Product Description

Product Description

Introduction of Commodity

Cold drawn steel is a kind of steel processed by cold drawing process. It has high strength and hardness and is widely used in various fields.

Cold drawn steel has high strength and hardness, is widely used in machinery manufacturing, automobile industry, electronic and electrical, aerospace and construction fields.Cold drawn steel is processed by cold drawing process, which has good mechanical properties and surface quality. It can meet the requirements of material strength, durability and accuracy in different fields, and provides a reliable material basis for all walks of life.

Product Parameters

| Product name | Cold drawn steel stainless bright precision bars | |

| Material | 304,304L,309S,310S,316,316L,316Ti,317,317L,321,347H,201,202,405,409, | |

| 410,420,430,etc | ||

| Type | Round, square, hexagonal, flat,angle | |

| Surface | Bright, Polishing | |

| Specification | Round bar | Diameter: 1mm~500mm |

| Angle bar | Size: 3mm*20mm*20mm~12mm*100mm*100mm | |

| Square bar | Size: 4mm*4mm~100mm*100mm | |

| Flat bar | Thickness: 2mm~100mm Width: 10mm~500mm | |

| Hexagonal | Size: 2mm~100mm | |

| Shape | Round/Square/Rectangular or Customized | |

| Technical | Cold Drawn | |

| Color | Silver White | |

| Origin | ZheJiang , China | |

| Surface Treatment | Polished | |

| Price Term | CIF, CFR, Fob, EXW | |

| Transportation | FCL, LCL | |

| Certificate | API,ISO,SGS,BV,CE etc | |

| Delivery Time | 7-14days | |

| Warranty | 1 year | |

| MOQ | 1000 kilograms | |

| Payment Item | 30% TT deposit+70% TT against copies of original files. | |

| Application | Manufacturing industry, Architectural decoration, furniture, Chemical industry, Electronics industry, Medical devices, Environmental protection field etc. | |

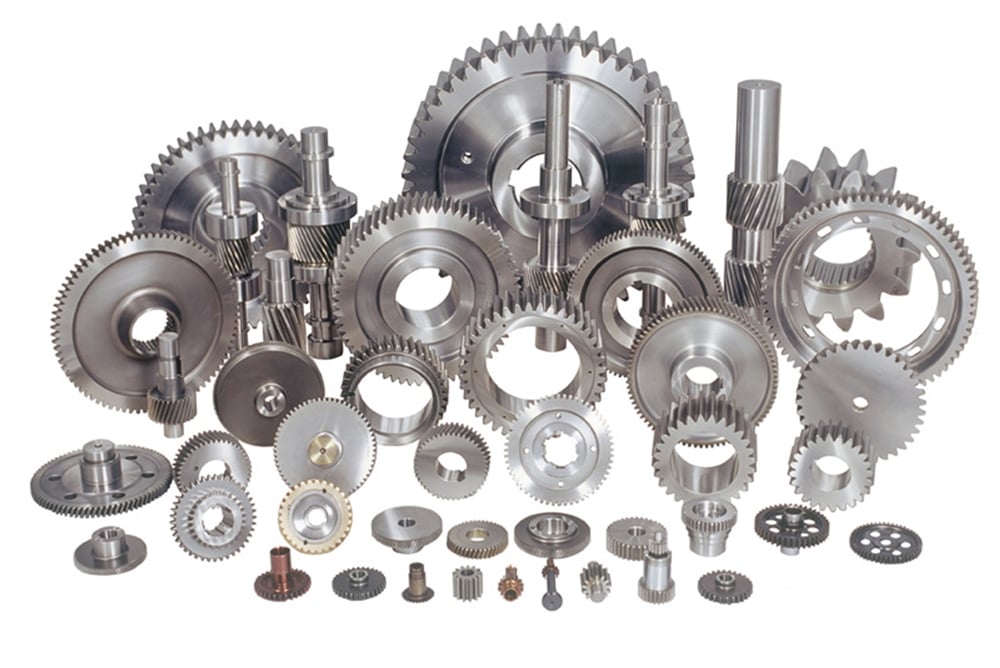

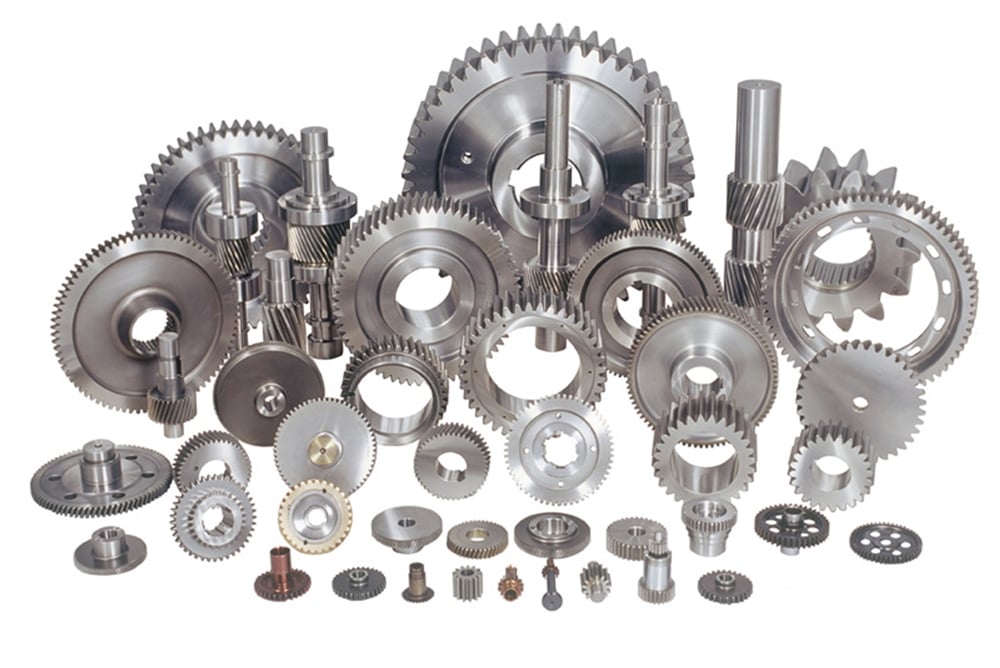

Products Display

Company Profile

Xinruyi Steel Group was built in year 2017 with registered capital of 30,000,000RMB, and we have been in the steel products industries for more than 10years. The group is located in HangZhou City, next to capital of ZheJiang Province, and it enjoy good transportation environment of 3 hours to nearest port and 1 hour CZPT the airport.

As it is well known to all, HangZhou city is the biggest steel pipe base in North China, with this significant advantage on geography aspect, us company have developed into 1 modern international CZPT STEEL GROUP. Till now we have 2 production plants for steel pipes and plate series production and processing, and 3 warehouses for steel products. Our yearly production scale can be reach to 500,000tons, and our warehouse stocks is yearly above 20,000tons. So that we can meet all kinds of demands from different countries clients. Our salesmen are trained to get the best and professional skills on doing export trading dealing with various kinds of issues in the trading, which is a base that our buyers can have good buying experience. Till now we can supply the good quality products consisting of and not limit to the following, steel pipes, bars, rock bolts, guardrail composite pipe, guardrail board, color coated steel coils, galvanized coils, steel balls, steel chains, steel plates and steel bearing. Besides we can provides processing procedures for the steel products, like anti-rust protecting, cutting and chamfer, coupling, heat treating, bending, galvanizing, polishing, beveling, pickling, plastic spraying, CNC machining, and so on.

With efforts of CZPT People we have the pleasure to serve the clients from more than 20 countries and areas, We earned good reputations from the clients without any claim. We finally become good friends and intimate partners with them.

Looking forward, we get good confidence that we will expand our business scales to more countries and areas, and serve more people in the world. Because we always believe quality of the commodity is the life of company, stability is the essence of quality. Also the integrity in business will help bring the long term business relationship, so it is the code that 1 company can develop and survive.

Xinruyi Group is looking CZPT to the cooperation with you! We believe 1 time cooperation, friends forever!

(Xinruyi Steel Group Swear: we do not cheat any of our client, we only do business with good faith and honesty! CZPT will NEVER offering incredible low rate to attract clients and sending less weight goods to make money. )

(Xinruyi Steel Group Swear: Even if we do not get the order, we do not cheat even 1 client!)

(We give Made-in-China complain center as below: complaint/)

Insepction And Testing

Featured Products

Certifications

*What is your paying terms?

Our usual paying terms are 30%TT as deposit and balance paid after seeing copy of bill of loading. For clients cooperated for more than 1 year, we accept 20% prepay. Beside we do business also under D/P and LC terms.

*How long is your delivery time?

For the goods we have in stocks, we deliver the goods within 5days. If it is a production order with volume not above 200tons, the delivery time will usually be within 20days after sealing contract. And the delivery time shall be slightly longer for order volume above 200tons.

*Can you do partial shipment?

We will follow client request to do partial shipment or not. Partial shipment is not a problem for us.

*What is your Minimum Order Quantity?

For goods in stocks we supply starting with 1 piece. Shall it is a production order, the MOQ is 3tons. Please be noted price based on MOQ will be slight higher than FCL condition due to higher unit cost.

*Before cooperation we want a sample for inspecting of quality, is that okay?

We can provide a free sample for you shall sample value not above 30USD, you only need to pay the express charge. For a sample valued more than 30USD, the express charge and just 1 half of sample value is on the account of you, and we afford the other half.

*What is the mode of transportation?

Ocean freight is the most important shipping way, and we choose the ship line based on soonest and earliest shipping time, rather than cheaper cost; or we follow clients’ instruction if there is one. Also railways will be chosen by us when it is more convenient. For samples and papers, the transportation will be by air.

FAQ

1.What is your paying terms?

Our usual paying terms are 30%TT as deposit and balance paid after seeing copy of bill of loading. For clients cooperated for more than 1 year, we accept 20% prepay. Beside we do business also under D/P and LC terms.

2.How long is your delivery time?

For the goods we have in stocks, we deliver the goods within 5days. If it is a production order with volume not above 200tons, the delivery time will usually be within 25days after sealing contract. And the delivery time shall be slightly longer for order volume above 200tons.

3.Before cooperation we want a sample for inspecting of quality, is that okay?

We can provide a free sample for you shall sample value not above 30USD, you only need to pay the express charge. For a sample valued more than 30USD, the express charge and just 1 half of sample value is on the account of you, and we afford the other half.

4.Does your company accept third party inspection?

The answer is yes. Especially for new client, they have concern on product quality and quantity, so they authorized the third party inspection like SGS and BV several times to inspect the goods in stead of them, and we coordinated with their work well.

5.Do you accept annual supply order?

Some of our clients purchase annually. They may place order at beginning or certain time of year, however they need us to supply the goods every month or every season. We can do and accept this kind of supplying. We do not ask for the storage charge, however some percentage of deposit will be with us.

6.What documents do you supply for each order?

The documents will usually consist of Original Packing List, Commercial Invoice, Mill Test Certificate, Certificate of Origin, Insurance Policy, and Bill of Loading. Some other documents will be as per client request.

Finally we thank you again that you can visit CZPT Steel, please send your inquiry or comments freely.

We wish you always a beautiful day and in good health!

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Stainless Steel Bars |

|---|---|

| Standard: | ASTM, AISI, GB, JIS |

| Grade: | 200,300,400 Series and Duplex Steel |

| Certification: | ISO, GB |

| Shape: | Round |

| Technique: | Cold-Drawing |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

Can drive shafts be customized for specific vehicle or equipment requirements?

Yes, drive shafts can be customized to meet specific vehicle or equipment requirements. Customization allows manufacturers to tailor the design, dimensions, materials, and other parameters of the drive shaft to ensure compatibility and optimal performance within a particular vehicle or equipment. Here’s a detailed explanation of how drive shafts can be customized:

1. Dimensional Customization:

Drive shafts can be customized to match the dimensional requirements of the vehicle or equipment. This includes adjusting the overall length, diameter, and spline configuration to ensure proper fitment and clearances within the specific application. By customizing the dimensions, the drive shaft can be seamlessly integrated into the driveline system without any interference or limitations.

2. Material Selection:

The choice of materials for drive shafts can be customized based on the specific requirements of the vehicle or equipment. Different materials, such as steel alloys, aluminum alloys, or specialized composites, can be selected to optimize strength, weight, and durability. The material selection can be tailored to meet the torque, speed, and operating conditions of the application, ensuring the drive shaft’s reliability and longevity.

3. Joint Configuration:

Drive shafts can be customized with different joint configurations to accommodate specific vehicle or equipment requirements. For example, universal joints (U-joints) may be suitable for applications with lower operating angles and moderate torque demands, while constant velocity (CV) joints are often used in applications requiring higher operating angles and smoother power transmission. The choice of joint configuration depends on factors such as operating angle, torque capacity, and desired performance characteristics.

4. Torque and Power Capacity:

Customization allows drive shafts to be designed with the appropriate torque and power capacity for the specific vehicle or equipment. Manufacturers can analyze the torque requirements, operating conditions, and safety margins of the application to determine the optimal torque rating and power capacity of the drive shaft. This ensures that the drive shaft can handle the required loads without experiencing premature failure or performance issues.

5. Balancing and Vibration Control:

Drive shafts can be customized with precision balancing and vibration control measures. Imbalances in the drive shaft can lead to vibrations, increased wear, and potential driveline issues. By employing dynamic balancing techniques during the manufacturing process, manufacturers can minimize vibrations and ensure smooth operation. Additionally, vibration dampers or isolation systems can be integrated into the drive shaft design to further mitigate vibrations and enhance overall system performance.

6. Integration and Mounting Considerations:

Customization of drive shafts takes into account the integration and mounting requirements of the specific vehicle or equipment. Manufacturers work closely with the vehicle or equipment designers to ensure that the drive shaft fits seamlessly into the driveline system. This includes adapting the mounting points, interfaces, and clearances to ensure proper alignment and installation of the drive shaft within the vehicle or equipment.

7. Collaboration and Feedback:

Manufacturers often collaborate with vehicle manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft customization process. By actively seeking input and feedback, manufacturers can address specific needs, optimize performance, and ensure compatibility with the vehicle or equipment. This collaborative approach enhances the customization process and results in drive shafts that meet the exact requirements of the application.

8. Compliance with Standards:

Customized drive shafts can be designed to comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, ensures that the customized drive shafts meet quality, safety, and performance requirements. Adhering to these standards provides assurance that the drive shafts are compatible and can be seamlessly integrated into the specific vehicle or equipment.

In summary, drive shafts can be customized to meet specific vehicle or equipment requirements through dimensional customization, material selection, joint configuration, torque and power capacity optimization, balancing and vibration control, integration and mounting considerations, collaboration with stakeholders, and compliance with industry standards. Customization allows drive shafts to be precisely tailored to the needs of the application, ensuring compatibility, reliability, and optimal performance.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2024-02-19

CearaEPT sales made in China – replacement parts – in Bikaner India Coating Aluminum Pulley D120*H22mm for Copper Wire Guide with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Ceramic Coating aluminum pulley

Detailed Product Description:

Aluminium body, surface with chrome ceramic coating

2. High hardness

3. EPT wear resistance

4. Long service life

The ceramic coating aluminum pulley made of aluminum with enameled equipment is easy deformation and the sprayed ceramic coating is failure because of its thin edge and light weight while being sprayed with ceramic rod gun by plasma sprayed facility. Therefore, our company has introduced the whole sets of detonation spraying equipment system.

Specialized for Enameling machine pulleys, the heating to the piece is less during the explosion process but can obtain better high density coating and stronger adhesion.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

Textile wholesaler made in China – replacement parts – in Kahramanmaras Turkey Machinery CNC Machining Belt Pulley with OEM Customized Service with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 various branches. For a lot more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Textile EPT CNC Machining Belt Pulley with OEM/Custom-made Provider

one. Steel machining parts strictly in accordance to customer’s drawing, packing and top quality ask for

two. Tolerance: Can be kept in +/-.01mm

3. The mo EPT innovative CMM inspector to make sure the top quality

4. Seasoned technology engineers and properly skilled personnel

five. Fa EPT and well timed shipping and delivery. Speedily&professional provider

6. Give customer specialist suggestion even though in the method of buyer planning to preserve costs. Our freight price tag is usually thirty-fifty% reduced than customer’s

seven. Customers can use PAYPAL and EPT on-line payment system to pay a modest sum of sample fee to shorten the sample manufacturing time

8. Good quality assurance in accordance with ISO9001: 2008.

Key goods:

cnc cnc device cnc milling device cnc milling equipment cnc mill device cnc lathe cnc lathes cnc parts cnc portion lathe machining 4 axis cnc 5 axis cnc 3 axis cnc cnc producing cnc machine equipment cnc device device cnc tool cnc tools cnc turning 5 axis machining 5 axis cnc device cnc chopping cnc slicing device machining elements machined elements 3 axis cnc milling device cnc machining business cnc prototype machining precision machining large precision machining little cnc milling equipment machining tools machine equipment lathe milling device cnc milling tools cnc providers metallic machining

| Material | Rough Process | Service we provide | Surface treatment | Equipment List | |

| Aluminum 6061/6063/7075 | Die Casting | CNC Machining | Colored Anodize | CNC Milling Machine | |

| ADC12 | Aluminum extrusion | Turning, Milling | Sand Blast | CNC Lathe Machine | |

| ZZnAl4-one | Cast | Sheet Metal Fabrication | Electrical Polish | Grinding Machine | |

| Stainless Steel 304/314/316 | Invest Casting | Welding, Stamping | Zinc/Nickel/Chrome Plate | Drilling Machine | |

| Metal/Carbon Steel | Powder metallurgy | Punching, Drilling | Epoxy Powdering Coat | Polishing Machine | |

| Brass/Copper/Bronze | Plastic injection | Grinding, Polishing | Blacken | Bending Machine | |

| Plastic | Anodizing, Coating | Water transfer | Welding Machine | ||

| Customer request | Customer request | Assembling | Customer request | Wire-slicing | |

| Custom OEM Service | Laser-slicing | ||||

| Water cutting | |||||

| Much more About our Car Machinery | |||||

| Machining | CNCMachine Centre 4-Axis Machining CNC Turning Equipment Milling Machine | ||||

| Tolerance | .005mm | ||||

| Floor Roughness | Ra .8-3.2 | ||||

| Area Treatment method | Sprucing, Nickel plating, Chrome plating, Powder coating, Customized is accessible |

||||

Materials Available:

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | delicate steel, Carbon metal, 4140, 4340, Q235, Q345B, 20#, forty five# and so on. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 and so forth. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 and so forth. |

Surface area Treatment method:

| Aluminum components | Stainless Metal areas | Metal |

| Very clear Anodized | Polishing | Zinc plating |

| Coloration Anodized | Passivating | Oxide black |

| Sandbla EPT Anodized | Sandblasting | Nickel plating |

| Chemical Film | Laser engraving | Chrome plating |

| Brushing | Carburized | |

| Sprucing | Warmth treatment | |

| Chroming | Powder Coated |

one. Q: Why decide on EPT solution?

A: We shengao have our very own plant– HangZhou EPT equipment Co., Ltd, consequently, we can absolutely promise the top quality of every solution and offer you similar price.

2. Q: Do you give EPT Support?

A: Indeed, we offer EPT Provider.

3. Q: Do you give personalized belt pulley?

A: Of course. Buyers give us drawings and specs, and we will manufact appropriately.

four. Q: What is your payment phrase?

A: We offer kinds of payment conditions such as L/C, T/T, Paypal, Escrow, etc.

Textile EPT CNC Machining Belt Pulley with OEM/Tailored Support

If there’s everything I can assist, you should feel totally free to speak to with me.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 distinct branches. For a lot more details: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original equipment manufacturer’s (OEM) component figures or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our firm and the listed substitution components contained herein are not sponsored, approved, or manufactured by the OEM.

China manufacturer & factory supplier for China in Uyo Nigeria manufacturer for Cnc machining belt pulley for sewing machine pulley machinery With high quality best price & service

1 aspect of our software consulting is that we have been collecting and combining the expertise in chain and sprocket purposes in various areas for a long time. This is specifically interesting for us whenever clients method us with some exceeding and demanding specifications.With EPG brand name registered in much more than 70 nations like The us , Europe , Japan and so on, it has partners amid globe best enterprises, these kinds of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so on.

Overview

Fast Details

- Relevant Industries:

-

Production Plant

- Brand Title:

-

OEM

- OEM Provider:

-

Assist

- Tolerance:

-

EPG major manufacturing is of farming fifteen-500 horsepower tractor supporting equipment, mechanical cultivation, harvesting machinery and accessories.

.01-.05mm or Personalized

- Certification:

-

ISO9001, SGS

Provided with hollow shaft. Accessible with cylindrical output shaft.

- Floor Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, and many others.

- Software:

-

Vehicle,Medical Equipments,Electrical Appliance,Hardware,and so forth.

- Dimension:

-

As Customers’ Request

- Tools:

-

Milling/Lathe/Drilling/Four/3 Axis CNC Machining Heart

- Drawing Structure:

-

Pro/E, Auto CAD, Sound Operates,IGS,UG, CAD/CAM/CAE

Supply Capability

- Offer Capability:

- ten thousand Piece/Items per Thirty day period

Packaging & Supply

- Port

- Ningbo

Shear bolt torque limiter (SB) EPG Group delivers large high quality PTO shafts with tubes set by spring pin, cross joints with roller bearings with rollers

Online Customization

Cnc machining belt pulley for stitching equipment pulley machinery

Item Description

|

Solution Kind |

CNC turning, milling, drilling, grinding, wire EDM chopping and so forth. |

|

Our Solutions |

CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Creating,and so forth |

|

Substance |

Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as for every the customers’ requirements |

|

Floor Remedy |

Anodizing,Sandblasting,Portray,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

|

Dimension |

As customers’ ask for |

|

Support Task |

To give manufacturing style, manufacturing and technical support, mould advancement and processing, and so forth |

|

Drawing Structure: |

PRO/E, Auto CAD, Solid Operates,IGS,UG, CAD/CAM/CAE |

|

Testing Machine |

Electronic Height Gauge, caliper, Coordinate measuring device, projection equipment, roughness tester, hardness tester and so on |

|

Business used |

Equipment large duty gear electronic device Auto spare elements optical telecommunication… |

|

Packing |

* Eco-helpful pp bag / EPE Foam /Carton bins or picket boxes |

|

Demo sample time |

7-ten times following affirmation |

|

Shipping time |

7-30 times after receive the pre-payments |

|

Payment Terms |

T/T,Western Union,Paypal |

OEM Services

OEM Parts

Creation Procedure

Surface Treatment method

Why Us

Great price made in China – replacement parts – in Maceio Brazil Pulley Used in Glazing Linecustom Made V Belt Pullay with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Hi, this is Ms Lily from China, we are pulley manufacturer for 25 years worldwide:

| Ca EPT Iron V belt Pulley

1 Material: Ca EPT iron, usually gg20 and gg25 2 Surface treatment: Usually RAL2004 3 Groove sections A, B, and C. 4 Diamater: 80-290 5. tech: sand casting 6.color: any 7. quantity: any |

Glad to know that you are on the markets for our products, we are specializing in auto accessories, machinery parts, construction hardware etc.

Company info:

Our company has gained quality certificate ISO 9001 in 1995. We believe high technology and skilled workers are the key to achieve high performance in quality. We are capable of sand-casting (grey and ductile iron), investment casting (stainless steel, iron and steel),die casting (aluminum), forging,stamping and machining ect.

We can produce various specifications according to customer reque EPT and provide perfect EPT services. If you are interested, please provide us the drawing, requirements and quantity. We shall be pleased to provide you our be EPT prices and deliveries.

Looking for your reply.

Be EPT regards

lily yu

Mbile: 86~13083988828 13858117778735716983

EPT Trade Co.,Ltd.

No.304 Business Shop,Yinxing Road, HangZhou City, ZheJiang , China

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

Xxh400 sales made in China – replacement parts – 500 in Hamadan Iran Steel Cast Iron Timing Pulley with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 different branches. For much more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Overview

———————————————————————————————————————————————————————————————————————————————–

Timing Pulley Figures:XL, L, H, XH & 3M, 5M, 8M, 14M, 20M

Normal Timing Pulleys Introduction:

&Substance:ASTM G-3000 or or C1045 steel,For each and every batch of casting,inspection certificate like chemcial composition, tensile energy, hardness etc will be tested & issued for each batch metal material, subsupplier will supply substance certificate issued by steel plant.

&Machining:Precesion machining for pulley with inventory bore, taper bore .

&Addition:With Flang, and Keystocks when Essential.

&Complete: Black oxide for steel Timing Pulleys,black phosphate for ca EPT iron Timing Pulleys.

&Bundle: Cartons with sealed plastic bag.

Timing Pulleys:Made to Orders’ Prints and/or Samples

EPT Timing Pulleys Introduction:

&Content:Aluminium,Alloy content and so on.

&End:No area remedy,oiled.

&Package: Cartons with sealed plastic bag.

———————————————————————————————————————————————————————————————————————————————–

EPT Ability

EPT Capacity: 20000 Piece/Items for every Thirty day period

Added Service: EPT is welcome

QC Method: ISO9001:2008

———————————————————————————————————————————————————————————————————————————————–

Packaging & Shipping and delivery

Deal: Picket box/Paper carton

Port: HangZhou/ZheJiang or on request

———————————————————————————————————————————————————————————————————————————————–

About EPT since 1984

HangZhou Melchizedek Import & Export Co., Ltd. is a leader manufactur in system subject and punching/stamp

ing area since 1984. Our primary product, NMRV worm equipment velocity reducer and collection helical gearbox, XDR,

XDF, XDK, XDShave achieved the sophisticated strategy index of the congeneric European and Janpanese produc

ts, We provide regular gears, sprockets, chains, pulleys, couplings, bushes and so on. We also can acknowledge orders

of non-normal merchandise, these kinds of as gears, shafts, punching areas ect, in accordance to customers’ Drawings or sam-

ples.

Our business has total established of equipment such as CNC, lathes, milling devices, gear hobbing equipment, g-

ear grinding device, gear honing equipment, gear shaping equipment, worm grinder, grinding devices, drilling m-

achines, boringmachines, planer, drawing benches, punches, hydraulic presses, plate shearing devices and s-

o on. We have sophisticated screening equipments also.

Our organization has proven favorable cooperation relationships with sub-suppliers involving casting, raw mat-

erial, heat remedy, area finishing and so on.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 diverse branches. For a lot more particulars: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of first gear manufacturer’s (OEM) part quantities or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating product use and compatibility. Our firm and the shown replacement elements contained herein are not sponsored, accepted, or made by the OEM.

Wire near me shop made in China – replacement parts – in Mesa United States Pulley of The Cable Pulley with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 various branches. For far more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Wire Pulley Of The Cable Pulley

1.Setting the cable

2.Adjust the angle of the cable

three.Utilized in the engineering machinery

4.Used to support conductors, OPGW,ADSS,conversation lines

| Items title | large cable guidebook pulley |

| Materials | Aluminum |

| Sort | V belt |

| Weight | five.4kg |

| Manufacturer identify | Longtime |

| Packing | Packed in carton,as the customer asked |

| Shipping time | 5-ten days |

Attribute of massive cable guide pulley

1.Can utilized it alone

2.Can used in sequence

3.Adaptability and efficent

four.No operating cost

Manufacturing facility Demonstrate

EPT dimension and materials

Nylon flat belt cable pulley,Nylon V-belt cable pulley,Aluminum flat belt cable pulley, Aluminum V-belt cable pulley,Nylon hanging cable pulley, Aluminum hanging cable pulley

FAQ

one.Q: Are you Trading Company or Factory:

A:. We are manufacturing unit and also Trading Company.

2.Q: What’s your production ability for one month?

A:We can product Metric Tons per Month 200000 pcs .

3.Q: What’s your MOQ?

A:1pc

4.Q:What’s your shipping port?

A:ZheJiang ,ZheJiang or any port as your reqirement

5.Q: What’s your Payment Terms?

A:L/C,T/T,Western Union

Try order is acceptable. Sample is available.

Welcome to inquire, we will feedback within 24 hours.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 diverse branches. For a lot more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of unique products manufacturer’s (OEM) part figures or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our business and the listed alternative elements contained herein are not sponsored, accepted, or manufactured by the OEM.

China manufacturer & factory supplier for double in Bacoor Philippines chain sprocket duplex triplex single roller chain plate wheel gear pulley sheave shaft collar motor base slide sprockets With high quality best price & service

EPG is a major supplier of large good quality, cost-efficient electricity transmission components. As our merchandise lines keep on to expand to fulfill our customer’s wants, our commitment to personalised customer services and on-time shipping and delivery continues to be next to none.We inspect every single piece of bearing by ourselves ahead of supply.

Overview

Fast Details

- Relevant Industries:

-

Manufacturing Plant, roller chain sprocket

- Area of Origin:Zhejiang, China

- Model Title:

-

OEM

- Design Quantity:

-

03/04/05B/06B/08B/10B/12B/16B/20B/24B/28B/32B

Provide Capability

- Provide Potential:

- one million Piece/Items per Month double chain sprocket

Packaging & Delivery

- Packaging Details

- Standard sea worthy package

- Port

- Shanghai or Ningbo

-

Direct Time

: -

Quantity(Bins) 1 – 99999 >99999 Est. Time(times) twelve To be negotiated

On the web Customization

Item Description

sprockets, sprocket for industrial utilization, industrial sprocket, sprocket wheel, pinion, chain wheel, black sprocket, iron sprocket, metal sprocket, c45 sprocket, cast iron sprocket, aluminium sprocket, aluminum sprocket, alumina sprocket, copper sprocket, ss sprocket, stainless steel sprocket, ss304 sprocket, particular sprocket, sprocket with keyway, normal sprocket, sprocket with spline, hardened sprocket, 06B sprocket, 08B sprocket, 10B sprocket, 12B sprocket, 16B sprocket, 20B sprocket, 24B sprocket, 28B sprocket, 32B sprocket, 36B sprocket, 40B sprocket, 48B sprocket, 25 sprocket, 35 sprocket, 40 sprocket, 50 sprocket, 60 sprocket, 80 sprocket, 100 sprocket, 120 sprocket, 140 sprocket, 160 sprocket, a hundred and eighty sprocket, 200 sprocket, 240 sprocket, double solitary sprocket, double chain sprocket, double roller chain sprocket, weld on sprocket

common or specific sprocket as for each your drawing or sample offered

1. Rang of item

03/04/05B/06B/08B/10B/12B/16B/20B/24B/28B/32B

twenty five/35/forty/forty one/fifty/60/eighty/one hundred/a hundred and twenty/one hundred forty/one hundred sixty/180/200/240

two. Max. processing diameter:ø=1450mm

The sequence of concluded-bore sprocket

1. Rang of merchandise

06B/08B/10B/12B/16B/20B/

35/forty/41//fifty/60/80/100/120/a hundred and forty/a hundred and sixty

two. Max. processing diameter:ø=1450mm

Taper bore sprocket of BTL sequence

one. Rang of product

06B/08B/10B/12B/16B/20B

35/40/forty one//50/60/80/one hundred/a hundred and twenty/a hundred and forty/a hundred and sixty

two. Max. processing diameter:ø=1450mm.

Max. coordinated taper bush:8065

Taper bore sprocket of QTL collection

1. Rang of product

35/40/forty one//50/60/80/100/one hundred twenty/140/one hundred sixty/200

2. Max. processing diameter:ø=1450mm.

Max. coordinated QD coverThis way of operating creates synergies among the distinct products if we insert a quite dynamic and specialist coverage, the consequence is a substantial profitability in strategic offers, that warrants the reward of our consumers.:N

STL taper bore sprocket

one. Rang of merchandise

35/40/forty one//50/sixty/eighty/one hundred/120/a hundred and forty/one hundred sixty/two hundred

two. Max. processing diameter:ø=1450mm.

Max. coordinated Browning protect:U2

Molten sprocket wheel

one. Rang of merchandise

06B/08B/10B/12B/16B/20B/24B(technological-bore & BTL taper bore)

We feel honoured to offer you created to purchase product.

2. Max. processing diameter:ø=1450mm. Max. coordinated taper

bush:5050

three. Max. fat of the casting 2000kg.

Coarse pitch conveyor sprocket

1. Rang of product

P50/EPG manufacturer rotocultivator ploughshares in T. line have been picked as the Nationwide Rotary Tillage Machinery Market “Excellent Model Merchandise” in 2007 by Rotocultivator Department of China Agricultural Machinery Industry Affiliation. P75/P100/P50.eight

BTL taper bore sprocket of common sequence

one. Rang of merchandise

06B/08B/10B/12B/16B/20B

35/forty/fifty/60/eighty/a hundred/a hundred and twenty/one hundred forty/160

Flat-prime conveyor sprockets

1. Rang of solution

P 1/2″

Idle gear

one. A PTO shaft transfers the energy from the tractor to the PTO powered attachment. This permits the tractor to electricity a selection of tractor implements including flail mowers, wood chippers, rotary tillers, excavators, and a lot more. Rang of solution

06B/08B/10B/12B/16B

35/40/41/fifty/60/eighty

Worm wheels &Worms

one. Rang of product( Module M1M3,Stress angle20°

two. Rang of solution( diametral pitch 4DP16PD,

Pressure angle14.5°

Cylindrical spur gears

one. Rang of solution( Module M1M6,Pressure angle20° Pierce

two. Rang of solution( diametral pitch 4DP16PD,Stress angle20°/14.5°. STL taper bore

Straight bevel gear

1. Rang of item( Module M1.5M5,Force angle20° Pierce

two. Rang of merchandise( diametral pitch 4DP16PD,Pressure angle20°/fourteen.5° STL taper bore

Major Merchandise

Company Details

Exhibition

Speak to Us

Wholesale Cheap made in China – replacement parts – in Banjarmasin Indonesia Price High Precision Aluminum Timing Belt Pulley with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Wholesale price High precision Aluminum Timing Belt Pulley

Main Features:

1. EPT tooth number from 14 to 72 timing pulley

2. Material can be designed by customer requirement

3. High torque series S2M S3M S5M S8M P2M P3M P5M P8M

4. Normal torque series MXL XL L H

5. High precision drive series 2GT 3GT 5GT 8YU

6. Light load drive series T5 T10

7. Heave load drive series AT5 AT10

8. Clamping Timing Pulleys S3M S5M S8M

| Type | Timing pulley adapt to 1/4 inch, 5/16 inch, 3/8 inch, 1/2 inch belt. |

| Specification | Standard or Customed |

| Material | Stainless steel,Brass, Carbon steel, Aluminum, and so on. |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,Gear Shaving, Gear Grinding and Gear Lapping |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, Copper-plating, the wreath oxygen resin spraying, black oxide coating, painting, powdering, color zinc-plated,blue black zinc-plated, silver plating,anodizing etc. |

| Producing Equipment | CNC machine , automatic lathe machine,stamping machine,CNC milling machine,rolling machine, lasering, tag grinding machine etc. |

| Management System | ISO9001 – 2008 |

| Testing Equipment | Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester, 2D projector |

Application:

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

High near me made in China – replacement parts – in Matamoros Mexico Performance Short Water Pump Single Belt Groove Pulley, Aluminum Water Pump Pulley with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

High performance short water pump single belt groove pulley, aluminum water pump pulley

Surface: As your requirement

Material: Steel / aluminum / brass / iron / zinc / alloy

Any EPT material and dimension depends on customers’ demand.

Industry Focus Appliance/ Automotive/ Agricultural Electronics/ Industrial/ EPT Mining/ Hydraulics/ Valves Oil and Gas/ Electrical/ Construction

Industry Standards ISO 9001: 2008 PPAP Ro EPT Compliant

Additional Capabilities C EPT Design Services CAM Programming Services Coordinate Measuring Machines (CMM) Reverse Engineering

| Specification |

High performance short water pump single belt groove pulley, aluminum water pump pulley |

| Material | Stainless steel, copper, brass, carbon steel, aluminum (according to customer’s requirement. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, ru EPT preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Main Products | Precision screw,bolt, nuts,fastener,knob,pins, bushing, sleeve,gear, stamping parts,washer,gasket, plastic molding injection parts, standoff,CNC machining service,accessories etc. |

| Producing Equipment | CNC machine , automatic lathe machine,stamping machine,CNC milling machine,rolling machine,lasering,tag grinding machine etc. |

| Management System | ISO9001 – 2008 |

| Available Certificate | RoHS, SGS, Material Certification |

| Testing Equipment | Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester , 2D projector |

| Lead time | 10-15 working days as usual,It will based on the detailed order quantity. |

| Managing Returned Goods | With quality problem or deviation from drawings |

| Delivery of Samples | By DHL,Fedex,UPS, TNT,EMS^^ |

| Warranty | Replacement at all our co EPT for rejected products |

| Main Markets | North America, South America, EPT Europe , We EPT Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! | |

| Applications | Toy,Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, light industry products, sanitation machinery, market/ hotel equipment supplies, artware etc. |

SUS303 & SUS 304 Stainless Steel Machining:

As well as reducing the corrosion resistance, the sulphur additions in 303 also result in poor weld ability and reduced form ability compared to Grade 304. Sharp bends should not be attempted in 303. A practical compromise alternative may be a 304 Ugima Improved Machining ability grade – this does not machine as readily as 303, but does offer better form ability (as well as better weld ability and corrosion resistance).

Heat Treatment:

Solution Treatment (Annealing) – Heat to 1571-1120°C and cool rapidly. This grade cannot be hardened by thermal treatment.

Machining:

A “Ugima” improved machinability version of grade 303 is available in round bar products. This machines significantly better even than standard 303, giving very high machining rates and lower tool wear in many operations.

Characteristics & Function of CNC Machining Stainless Steel:

SUS 303:

Nuts and Bolts, Bushings, Shafts, Aircraft Fittings, Gears.

Electrical Switchgear Components.

In general any component that is heavily machined and where the corrosion resistance and fabrication properties of 303 are viable.

SUS 304:

Food processing equipment, particularly in beer brewing, milk processing & wine making.

Kitchen benches, sinks, troughs, equipment and appliances.

Architectural panelling, railings & trim.

Chemical containers, including for transport.

Heat Exchangers.

Woven or welded screens for mining, quarrying & water filtration.

Threaded fasteners, Springs.

SUS 316:

Food preparation equipment particularly in chloride environments.

Laboratory benches & equipment, Threaded fasteners, Springs.

Coastal architectural panelling, railings & trim.

Boat fittings, Chemical containers, including for transport.

Heat Exchangers, Woven or welded screens for mining, quarrying & water filtration.

316 Higher resistance to pitting and crevice corrosion is required, in chloride environments. A lower machining ability can be accepted.

SUS 416:

Valve Parts, Pump Shafts, Automatic Screw Machined Parts.

Motor Shafts, Washing Machine Components.

Bolts and Nuts, Studs, Gears.

Even higher machining ability than 303 is needed, and a lower corrosion resistance can be tolerated. Or hardening by thermal treatment is required, while maintaining a high machining ability.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.