Product Description

Product Description

Driveline Adapter Cardan Shaft for Farm Equipment Pto Shaft and Tractor Pto Drive Shaft

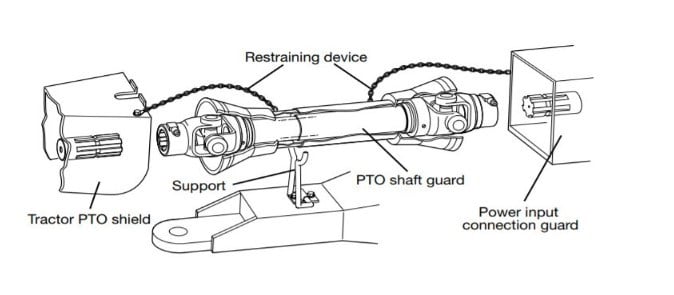

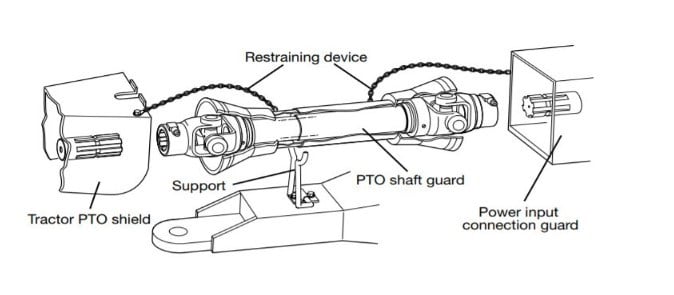

A Power Take-Off shaft (PTO shaft) is a mechanical device utilized to transmit power from a tractor or other power source to an attached implement, such as a mower, tiller, or baler. Typically situated at the rear of the tractor, the PTO shaft is driven by the tractor’s engine through the transmission.

The primary purpose of the PTO shaft is to supply a rotating power source to the implement, enabling it to carry out its intended function. To connect the implement to the PTO shaft, a universal joint is employed, allowing for movement between the tractor and the implement while maintaining a consistent power transfer.

Here is our advantages when compare to similar products from China:

1.Forged yokes make PTO shafts strong enough for usage and working;

2.Internal sizes standard to confirm installation smooth;

3.CE and ISO certificates to guarantee to quality of our goods;

4.Strong and professional package to confirm the good situation when you receive the goods.

Product Specifications

In farming, the most common way to transmit power from a tractor to an implement is by a driveline, connected to the PTO (Power Take Off) of the tractor to the IIC(Implement Input Connection). Drivelines are also commonly connected to shafts within the implement to transmit power to various mechanisms.

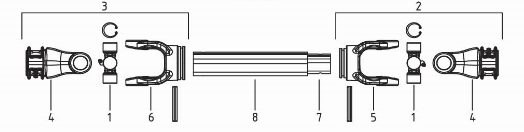

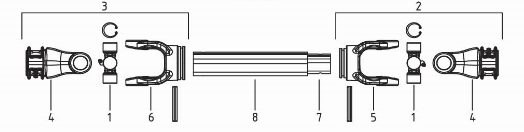

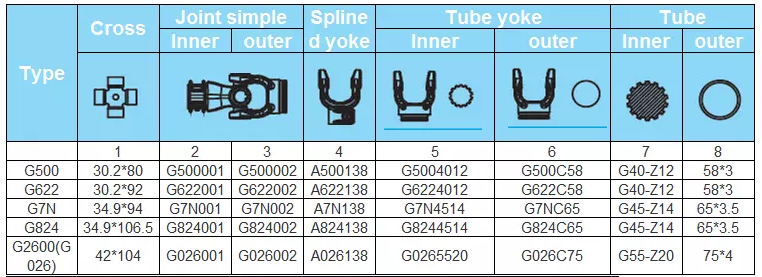

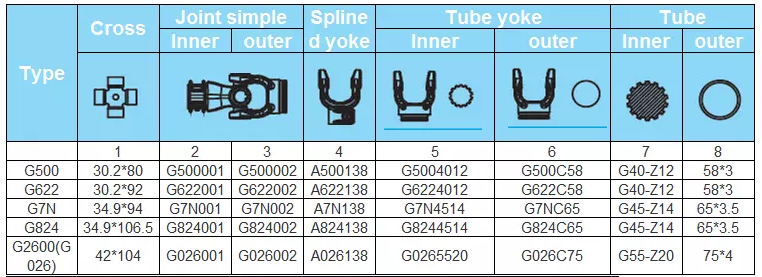

The following dimensions of the PTO types are available.

Type B:13/8″Z6(540 min)

Type D:13/8″Z21(1000 min)

Coupling a driveline to a PTO should be quick and simple because in normal use tractors must operate multiple implements. Consequently, yokes on the tractor-end of the driveline are fitted with a quick-disconnect system, such as push-pin or ball collar.

Specifications for a driveline, including the way it is coupled to a PTO, depend CZPT the implement.

Yokes on the llc side are rarely disconnected and may be fastened by quick-lock couplings (push-pin or ball collar).

Taper pins are the most stable connection for splined shafts and are commonly used in yokes and torque limiters. Taper pins are also often used to connect internal drive shafts on drivelines that are not frequently disconnected.

Torque limiter and clutches must always be installed on the implement side of the primary driveline.

Packaging & Shipping

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of ” High Quality, Customers’Satisfaction”, using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

1.WHAT’S THE PAYMENT TERM?

When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

2.HOW TO DELIVER THE GOODS TO US?

Usually we will ship the goods to you by sea.

3.How long is your delivery time and shipment?

30-45days

| Type: | Pto Shaft |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery,Farm Tractor |

| Material: | 45cr Steel |

| Power Source: | Pto Dirven Shaft |

| Weight: | 8-15kg |

| After-sales Service: | Online Support |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do manufacturers ensure the compatibility of drive shafts with different equipment?

Manufacturers employ various strategies and processes to ensure the compatibility of drive shafts with different equipment. Compatibility refers to the ability of a drive shaft to effectively integrate and function within a specific piece of equipment or machinery. Manufacturers take into account several factors to ensure compatibility, including dimensional requirements, torque capacity, operating conditions, and specific application needs. Here’s a detailed explanation of how manufacturers ensure the compatibility of drive shafts:

1. Application Analysis:

Manufacturers begin by conducting a thorough analysis of the intended application and equipment requirements. This analysis involves understanding the specific torque and speed demands, operating conditions (such as temperature, vibration levels, and environmental factors), and any unique characteristics or constraints of the equipment. By gaining a comprehensive understanding of the application, manufacturers can tailor the design and specifications of the drive shaft to ensure compatibility.

2. Customization and Design:

Manufacturers often offer customization options to adapt drive shafts to different equipment. This customization involves tailoring the dimensions, materials, joint configurations, and other parameters to match the specific requirements of the equipment. By working closely with the equipment manufacturer or end-user, manufacturers can design drive shafts that align with the equipment’s mechanical interfaces, mounting points, available space, and other constraints. Customization ensures that the drive shaft fits seamlessly into the equipment, promoting compatibility and optimal performance.

3. Torque and Power Capacity:

Drive shaft manufacturers carefully determine the torque and power capacity of their products to ensure compatibility with different equipment. They consider factors such as the maximum torque requirements of the equipment, the expected operating conditions, and the safety margins necessary to withstand transient loads. By engineering drive shafts with appropriate torque ratings and power capacities, manufacturers ensure that the shaft can handle the demands of the equipment without experiencing premature failure or performance issues.

4. Material Selection:

Manufacturers choose materials for drive shafts based on the specific needs of different equipment. Factors such as torque capacity, operating temperature, corrosion resistance, and weight requirements influence material selection. Drive shafts may be made from various materials, including steel, aluminum alloys, or specialized composites, to provide the necessary strength, durability, and performance characteristics. The selected materials ensure compatibility with the equipment’s operating conditions, load requirements, and other environmental factors.

5. Joint Configurations:

Drive shafts incorporate joint configurations, such as universal joints (U-joints) or constant velocity (CV) joints, to accommodate different equipment needs. Manufacturers select and design the appropriate joint configuration based on factors such as operating angles, misalignment tolerances, and the desired level of smooth power transmission. The choice of joint configuration ensures that the drive shaft can effectively transmit power and accommodate the range of motion required by the equipment, promoting compatibility and reliable operation.

6. Quality Control and Testing:

Manufacturers implement stringent quality control processes and testing procedures to verify the compatibility of drive shafts with different equipment. These processes involve conducting dimensional inspections, material testing, torque and stress analysis, and performance testing under simulated operating conditions. By subjecting drive shafts to rigorous quality control measures, manufacturers can ensure that they meet the required specifications and performance criteria, guaranteeing compatibility with the intended equipment.

7. Compliance with Standards:

Manufacturers ensure that their drive shafts comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, provides assurance of quality, safety, and compatibility. Adhering to these standards helps manufacturers meet the expectations and requirements of equipment manufacturers and end-users, ensuring that the drive shafts are compatible and can be seamlessly integrated into different equipment.

8. Collaboration and Feedback:

Manufacturers often collaborate closely with equipment manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft design and manufacturing processes. This collaborative approach ensures that the drive shafts are compatible with the intended equipment and meet the expectations of the end-users. By actively seeking input and feedback, manufacturers can continuously improve their products’ compatibility and performance.

In summary, manufacturers ensure the compatibility of drive shafts with different equipment through a combination of application analysis, customization, torque and power capacity considerations, material selection, joint configurations, quality control and testing, compliance with standards, and collaboration with equipment manufacturers and end-users. These efforts enable manufacturers to design and produce drive shafts that seamlessly integrate with various equipment, ensuring optimal performance, reliability, and compatibility in different applications.

How do drive shafts handle variations in load and vibration during operation?

Drive shafts are designed to handle variations in load and vibration during operation by employing various mechanisms and features. These mechanisms help ensure smooth power transmission, minimize vibrations, and maintain the structural integrity of the drive shaft. Here’s a detailed explanation of how drive shafts handle load and vibration variations:

1. Material Selection and Design:

Drive shafts are typically made from materials with high strength and stiffness, such as steel alloys or composite materials. The material selection and design take into account the anticipated loads and operating conditions of the application. By using appropriate materials and optimizing the design, drive shafts can withstand the expected variations in load without experiencing excessive deflection or deformation.

2. Torque Capacity:

Drive shafts are designed with a specific torque capacity that corresponds to the expected loads. The torque capacity takes into account factors such as the power output of the driving source and the torque requirements of the driven components. By selecting a drive shaft with sufficient torque capacity, variations in load can be accommodated without exceeding the drive shaft’s limits and risking failure or damage.

3. Dynamic Balancing:

During the manufacturing process, drive shafts can undergo dynamic balancing. Imbalances in the drive shaft can result in vibrations during operation. Through the balancing process, weights are strategically added or removed to ensure that the drive shaft spins evenly and minimizes vibrations. Dynamic balancing helps to mitigate the effects of load variations and reduces the potential for excessive vibrations in the drive shaft.

4. Dampers and Vibration Control:

Drive shafts can incorporate dampers or vibration control mechanisms to further minimize vibrations. These devices are typically designed to absorb or dissipate vibrations that may arise from load variations or other factors. Dampers can be in the form of torsional dampers, rubber isolators, or other vibration-absorbing elements strategically placed along the drive shaft. By managing and attenuating vibrations, drive shafts ensure smooth operation and enhance overall system performance.

5. CV Joints:

Constant Velocity (CV) joints are often used in drive shafts to accommodate variations in operating angles and to maintain a constant speed. CV joints allow the drive shaft to transmit power even when the driving and driven components are at different angles. By accommodating variations in operating angles, CV joints help minimize the impact of load variations and reduce potential vibrations that may arise from changes in the driveline geometry.

6. Lubrication and Maintenance:

Proper lubrication and regular maintenance are essential for drive shafts to handle load and vibration variations effectively. Lubrication helps reduce friction between moving parts, minimizing wear and heat generation. Regular maintenance, including inspection and lubrication of joints, ensures that the drive shaft remains in optimal condition, reducing the risk of failure or performance degradation due to load variations.

7. Structural Rigidity:

Drive shafts are designed to have sufficient structural rigidity to resist bending and torsional forces. This rigidity helps maintain the integrity of the drive shaft when subjected to load variations. By minimizing deflection and maintaining structural integrity, the drive shaft can effectively transmit power and handle variations in load without compromising performance or introducing excessive vibrations.

8. Control Systems and Feedback:

In some applications, drive shafts may be equipped with control systems that actively monitor and adjust parameters such as torque, speed, and vibration. These control systems use sensors and feedback mechanisms to detect variations in load or vibrations and make real-time adjustments to optimize performance. By actively managing load variations and vibrations, drive shafts can adapt to changing operating conditions and maintain smooth operation.

In summary, drive shafts handle variations in load and vibration during operation through careful material selection and design, torque capacity considerations, dynamic balancing, integration of dampers and vibration control mechanisms, utilization of CV joints, proper lubrication and maintenance, structural rigidity, and, in some cases, control systems and feedback mechanisms. By incorporating these features and mechanisms, drive shafts ensure reliable and efficient power transmission while minimizing the impact of load variations and vibrations on overall system performance.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2023-11-14

Best China manufacturer & factory Agricultural in Taizhong China, Taiwan Province of China pto shaft Machinery New Series 8 Heavy Duty Italian Type 540 tractor Pto Drive Shaft With high quality best price

With several years’ knowledge in these traces, we have been distinguished from other suppliers in China by our benefits in aggressive pricing, on-time delivery, prompt responses, on-hand engineering help and great after-product sales solutions.

Overview

Rapid Particulars

- Issue:

-

New

- Warranty:

-

one.5 a long time

-

Adhering to “Survival by Good quality, Growth by Engineering & Credit rating”, The organization will constantly boost merchandise overall performance to satisfy the increasing consumer demands in the demanding type of work.

- Relevant Industries:

-

Production Plant, Pto Push Shaft

- Soon after Warranty SBREATHER Design and style Although there are dozens of stock breathers and vent plugs on the market, EPT screening located none to be entirely successful under all running problems. Variables such as input/output speed, route of rotation, oil level and viscosity, and reducer mounting position all impact breather efficiency.ervice:

-

On the internet assistance

- Regional Service Area:

-

none, Italy

- Showroom Place:

-

ITALY

- Online video outgoing-inspection:

-

Supplied

- Equipment Examination Report:

-

Offered

- Advertising Kind:

-

New Product 2020

- Sort:

-

Shafts

- Use:

-

tractors

- Area of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- certification:

-

CE

- Substance:

-

Metal

- Coloration:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Chilly drawn

- Style:

-

Tailored

- Certificate:

-

CE Certification

Supply Capability

- Supply Capacity:

- 20000 Piece/Items for every Thirty day period

Packaging & Shipping

- Packaging Particulars

- Packing specifics:Iron pallet&picket carton&common export packaging

- Port

- ningbo or shanghai

-

Lead Time

: -

Quantity(Parts) 1 – 9999 >9999 Est. Time(times) twelve To be negotiated

Online Customization

Relevant solution

Firm Profile

Packing & Supply

Our PTO drive shafts enable the consumer straightforward servicing. The greasing nipples on normal crosses are positioned under angle to empower the consumer greater access. Simpler access is also feasible because of the adaptable cone. We listened to the wishes of our buyers and put the greasing nipple at vast-angle PTO’s into the cross bearing. The other novelty, we introduced with wide-angle PTO drive shafts is in line greasing. We needed to moreover simplify the maintenance and increase the lifespan of joints.

Anon China pto spline adapter Agricultural Machinery 30-50 HP Farm Diesel Walking Mini Tractor with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto factory in China with 5 different branches. For more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

With higher good quality regular straight line, h2o cooling, 4 stroke, direct injection EPT engine, imported gas injection technique, minimal gasoline intake and f EPT pace, can attain big torque output beneath bad circumstances (much more than thirty% torque reserve ratio), durable and reputable.

The maximum velocity can attain 32km/h, and the subject transfer and transportation procedure has much more positive aspects, which can efficiently reduce the load time and enhance the procedure efficiency.

Equipped with 70L large ability rotary oil tank, it can be easily refueling and can satisfy the demands of steady procedure for far more than 10 hours.

The f EPT shift of EPT and backwards can be realized by adopting the shuttle equipment shifting composition and when hanging. It has twelve ahead gears and 12 backward gears, and has a lot of matching speeds. It can decide on the greatest operation speed in accordance to different equipment and various soil resistance.

Entirely think about the various planting specifications and operating ridges of customers. Optional wheelset stepless adju EPT unit (1.three-one.8m), broad assortment of wheelsets, no ridge and seedling strain during procedure.

The dual speed mix of power output can meet up with the demands of a variety of devices for speed, adju EPT traction, guaranteeing that electrical power output and traction can be utilized at the very same time, with out disturbing every other.

The horizontal sturdy stress raise is marked with a massive lifting pressure. The optional position is independently altered to raise, imported technological innovation and dependable overall performance.

Adopting a new kind of integral type completely sealed front axle, the driving shaft power is improved and tough, which is the initial option for paddy subject operation.

Geared up with air conditioned taxi, isolation and seem insulation, and massive annular visible discipline, all temperature operations can be realized. The taxi has great sealing efficiency, and filth, filth and other debris are not effortless to enter the cab throughout operation, so that the functioning atmosphere is thoroughly clean and relaxed.

Making use of facet placing, flat floor and suspension pedal, the distribution of management structure is reasonable, the driving place is massive, the comfort of operation is enhanced, and the driver’s working toughness is decreased.

| Product | 304 | 404 | 504 | 0571 |

| Horse electricity/Generate Kind | 30hp,4X4 | 40hp,4X4 | 50hp,4X4 | 60hp,4X4 |

| Motor | Lai EPT Three Engine/ EPT Three Engine | |||

| Kind | Vertical,water-cooled,4 Strokes,Immediate in Injection | |||

| Rated Output(KW) | 23.6 | 29.four | 36.eight | forty.4 |

| Dimension(mm) | 3050X1320X2050 | |||

| Wheel Foundation(mm) | 1700 | 1850 | 1900 | 1900 |

| Wheel Thread F/R(mm) | 1060/1080 | |||

| Mini Floor Clearance(mm) | 280 | |||

| Gear Shift | 8F+2R | |||

| Cluth Kind | Dry Single-phase | |||

| Tire F/R | 600-sixteen/nine.fifty-24 | 600-sixteen/9.fifty-24 | 650-sixteen/eleven.two-24 | 650-16/eleven.2-24 |

| Steering | Hydraulic Steering | |||

| Brake | Toe Sort | |||

| Park Brake | Latch Pedal | |||

| Hitch | Partial Divided,three-level Hydraulic hitch,Class I | |||

| Max. Carry Force(N) | ≥ 0571 | ≥6950 | ≥6300 | ≥6300 |

| Rear PTO | Rear Rectangle Spline,six Enamel,720rpm | Rear Rectangle Spline,6 Enamel,540/720rpm | ||

Quick China Delivery Heavy Duty Tractor Parts Agricultural Machinery – Supplier Manufacturer wholesaler Factory

For far more information.: Cellular/Whatpp: +8613083988828

How Can You Be Protected When Using PTO Shafts? First, make certain the shaft is shielded. This involves the driveline protect that addresses the implement driveline, and the grasp shield which handles the universal joint and PTO stub shaft on the tractor.Maintain the protect so it can work for you. PTO driveline shields are typically mounted on bearings, so they need to have to be maintained. always REPLACE the protect when it is destroyed or missing.Following, keep a safe length from it when in use. Preserve others absent, way too. How considerably? A distance of 2 times your peak is a great start off.Allow only these who totally must be in the location to be there. Hold all young children away!Always shell out attention to what is taking place. Most PTO victims have been caught by shock.If one thing goes mistaken — end the equipment take the PTO out of equipment, stop the engine and established the brake. Place the keys in your pocket before operating on the equipment.When stopping the machinery for any reason — stop of perform, lunch, repairs, or communication — just take the PTO out of equipment, stop the motor and established the brake.Highway planers, dredges, and other products need power from some form of engine in buy to execute their created perform. Without a energy get off, it would be essential to include a next motor to give the energy needed to run hydraulic pumps and other driveline hooked up tools.Established in the year 1997, we “EPG” are a trustworthy and famous Manufacturer of a wide assortment of Thresher Equipment, Thresher Gearbox and Chaff Cutters. We are a Proprietor company, which is situated in HangZhou. We provide these products in assorted specifications to achieve the full fulfillment of the clients. Additional, our sturdy logistic assist can make sure that these goods are delivered inside the promised time-body. Under the supervision of “Mr.Shen” (Proprietor), we have obtained massive clientele in our place.In 2008, it was awarded with “National Export Commodity Inspection-cost-free Enterprise”. EPG is specialized in design and style, company and revenue of agricultural equipment and farm implements, which has an independent import and export rights.

Overview

Swift Specifics

- Warranty:

-

1.5 many years

- Applicable Industries:

-

Production Plant

- After Guarantee Provider:

-

Online assistance

- Neighborhood Service Place:

-

None, Italy

- Showroom Area:

-

Italy

- Kind:

-

Shafts

- Area of Origin:Zhejiang, China

- Model Identify:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Colour:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Chilly drawn

- Design:

-

Customized

- Certificate:

-

CE Certification

Supply Capability

- Offer Ability:

- 20000 Piece/Parts for each Thirty day period

Packaging & Delivery

- Packaging Information

- Packing information:Iron pallet&wooden carton&common export packaging

- Port

- ningbo or shanghai

On-line Customization

Merchandise Information

Solution Details

PTO Shaft

The electricity just take-off (PTO) is a advanced system, permitting implements to attract power from the motor and transmit it to yet another software. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The electrical power take-off shaft (PTO shaft) is a vital component, developed and made for ongoing weighty-duty use. A good PTO shaft must be robust adequate to bear the torsion and shear stress and decrease vibration.

Setforge, the forging subsidiary of Ever-Electricity Group, manufactures cold extruded PTO shafts for all kinds of agriculture automobiles. Our PTO shafts supply excellent dependability and durability in the course of every day use.

EP Group has been internationally recognized as a reliable worldwide provider. Our state-of-the-artwork manufacturing method and knowledgeable engineers make certain the best-top quality of all Farinia factors.

| Soon after Guarantee Support | Movie specialized help |

| Relevant Industries | Production Plant |

| Neighborhood Support Location | Italy |

| Showroom Area | Italy |

| Warranty | 1.five years |

| Variety | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Manufacturer Name | EPG |

| certification | CE |

| Materials | Steel |

| Shade | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Chilly drawn |

| Design and style | Tailored |

| Certificate | CE Certificate |

Product Display

Solution Screen

PTO Drive Line Gen …

CAT 3 Swift Hitch

6″ Large Obligation Eart …

CompanyInfo

Company Profile

At any time-Electrical power Team

EPG have large-tech machinery and check tools. We can produce world course substantial precision goods.

Certifications

Certifications

Shipment & Payment

Our Benefits

A: Your inquiry relevant to our merchandise or costs will be replied in 24 several hours.

B: Security of your product sales region, suggestions of design and style and all your non-public info.

C: Best quality and aggressive value.

……

faq

FAQ

one) How can I area order?

A: You can get in touch with us by electronic mail about your purchase information, or spot get on line.

2) How can I shell out you?

A: After you verify our PI, we will request you to shell out. T/T (HSBC financial institution) and Paypal, Western Union are the most typical approaches we are utilizing.

……

EPG – 1 of the greatest transmission manufacturing unit in China, principal merchandise: worm geared motors, agricultrual gearbox, planetary gear drive, helical,screw, beve gears and spare components and agricultural elements manunfacuter in China /For a lot more info.: Mobile/Whatpp: +8613083988828