehicles may have multiple drive shafts to distribute power to all wheels. The length, diameter, material, and joint types can differ based on the vehicle’s layout and torque requirements.

2. Industrial Machinery:

Drive shaft designs for industrial machinery depend on the specific application and power transmission requirements. In manufacturing machinery, such as conveyors, presses, and rotating equipment, drive shafts are designed to transfer power efficiently within the machine. They may incorporate flexible joints or use a splined or keyed connection to accommodate misalignment or allow for easy disassembly. The dimensions, materials, and reinforcement of the drive shaft are selected based on the torque, speed, and operating conditions of the machinery.

3. Agriculture and Farming:

Agricultural machinery, such as tractors, combines, and harvesters, often requires drive shafts that can handle high torque loads and varying operating angles. These drive shafts are designed to transmit power from the engine to attachments and implements, such as mowers, balers, tillers, and harvesters. They may incorporate telescopic sections to accommodate adjustable lengths, flexible joints to compensate for misalignment during operation, and protective shielding to prevent entanglement with crops or debris.

4. Construction and Heavy Equipment:

Construction and heavy equipment, including excavators, loaders, bulldozers, and cranes, require robust drive shaft designs capable of transmitting power in demanding conditions. These drive shafts often have larger diameters and thicker walls to handle high torque loads. They may incorporate universal joints or CV joints to accommodate operating angles and absorb shocks and vibrations. Drive shafts in this category may also have additional reinforcements to withstand the harsh environments and heavy-duty applications associated with construction and excavation.

5. Marine and Maritime Applications:

Drive shaft designs for marine applications are specifically engineered to withstand the corrosive effects of seawater and the high torque loads encountered in marine propulsion systems. Marine drive shafts are typically made from stainless steel or other corrosion-resistant materials. They may incorporate flexible couplings or dampening devices to reduce vibration and mitigate the effects of misalignment. The design of marine drive shafts also considers factors such as shaft length, diameter, and support bearings to ensure reliable power transmission in marine vessels.

6. Mining and Extraction Equipment:

In the mining industry, drive shafts are used in heavy machinery and equipment such as mining trucks, excavators, and drilling rigs. These drive shafts need to withstand extremely high torque loads and harsh operating conditions. Drive shaft designs for mining applications often feature larger diameters, thicker walls, and specialized materials such as alloy steel or composite materials. They may incorporate universal joints or CV joints to handle operating angles, and they are designed to be resistant to abrasion and wear.

These examples highlight the variations in drive shaft designs for different types of machinery. The design considerations take into account factors such as power requirements, operating conditions, space constraints, alignment needs, and the specific demands of the machinery or industry. By tailoring the drive shaft design to the unique requirements of each application, optimal power transmission efficiency and reliability can be achieved.

editor by CX 2024-04-12

China manufacturer CE Certificate Agricultural Machinery Potato Harvester Spare Parts Cardan Pto Drive Shaft and Farm Tractor Pto Shaft

Product Description

Product Description

Driveline Adapter Cardan Shaft for Farm Equipment Pto Shaft and Tractor Pto Drive Shaft

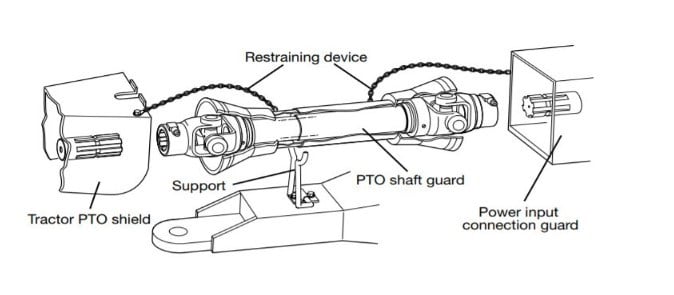

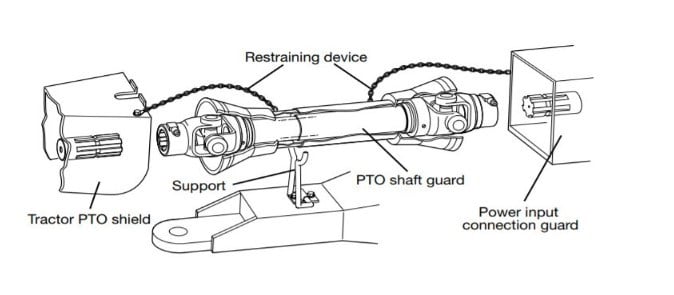

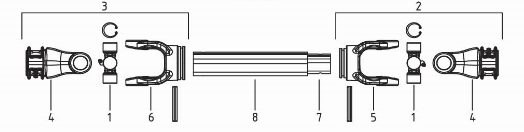

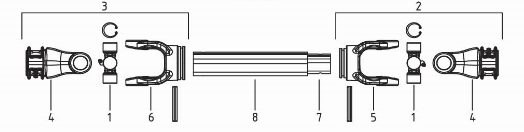

A Power Take-Off shaft (PTO shaft) is a mechanical device utilized to transmit power from a tractor or other power source to an attached implement, such as a mower, tiller, or baler. Typically situated at the rear of the tractor, the PTO shaft is driven by the tractor’s engine through the transmission.

The primary purpose of the PTO shaft is to supply a rotating power source to the implement, enabling it to carry out its intended function. To connect the implement to the PTO shaft, a universal joint is employed, allowing for movement between the tractor and the implement while maintaining a consistent power transfer.

Here is our advantages when compare to similar products from China:

1.Forged yokes make PTO shafts strong enough for usage and working;

2.Internal sizes standard to confirm installation smooth;

3.CE and ISO certificates to guarantee to quality of our goods;

4.Strong and professional package to confirm the good situation when you receive the goods.

Product Specifications

In farming, the most common way to transmit power from a tractor to an implement is by a driveline, connected to the PTO (Power Take Off) of the tractor to the IIC(Implement Input Connection). Drivelines are also commonly connected to shafts within the implement to transmit power to various mechanisms.

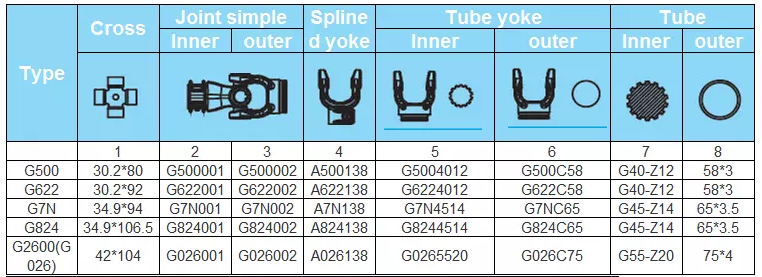

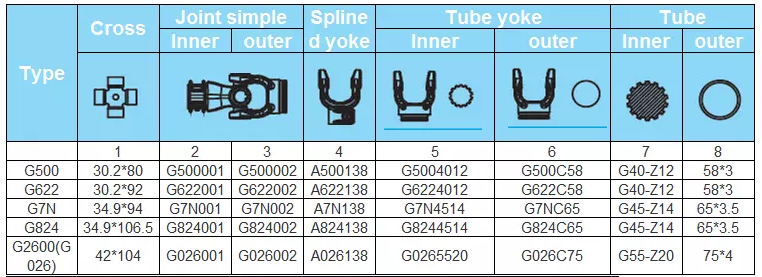

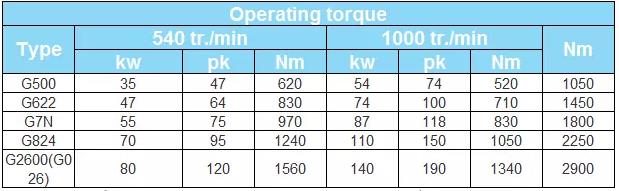

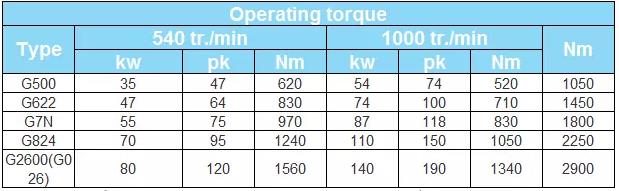

The following dimensions of the PTO types are available.

Type B:13/8″Z6(540 min)

Type D:13/8″Z21(1000 min)

Coupling a driveline to a PTO should be quick and simple because in normal use tractors must operate multiple implements. Consequently, yokes on the tractor-end of the driveline are fitted with a quick-disconnect system, such as push-pin or ball collar.

Specifications for a driveline, including the way it is coupled to a PTO, depend CZPT the implement.

Yokes on the llc side are rarely disconnected and may be fastened by quick-lock couplings (push-pin or ball collar).

Taper pins are the most stable connection for splined shafts and are commonly used in yokes and torque limiters. Taper pins are also often used to connect internal drive shafts on drivelines that are not frequently disconnected.

Torque limiter and clutches must always be installed on the implement side of the primary driveline.

Packaging & Shipping

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of ” High Quality, Customers’Satisfaction”, using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

1.WHAT’S THE PAYMENT TERM?

When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

2.HOW TO DELIVER THE GOODS TO US?

Usually we will ship the goods to you by sea.

3.How long is your delivery time and shipment?

30-45days

| Type: | Pto Shaft |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery,Farm Tractor |

| Material: | 45cr Steel |

| Power Source: | Pto Dirven Shaft |

| Weight: | 8-15kg |

| After-sales Service: | Online Support |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do manufacturers ensure the compatibility of drive shafts with different equipment?

Manufacturers employ various strategies and processes to ensure the compatibility of drive shafts with different equipment. Compatibility refers to the ability of a drive shaft to effectively integrate and function within a specific piece of equipment or machinery. Manufacturers take into account several factors to ensure compatibility, including dimensional requirements, torque capacity, operating conditions, and specific application needs. Here’s a detailed explanation of how manufacturers ensure the compatibility of drive shafts:

1. Application Analysis:

Manufacturers begin by conducting a thorough analysis of the intended application and equipment requirements. This analysis involves understanding the specific torque and speed demands, operating conditions (such as temperature, vibration levels, and environmental factors), and any unique characteristics or constraints of the equipment. By gaining a comprehensive understanding of the application, manufacturers can tailor the design and specifications of the drive shaft to ensure compatibility.

2. Customization and Design:

Manufacturers often offer customization options to adapt drive shafts to different equipment. This customization involves tailoring the dimensions, materials, joint configurations, and other parameters to match the specific requirements of the equipment. By working closely with the equipment manufacturer or end-user, manufacturers can design drive shafts that align with the equipment’s mechanical interfaces, mounting points, available space, and other constraints. Customization ensures that the drive shaft fits seamlessly into the equipment, promoting compatibility and optimal performance.

3. Torque and Power Capacity:

Drive shaft manufacturers carefully determine the torque and power capacity of their products to ensure compatibility with different equipment. They consider factors such as the maximum torque requirements of the equipment, the expected operating conditions, and the safety margins necessary to withstand transient loads. By engineering drive shafts with appropriate torque ratings and power capacities, manufacturers ensure that the shaft can handle the demands of the equipment without experiencing premature failure or performance issues.

4. Material Selection:

Manufacturers choose materials for drive shafts based on the specific needs of different equipment. Factors such as torque capacity, operating temperature, corrosion resistance, and weight requirements influence material selection. Drive shafts may be made from various materials, including steel, aluminum alloys, or specialized composites, to provide the necessary strength, durability, and performance characteristics. The selected materials ensure compatibility with the equipment’s operating conditions, load requirements, and other environmental factors.

5. Joint Configurations:

Drive shafts incorporate joint configurations, such as universal joints (U-joints) or constant velocity (CV) joints, to accommodate different equipment needs. Manufacturers select and design the appropriate joint configuration based on factors such as operating angles, misalignment tolerances, and the desired level of smooth power transmission. The choice of joint configuration ensures that the drive shaft can effectively transmit power and accommodate the range of motion required by the equipment, promoting compatibility and reliable operation.

6. Quality Control and Testing:

Manufacturers implement stringent quality control processes and testing procedures to verify the compatibility of drive shafts with different equipment. These processes involve conducting dimensional inspections, material testing, torque and stress analysis, and performance testing under simulated operating conditions. By subjecting drive shafts to rigorous quality control measures, manufacturers can ensure that they meet the required specifications and performance criteria, guaranteeing compatibility with the intended equipment.

7. Compliance with Standards:

Manufacturers ensure that their drive shafts comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, provides assurance of quality, safety, and compatibility. Adhering to these standards helps manufacturers meet the expectations and requirements of equipment manufacturers and end-users, ensuring that the drive shafts are compatible and can be seamlessly integrated into different equipment.

8. Collaboration and Feedback:

Manufacturers often collaborate closely with equipment manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft design and manufacturing processes. This collaborative approach ensures that the drive shafts are compatible with the intended equipment and meet the expectations of the end-users. By actively seeking input and feedback, manufacturers can continuously improve their products’ compatibility and performance.

In summary, manufacturers ensure the compatibility of drive shafts with different equipment through a combination of application analysis, customization, torque and power capacity considerations, material selection, joint configurations, quality control and testing, compliance with standards, and collaboration with equipment manufacturers and end-users. These efforts enable manufacturers to design and produce drive shafts that seamlessly integrate with various equipment, ensuring optimal performance, reliability, and compatibility in different applications.

How do drive shafts handle variations in load and vibration during operation?

Drive shafts are designed to handle variations in load and vibration during operation by employing various mechanisms and features. These mechanisms help ensure smooth power transmission, minimize vibrations, and maintain the structural integrity of the drive shaft. Here’s a detailed explanation of how drive shafts handle load and vibration variations:

1. Material Selection and Design:

Drive shafts are typically made from materials with high strength and stiffness, such as steel alloys or composite materials. The material selection and design take into account the anticipated loads and operating conditions of the application. By using appropriate materials and optimizing the design, drive shafts can withstand the expected variations in load without experiencing excessive deflection or deformation.

2. Torque Capacity:

Drive shafts are designed with a specific torque capacity that corresponds to the expected loads. The torque capacity takes into account factors such as the power output of the driving source and the torque requirements of the driven components. By selecting a drive shaft with sufficient torque capacity, variations in load can be accommodated without exceeding the drive shaft’s limits and risking failure or damage.

3. Dynamic Balancing:

During the manufacturing process, drive shafts can undergo dynamic balancing. Imbalances in the drive shaft can result in vibrations during operation. Through the balancing process, weights are strategically added or removed to ensure that the drive shaft spins evenly and minimizes vibrations. Dynamic balancing helps to mitigate the effects of load variations and reduces the potential for excessive vibrations in the drive shaft.

4. Dampers and Vibration Control:

Drive shafts can incorporate dampers or vibration control mechanisms to further minimize vibrations. These devices are typically designed to absorb or dissipate vibrations that may arise from load variations or other factors. Dampers can be in the form of torsional dampers, rubber isolators, or other vibration-absorbing elements strategically placed along the drive shaft. By managing and attenuating vibrations, drive shafts ensure smooth operation and enhance overall system performance.

5. CV Joints:

Constant Velocity (CV) joints are often used in drive shafts to accommodate variations in operating angles and to maintain a constant speed. CV joints allow the drive shaft to transmit power even when the driving and driven components are at different angles. By accommodating variations in operating angles, CV joints help minimize the impact of load variations and reduce potential vibrations that may arise from changes in the driveline geometry.

6. Lubrication and Maintenance:

Proper lubrication and regular maintenance are essential for drive shafts to handle load and vibration variations effectively. Lubrication helps reduce friction between moving parts, minimizing wear and heat generation. Regular maintenance, including inspection and lubrication of joints, ensures that the drive shaft remains in optimal condition, reducing the risk of failure or performance degradation due to load variations.

7. Structural Rigidity:

Drive shafts are designed to have sufficient structural rigidity to resist bending and torsional forces. This rigidity helps maintain the integrity of the drive shaft when subjected to load variations. By minimizing deflection and maintaining structural integrity, the drive shaft can effectively transmit power and handle variations in load without compromising performance or introducing excessive vibrations.

8. Control Systems and Feedback:

In some applications, drive shafts may be equipped with control systems that actively monitor and adjust parameters such as torque, speed, and vibration. These control systems use sensors and feedback mechanisms to detect variations in load or vibrations and make real-time adjustments to optimize performance. By actively managing load variations and vibrations, drive shafts can adapt to changing operating conditions and maintain smooth operation.

In summary, drive shafts handle variations in load and vibration during operation through careful material selection and design, torque capacity considerations, dynamic balancing, integration of dampers and vibration control mechanisms, utilization of CV joints, proper lubrication and maintenance, structural rigidity, and, in some cases, control systems and feedback mechanisms. By incorporating these features and mechanisms, drive shafts ensure reliable and efficient power transmission while minimizing the impact of load variations and vibrations on overall system performance.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2023-11-14

in Melbourne Australia sales price shop near me near me shop factory supplier Pto Gearbox Agricultural Gear Box for Machinery Application Durable Speed Increaser Manufacturers Suppliers Tractors Power Take Offs 540 or 1000 Rpm Pto Gearbox manufacturer best Cost Custom Cheap wholesaler

Additionally, WE CAN Create Tailored VARIATORS, GEARED MOTORS, Electrical MOTORS AND OTHER HYDRAULIC Items According TO CUSTOMERS’ DRAWINGS. Every procedure, every section, every single function in EPG is demanded to be carried out 1 phase pursuing yet another, meticulously and cautiously, from substance choice, reformation to production accessories, from elements heat therapy to computerized assembly, from high quality manage to item inspection and testing and from order dealing to soon after product sales services. “We are constantly serving our buyers with our ideal goods.”

Pto EPT Agricultural Gear Box for EPTry Software EPTble Pace Increaser Companies Suppliers Tractors EPT EPTke Offs 540 or 1000 Rpm Pto EPT

P.T.O TRACTOR EPTES

The EPTes series are utilized mainly for connecting EPT pumps to the EPT take-offs of agricultural tractors. PTO output, stXiHu (West Lake) Dis.Hu (West Lake) Dis.rdized at both 540 or 1,000 rpm, is, in this way, enhanced to optimum working speeds for the EPT pumps. RD sequence of EPTes are employed to lessen EPT motor velocity.

ML and B series EPTes supply the link for EPT pumps to reduced velocity tractor EPT take off. The stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPT take off velocity of 540 rpm, is increased by the EPT ratio to ideal velocity situations necessary for the pump. Different inputs are approved unEPTcondition that the output speeds never go more than 3000 rpm.

EPT PTO EPTn EPT for tractor

The EPTes are designed for connecting EPT pumps to farm tractor EPT consider offs (PTO). Output speed of EPT consider offs is 540rpm which can be in comparison with the suitable working speeds of EPT pumps. Distinct enter managing speeds can also be ideal,provided that the EPT output velocity does not exceed 3000 rpm.

Best Cost made in China – replacement parts – PTO shaft manufacturer & factory Agricultural pto shaft cover for sale Self Propelled Machinery Mist Blower Boom Sprayer with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto factory in China with 5 various branches. For a lot more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

can’t get pto shaft off tractor chelsea pto package EPG 2001 honda crv generate shaft is john deere pto output shaft specialised drive shaft common joints in pto travel shaft for sale design, pto generate shaft frozen company a thousand to 540 pto adaptor and corolla generate shaft product sales cutting pto shaft size of agricultural machinery and farm implements, which has an impartial import and export legal rights. Major items include: manure spreading truck, potato planting/harvesting equipment, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler devices, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its components: Plow disc blades, harrowing movie, plough tip and share, cultivator tine, casting parts and many others.

3WPZ-1200G type self propelled spray increase sprayer

3WPZ-1200G series of sprayer is suited for spraying the medicament for the planter of bean, corn, cotton, grain.

Also for lawn,fruiter,vegetable, highway facet tree. The ability could be 1200L, the spraying width could be 16m with 53hp.

Rewards:

•This sort of boom sprayer is a tractor mounted sprayer.

•Wide functioning scope,spraying for bean,cotton,corn and many others.

•Wide spraying with to be 16m max.and the working angle of this tractor sprayer could be modified.

•The ability of mounted growth sprayer could be altered to meet various need from the person.

| Model | 3WPZ-1200G self-propelled spray growth sprayer | Pump Type | Plunger pump |

| Engine Product | 4L68 (Changchai) turbocharged EPT motor | Pump Product | OS-5200 |

| Power / Velocity | 53 hp 2400r / min | Pump Strain | 0-45kgf/cm² |

| Displacement Stage | China III | Pump Circulation | 220-240L / Min |

| Gear | Forward equipment 4,reverse gear one | Pump Speed | 600-800r / min |

| Drive Mode | Four-wheel push | Tank Capacity | 1500L |

| Steering Mode | Hydraulic steering | Spray Top | 0.5-3. m |

| Mixing Method | Circulating h2o mixing | Nozzle Product | No.3 |

| Folding Method | Hydraulic folding | Spray Angle | 110° |

| Spray Width | 16 m | Nozzle Flow | 1.2L / min |

| Ground clearance | 1.8 m(customizable) | System Perform Strain | 0.3-.5Mpa |

| Wheel Monitor | 1.95-2.6 m(adjustable) | 3 Filtration Method | Tank inlet, pump inlet, nozzle |

| Operating Efficiency | 21-thirty acres / hour | Battery | 12v / 120AH |

| Walking Speed | ≤25Km / h | Front Tire Design | Tractor tires 9.5-24 |

| Overall Dimension | 5800 mm x 2900 mm x 3700 mm | Rear Tire Product | Tractor tires 9.5-24 |

| Weight | 3811Kg | Water Tank | 15L |

Q:Are you a manufacturing unit or investing business?

A:We are a manufacturing unit.

Q: How does your factory do relating to good quality handle?

A: Quality is precedence. we usually say great importance to top quality managing from the very starting to the very conclude.

Q: Do you have a merchandise accessory?

A: Yes, we have the add-ons of the product.

Q:Can you customise the merchandise?

A:We can customize the merchandise.

Q: What’s your payment terms?

A: Payment terms is T/T or L/C,We accept all reasonable payment.

Q: How about delivery time of your machine?

A: The delivery time is in 60 working days. It depending your quantity.

Best made in China – replacement parts – Chain & sprocket manufacturer : 3325-9059f1 roller chain power transmission in Panama City Panama 3300-27150 3330-28361 3330-3852 3330-66402f1 3330-66402f2 3330-74311 3330-74311f1 Rice Harvester Chains of Agricultural Machinery with ce certificate top quality low price

We – EPG Team the greatest Chain and agricultural gearbox manufacturing facility in China with 5 diverse branches. For a lot more particulars: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

With several years’ expertise in these strains, we have been distinguished from other suppliers in China by our positive aspects in aggressive pricing, on-time delivery, prompt responses, on-hand engineering assistance and excellent following-product sales companies. EPG If you need any info or samples, please speak to us and you will have our shortly reply.energy transmission goods are created to provide each reliable functionality and cost-performance. Every single item is utility-analyzed and engineered to meet stringent specifications for uniformity in dimension, heat remedy, tensile power and other essential characteristics. As a price-effective different developed exclusively for general-duty use, EPG’s growing line of products are accessible in all regularly requested sizes and specifications, such as ball bearings, mounted models, roller chain, seals, gauges, sheaves and much more. The continued expansion of our ball bearings, mounted models and electricity transmission solution lines, together with our attention to depth and top quality, has authorized EPG to gain wide acceptance to a various consumer base. 3325-9059F1 3300-27150 3330-28361 3330-3852 3330-66402F1 3330-66402F2 3330-74311 3330-74311F1 Rice Harvester Chains Of Agricultural Machinery

Solution Description

Walking Tractor chain: 08B-2 12A-2 12AH-2

Blend chain: 08B1,08B3,10A1,10A2,12A1,16A1,16AH1,ZGS38 and attachment.

S-variety Metal Agricultural chain: S32,S42,S45,S52,S55,S62,S77,S88 and with K1,F1,SD,C6E attachment.

A-sort metal Agricultural chain: A550,A555,A557,A620 and with attachment.

CA-kind steel agricultural chain:CA550, CA555,CA557,CA620,CA2060H,38.4R,38.4V,CA39,CA624 and attachment.

Business Info

EPT Industry co.,Ltd is a specialized and OEM supplier of a total assortment of chains, sprockets, coupling, timing pulley, v belt pulley, shaft, gear, gear rack and EPT transmission spare parts.

Due to our sincerity in working with clients, comprehension of their requirements and overriding perception of accountability toward filling ordering demands, we have attained the tru EPT of buyer’s throughout the world. Getting amassed cherished experience in cooperating with international consumers, our EPT brand merchandise are promoting nicely in the American, European, South American and Asian marketplaces. Our EPT model merchandise are made by modern day computerized machinery and tools. In the meantime, these are created according to high top quality stHangZhourds, and complying with the intercontinental sophisticated stHangZhourd criteria.

With numerous year’s knowledge in this line, we will tru EPT by our positive aspects in competitive pricing, on-time delivery, prompt responses,on-hand engineering support and excellent soon after-sales services. In addition, all our generation methods are in compliance with ISO9002 stHangZhourds. We also can layout and make non-stHangZhourd merchandise to fulfill customers’ specific necessity. Top quality and credit history are the bases that make a corporation alive. We will provide be EPT providers and large quality items with all sincerity. If you want any details or samples, you should speak to us and you will have our before long reply. Looking ahead to cooperate with you for prolonged phrase!

The use of first products manufacturer’s (OEM) part figures or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our organization and the outlined substitute parts contained herein are not sponsored, accepted, or manufactured by the OEM.

Best China manufacturer & factory Agricultural in Taizhong China, Taiwan Province of China pto shaft Machinery New Series 8 Heavy Duty Italian Type 540 tractor Pto Drive Shaft With high quality best price

With several years’ knowledge in these traces, we have been distinguished from other suppliers in China by our benefits in aggressive pricing, on-time delivery, prompt responses, on-hand engineering help and great after-product sales solutions.

Overview

Rapid Particulars

- Issue:

-

New

- Warranty:

-

one.5 a long time

-

Adhering to “Survival by Good quality, Growth by Engineering & Credit rating”, The organization will constantly boost merchandise overall performance to satisfy the increasing consumer demands in the demanding type of work.

- Relevant Industries:

-

Production Plant, Pto Push Shaft

- Soon after Warranty SBREATHER Design and style Although there are dozens of stock breathers and vent plugs on the market, EPT screening located none to be entirely successful under all running problems. Variables such as input/output speed, route of rotation, oil level and viscosity, and reducer mounting position all impact breather efficiency.ervice:

-

On the internet assistance

- Regional Service Area:

-

none, Italy

- Showroom Place:

-

ITALY

- Online video outgoing-inspection:

-

Supplied

- Equipment Examination Report:

-

Offered

- Advertising Kind:

-

New Product 2020

- Sort:

-

Shafts

- Use:

-

tractors

- Area of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- certification:

-

CE

- Substance:

-

Metal

- Coloration:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Chilly drawn

- Style:

-

Tailored

- Certificate:

-

CE Certification

Supply Capability

- Supply Capacity:

- 20000 Piece/Items for every Thirty day period

Packaging & Shipping

- Packaging Particulars

- Packing specifics:Iron pallet&picket carton&common export packaging

- Port

- ningbo or shanghai

-

Lead Time

: -

Quantity(Parts) 1 – 9999 >9999 Est. Time(times) twelve To be negotiated

Online Customization

Relevant solution

Firm Profile

Packing & Supply

Our PTO drive shafts enable the consumer straightforward servicing. The greasing nipples on normal crosses are positioned under angle to empower the consumer greater access. Simpler access is also feasible because of the adaptable cone. We listened to the wishes of our buyers and put the greasing nipple at vast-angle PTO’s into the cross bearing. The other novelty, we introduced with wide-angle PTO drive shafts is in line greasing. We needed to moreover simplify the maintenance and increase the lifespan of joints.

Quick China Delivery Heavy Duty Tractor Parts Agricultural Machinery – Supplier Manufacturer wholesaler Factory

For far more information.: Cellular/Whatpp: +8613083988828

How Can You Be Protected When Using PTO Shafts? First, make certain the shaft is shielded. This involves the driveline protect that addresses the implement driveline, and the grasp shield which handles the universal joint and PTO stub shaft on the tractor.Maintain the protect so it can work for you. PTO driveline shields are typically mounted on bearings, so they need to have to be maintained. always REPLACE the protect when it is destroyed or missing.Following, keep a safe length from it when in use. Preserve others absent, way too. How considerably? A distance of 2 times your peak is a great start off.Allow only these who totally must be in the location to be there. Hold all young children away!Always shell out attention to what is taking place. Most PTO victims have been caught by shock.If one thing goes mistaken — end the equipment take the PTO out of equipment, stop the engine and established the brake. Place the keys in your pocket before operating on the equipment.When stopping the machinery for any reason — stop of perform, lunch, repairs, or communication — just take the PTO out of equipment, stop the motor and established the brake.Highway planers, dredges, and other products need power from some form of engine in buy to execute their created perform. Without a energy get off, it would be essential to include a next motor to give the energy needed to run hydraulic pumps and other driveline hooked up tools.Established in the year 1997, we “EPG” are a trustworthy and famous Manufacturer of a wide assortment of Thresher Equipment, Thresher Gearbox and Chaff Cutters. We are a Proprietor company, which is situated in HangZhou. We provide these products in assorted specifications to achieve the full fulfillment of the clients. Additional, our sturdy logistic assist can make sure that these goods are delivered inside the promised time-body. Under the supervision of “Mr.Shen” (Proprietor), we have obtained massive clientele in our place.In 2008, it was awarded with “National Export Commodity Inspection-cost-free Enterprise”. EPG is specialized in design and style, company and revenue of agricultural equipment and farm implements, which has an independent import and export rights.

Overview

Swift Specifics

- Warranty:

-

1.5 many years

- Applicable Industries:

-

Production Plant

- After Guarantee Provider:

-

Online assistance

- Neighborhood Service Place:

-

None, Italy

- Showroom Area:

-

Italy

- Kind:

-

Shafts

- Area of Origin:Zhejiang, China

- Model Identify:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Colour:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Chilly drawn

- Design:

-

Customized

- Certificate:

-

CE Certification

Supply Capability

- Offer Ability:

- 20000 Piece/Parts for each Thirty day period

Packaging & Delivery

- Packaging Information

- Packing information:Iron pallet&wooden carton&common export packaging

- Port

- ningbo or shanghai

On-line Customization

Merchandise Information

Solution Details

PTO Shaft

The electricity just take-off (PTO) is a advanced system, permitting implements to attract power from the motor and transmit it to yet another software. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The electrical power take-off shaft (PTO shaft) is a vital component, developed and made for ongoing weighty-duty use. A good PTO shaft must be robust adequate to bear the torsion and shear stress and decrease vibration.

Setforge, the forging subsidiary of Ever-Electricity Group, manufactures cold extruded PTO shafts for all kinds of agriculture automobiles. Our PTO shafts supply excellent dependability and durability in the course of every day use.

EP Group has been internationally recognized as a reliable worldwide provider. Our state-of-the-artwork manufacturing method and knowledgeable engineers make certain the best-top quality of all Farinia factors.

| Soon after Guarantee Support | Movie specialized help |

| Relevant Industries | Production Plant |

| Neighborhood Support Location | Italy |

| Showroom Area | Italy |

| Warranty | 1.five years |

| Variety | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Manufacturer Name | EPG |

| certification | CE |

| Materials | Steel |

| Shade | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Chilly drawn |

| Design and style | Tailored |

| Certificate | CE Certificate |

Product Display

Solution Screen

PTO Drive Line Gen …

CAT 3 Swift Hitch

6″ Large Obligation Eart …

CompanyInfo

Company Profile

At any time-Electrical power Team

EPG have large-tech machinery and check tools. We can produce world course substantial precision goods.

Certifications

Certifications

Shipment & Payment

Our Benefits

A: Your inquiry relevant to our merchandise or costs will be replied in 24 several hours.

B: Security of your product sales region, suggestions of design and style and all your non-public info.

C: Best quality and aggressive value.

……

faq

FAQ

one) How can I area order?

A: You can get in touch with us by electronic mail about your purchase information, or spot get on line.

2) How can I shell out you?

A: After you verify our PI, we will request you to shell out. T/T (HSBC financial institution) and Paypal, Western Union are the most typical approaches we are utilizing.

……

EPG – 1 of the greatest transmission manufacturing unit in China, principal merchandise: worm geared motors, agricultrual gearbox, planetary gear drive, helical,screw, beve gears and spare components and agricultural elements manunfacuter in China /For a lot more info.: Mobile/Whatpp: +8613083988828